High-thermal-conductivity microwave TR assembly packaging shell and processing method thereof

A technology for packaging shells and processing methods, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of unevenness of signal terminals in package shells, improve heat dissipation capability and packaging reliability, Improve the processing technology and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

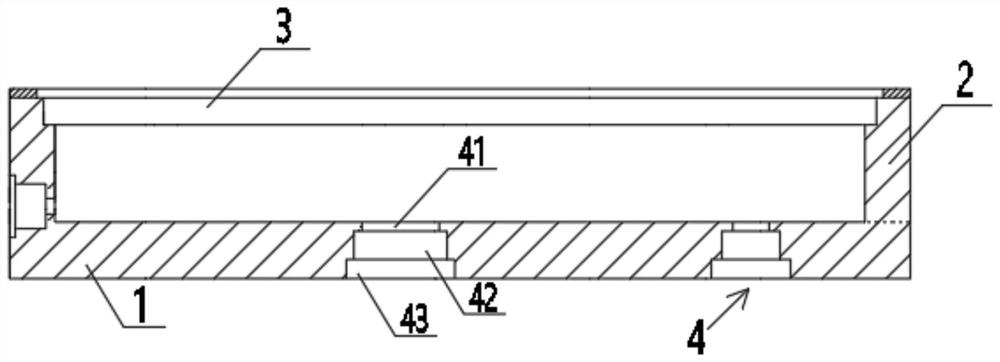

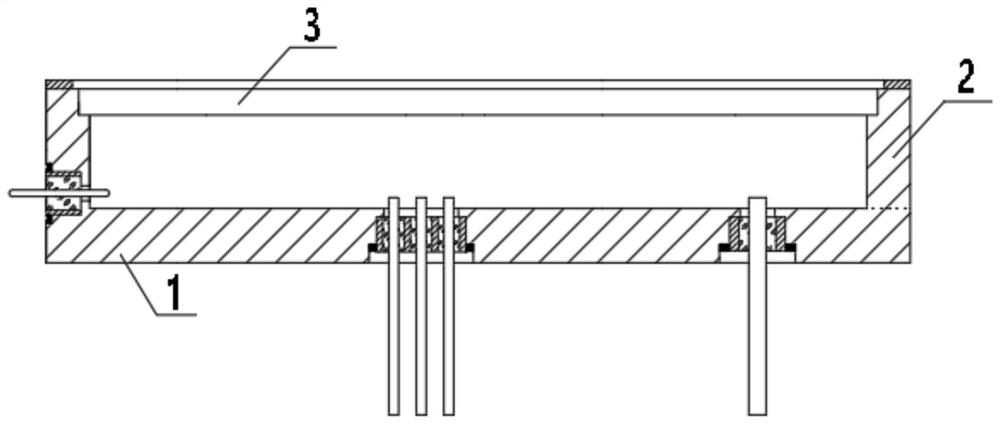

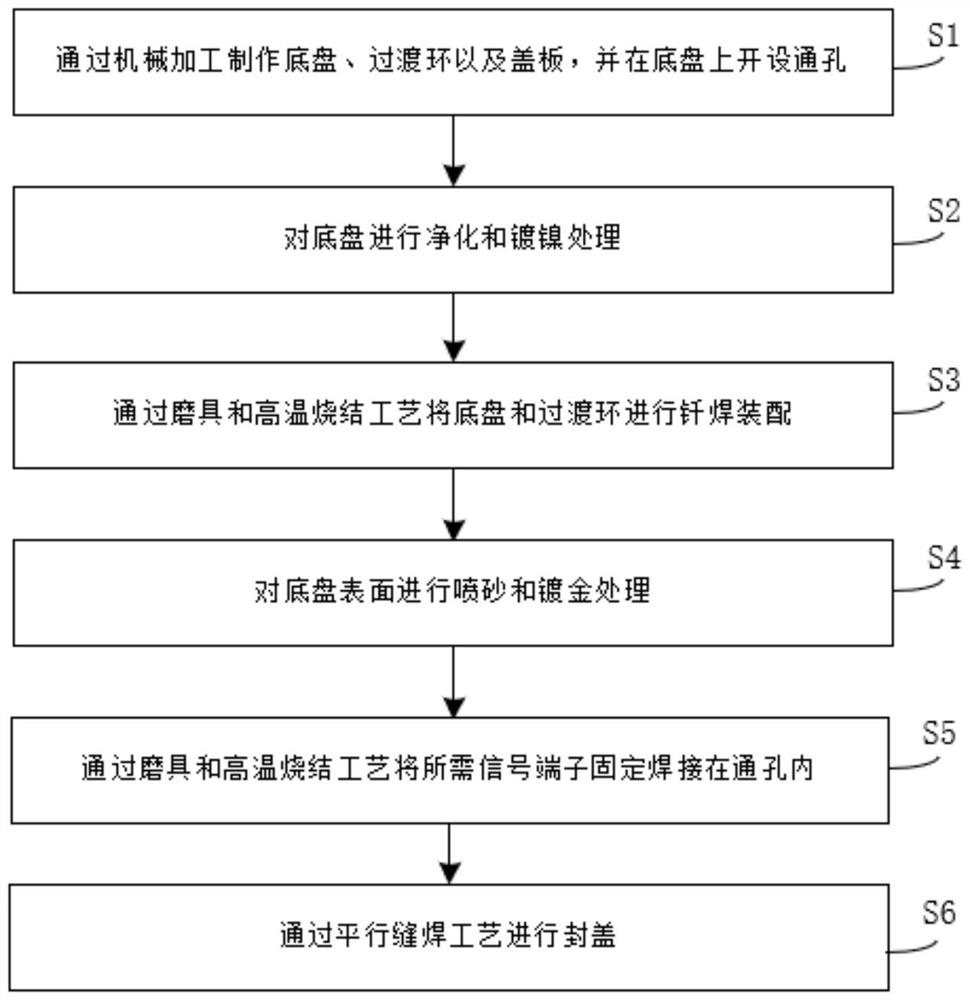

[0026] Such as figure 1 A high thermal conductivity microwave TR component package housing shown includes a chassis 1, a transition ring 2 and a cover plate 3, the chassis and cover plate are made of Mu / Cu material, the transition ring is made of Kover material, and the chassis is provided with Several through-holes 4 for soldering radio signal terminals, the through-holes adopt a three-stage stepped cavity structure with a larger diameter from the inside to the outside, including a first-stage step 41, a third-stage step 42 and The second step 43 is used to control the verticality of the signal terminal.

[0027] Mu / Cu material is a material with high thermal conductivity, its thermal conductivity can reach 220W / m*K, and its thermal expansion coefficient is 7.7ppm / ℃, so it has excellent high temperature resistance, radiation resistance and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com