Evaporation pipe structure for engine combustion chamber, combustion chamber device and preparation method

A technology of evaporating tubes and combustion chambers, which is applied in the direction of combustion methods, combustion chambers, combustion equipment, etc., can solve problems such as inability to meet higher requirements, achieve the effects of reducing the probability of ablation, uniform distribution of oil and gas, and strengthening air turbulence disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in further detail below in conjunction with accompanying drawing:

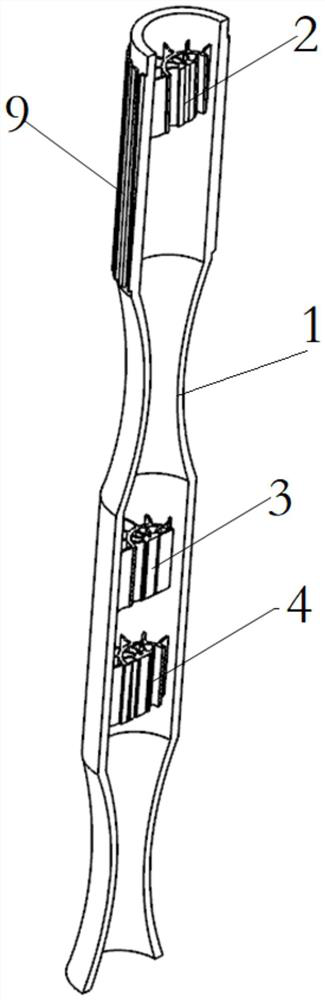

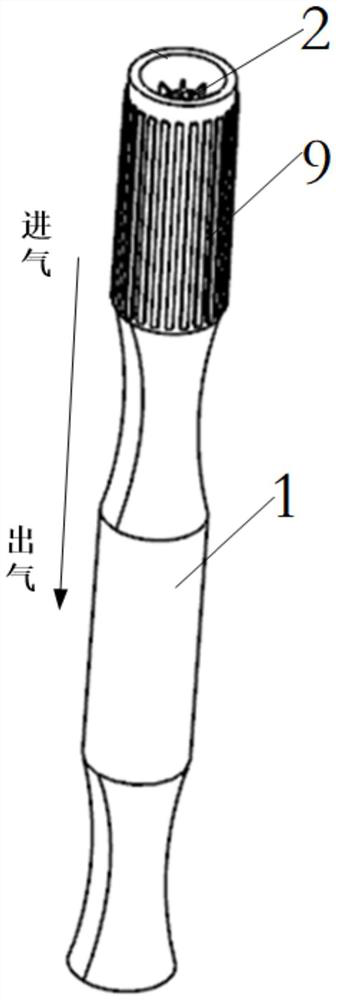

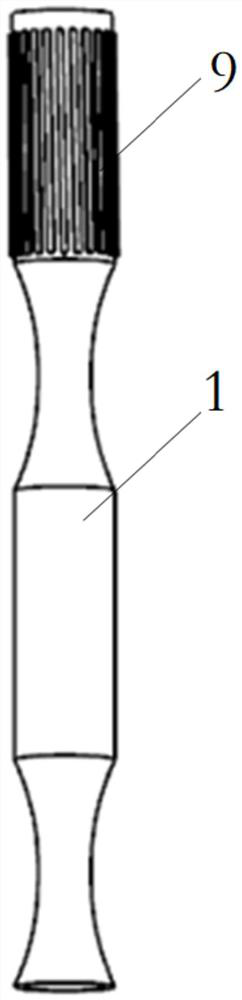

[0046] Such as Figure 1 to Figure 4 As shown, an evaporator tube structure for an engine combustion chamber includes an evaporator tube body 1, and the evaporator tube body 1 includes a first cylindrical section, a concave curved surface section, a second cylindrical section, and an outlet in sequence from the air inlet end to the air outlet end. section; the first cylindrical section is provided with a first double cyclone 2 whose axis is parallel to the axis of the evaporation tube body 1, and the second cylindrical section is provided with a second double cyclone whose axis is parallel to the axis of the evaporation tube body 1 device 3 and the third double cyclone 4, the second double cyclone 3 and the third double cyclone 4 are arranged at intervals along the axial direction of the evaporation tube body 1, such as Figure 9 As shown, the blades of two adjacent d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com