Hydrogen radical shaft furnace direct reduction system and method

A shaft furnace, direct technology, applied in the hydrogen-based shaft furnace direct reduction system and the field of reduction, can solve the problems of complex cooling gas circulation system, uneven reduction of oxidized pellets, high energy consumption, etc., to achieve uniform reduction and energy saving Visible, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

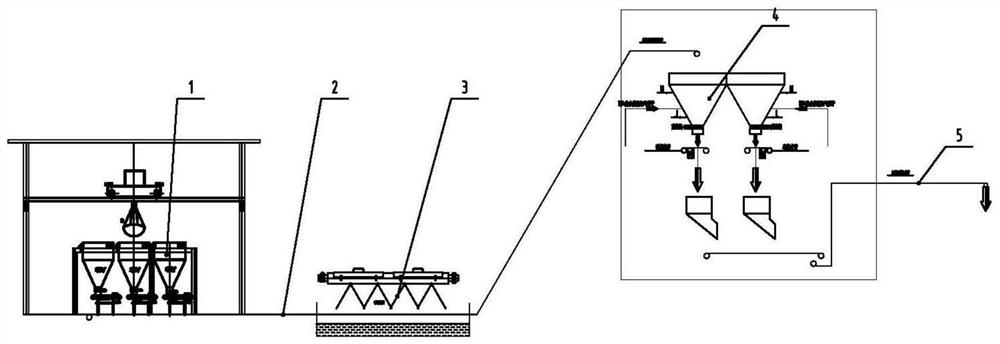

[0069] This embodiment provides a hydrogen-based shaft furnace direct reduction system, such as Figure 1 to Figure 11 As shown, it includes a shaft furnace body and a hydrogen-rich heater heating unit (see embodiment 2 for the specific structure of the hydrogen-rich heating unit); wherein, the shaft furnace body includes an oxidation pellet 1 reduction unit and a cooling unit in the metal pellet furnace; The reduction unit of the pellet 1 includes a shaft furnace reduction section 11, a reduction mixed gas section located below the shaft furnace reduction section 11, and a hollow shaft furnace central cone 14; the outer side of the shaft furnace reduction section 11 is provided with a high-temperature hydrogen-rich reducing gas annular gas chamber 12. The annular gas chamber communicates with the reducing gas mixing section through the high-temperature hydrogen-rich reducing gas nozzle 13 arranged in the circumferential direction; the cooling unit in the metal pellet furnace i...

Embodiment 2

[0092] This embodiment provides a hydrogen-rich reducing gas heater 48, such as Figure 12-15 As shown, including the heater body, the heater body (heater flue gas chamber) includes the heater sub-box and the flue gas inlet and flue gas outlet arranged at both ends of the heater body; the heater sub-box is provided with interconnected The high-temperature section heating tube bundle, the medium-temperature section heating tube bundle and the low-temperature section heating tube bundle; the hydrogen-rich reducing gas 45 passes through the low-temperature section heating tube bundle, the medium-temperature section heating tube bundle and the high-temperature section heating tube bundle to realize the reverse exchange with the flue gas in the heater sub-box. hot.

[0093] Specifically, the heater body provided by the present invention includes a plurality of heater sub-boxes, the interior of the heater sub-boxes is hollow, and the two ends of the heater sub-boxes are respectively...

Embodiment 3

[0115] This embodiment adopts the hydrogen-based shaft furnace direct reduction system provided in Embodiment 1, see figure 1 , specifically includes the following processes: feeding process of oxidation pellet 1, reduction process of oxidation pellet 1, metal pellet cooling process, metal pellet discharge process top gas release process, hydrogen-rich reducing gas heating process and gas supply process.

[0116]Feeding process of oxidized pellets 1: firstly, it is necessary to coat the surface of oxidized pellets 1 entering the furnace to prevent surface adhesion of the pellets entering the shaft furnace for reduction; oxidized pellets 1 are used to ensure that the pellets Strength in the shaft furnace to prevent pulverization; the oxidized pellets 1 are weighed and unloaded from the raw material warehouse into the pellet surface coating feeding mesh belt 2, and the pellets are sprayed on the mesh belt by the surface spraying device 3, and the surface is sprayed The final pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com