Three-section type oxide layer shielding gate trench MOSFET structure

A technology of oxide layer and shielding grid, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems that hinder the development of advanced SGT

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in combination with specific embodiments.

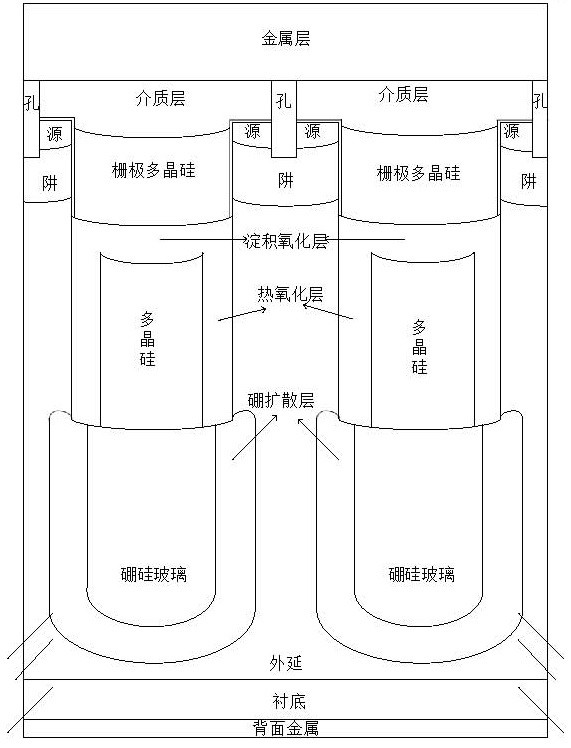

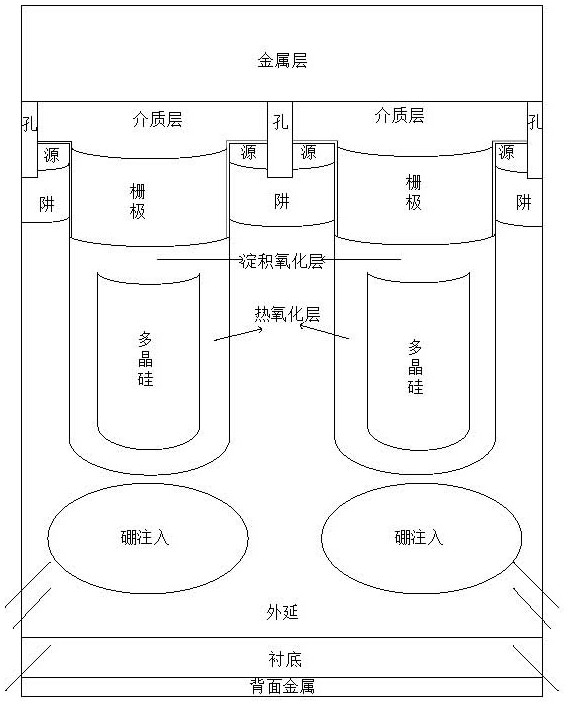

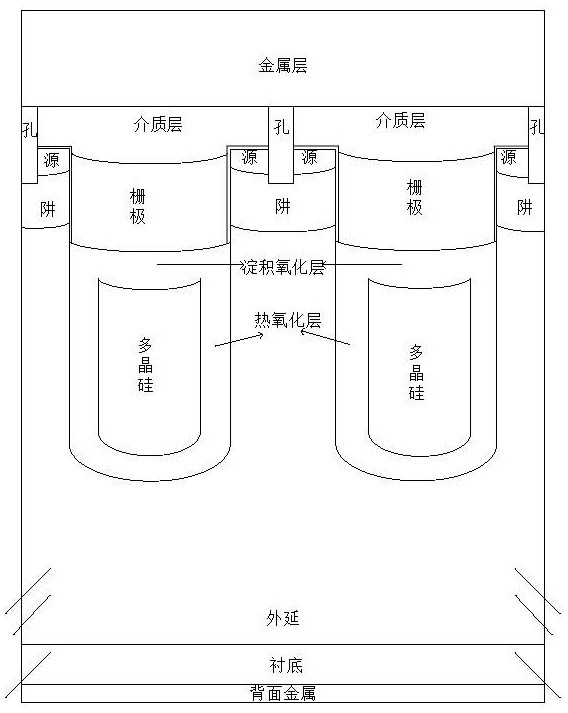

[0024] The invention relates to a three-stage oxide layer shielded gate trench MOSFET structure. The MOSFET structure is located on an epitaxial substrate, and there is an area under the source trench, which is filled with a material inverse to the epitaxial line and thereby P-column and epitaxy formed by diffusion source diffusion to achieve charge balance.

[0025] The region under the source trench of the MOSFET structure is a deep trench. The filling material area in the deep trench is narrow in width and high in height, the width is in the range of 0.2-2 microns, the height is in the range of 0.5-17 microns, and the depth below the Si surface is between 2 microns and 17 microns. The depth of the deep trench is less than the thickness of the epitaxy on which the MOSFET structure is located.

[0026] The surfaces on both sides of the filling material region in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com