Copper interconnecting structure and preparation method thereof

A copper interconnection structure and adhesion layer technology, applied in the field of microelectronics technology, can solve problems such as barrier failure, and achieve the effects of ensuring reliability, good trench filling capability, and low resistivity

Inactive Publication Date: 2013-01-30

FUDAN UNIV

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, a single layer of Ru is not suitable as a diffusion barrier, because experiments have shown that the Ru monolayer diffusion barrier will fail after annealing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

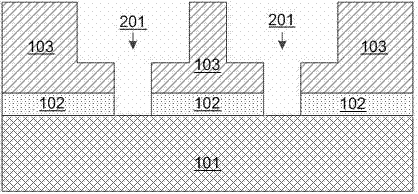

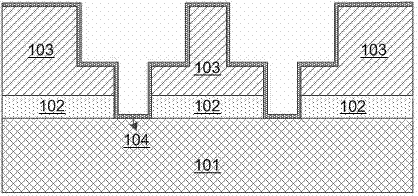

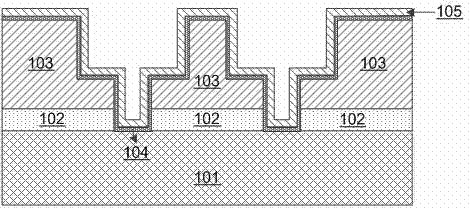

The invention belongs to the technical field of microelectronic technology, and particularly provides a copper interconnecting structure with Ru-Al-O served as a diffusing and adhering resisting layer, and a preparation method. According to the copper interconnecting structure, the conventional copper interconnecting structure is served as the basis, and conventional TaN / Ta double-layer structure is replaced by the Ru-Al-O, and the Ru-Al-O is served as the new copper diffusing resisting layer of the copper interconnecting structure. According to the preparation method, an atomic layer deposition (ALD) method is carried out to deposit a Ru-Al-O layer with thickness of 3 to 5nm on the upper layer of a thermally oxidized silica film to be served as an adhering layer, and a Ru layer with thickness of 5 to 10nm is formed on the adhering layer to be served as the diffusing resisting layer as well as a seed crystal layer of electroplating copper. The ratio of Ru to Al to O in the Ru-Al-O can be adjusted, so as to obtain higher resistance to copper diffusion and adhering property. By adopting the copper interconnecting structure, the adhering strength of the diffusing resisting layer and the silica layer at the lower layer can be improved, and the tightness under connection with the seed crystal layer can be kept; and an improved feasible program is provided for conventional copper interconnecting technology to improve the adhering capacity.

Description

technical field [0001] The invention belongs to the technical field of microelectronic technology, and specifically relates to a novel copper interconnection structure and a preparation method using a Ru-Al-O\Ru laminated structure as a diffusion and adhesion barrier layer. Background technique [0002] In the copper interconnection process, in order to prevent Cu from diffusing into Si devices and causing damage to device performance, it is necessary to wrap a diffusion barrier layer outside the copper interconnection to isolate Cu and SiO. 2 , Si, and the effect of improving the adhesion between Cu and them. The double-layer structure of TaN / Ta in the traditional process has been widely used. However, with the reduction of the device size, when the feature size is less than 45nm, in order to ensure that the copper interconnection can still have a good filling effect, the diffusion barrier layer The challenge is to have a thinner thickness and still have a strong barrier e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L23/532H01L21/768

Inventor 卢红亮张卫谢立恒丁士进王鹏飞

Owner FUDAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com