Manufacturing method of three-section type oxide layer shielding gate trench MOSFET structure

A manufacturing method and oxide layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems hindering the development of advanced SGT, achieve good high-temperature reflow characteristics, good trench filling ability, and reduce device Rsp Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in combination with specific embodiments.

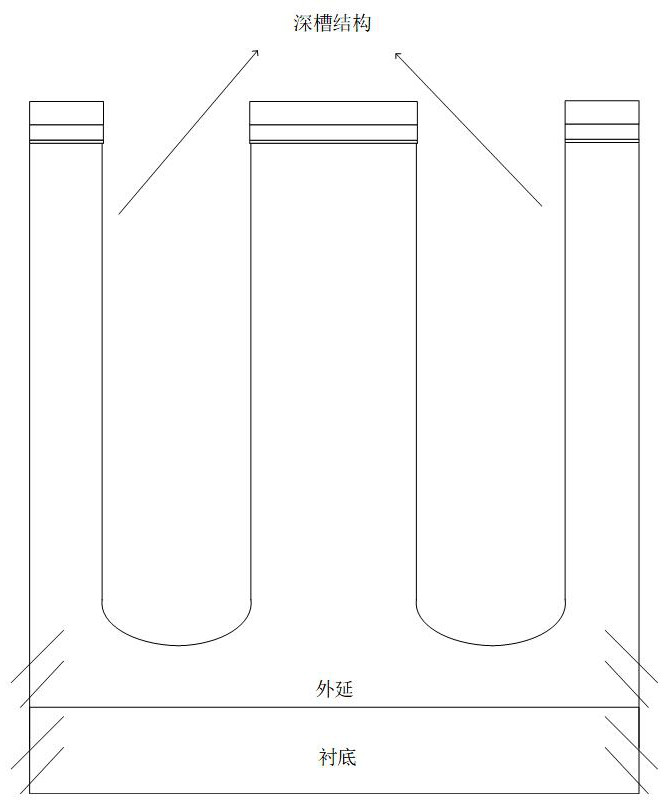

[0050] The invention relates to a method for manufacturing a three-stage oxide layer shielding gate trench MOSFET structure. The method uses a CVD process to fill a deep trench with borosilicate glass BSG material, and then makes the borosilicate glass BSG material in the borosilicate glass BSG material through a thermal process. Boron diffuses into the Si material around the deep trench to form P columns, and changes the BSG concentration and annealing temperature to adjust the height, width and concentration of P columns to achieve charge balance with the N-type epitaxial layer.

[0051] Specifically include the following steps:

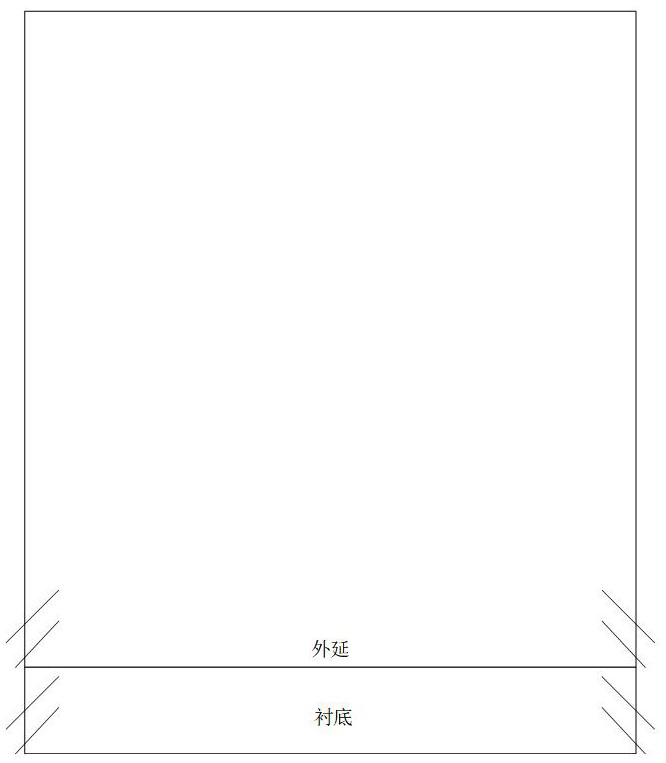

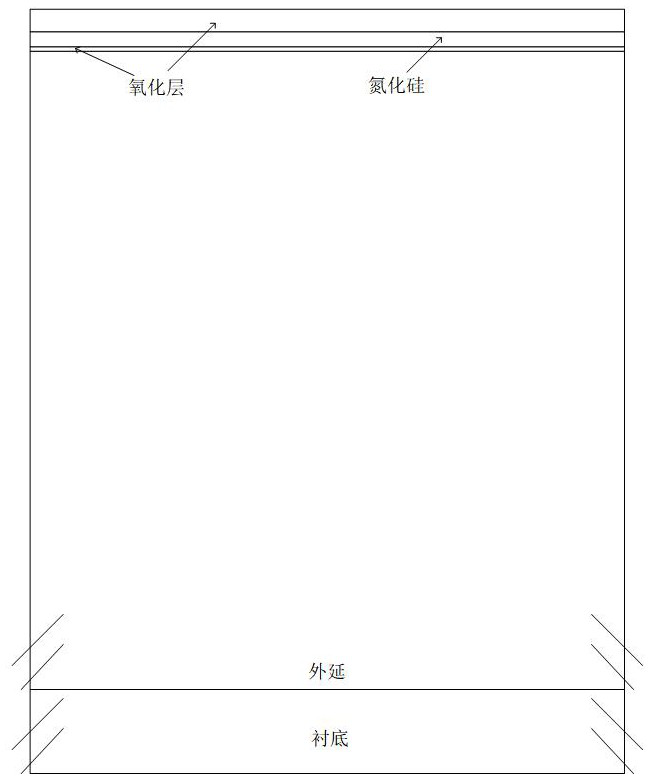

[0052] Step 1: grow an N-type epitaxial layer on the surface of the Si substrate, and the thickness of the epitaxial layer is determined according to the source-drain withstand voltage required by the device, ranging from 5 microns to 20 micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com