Talcum powder filled foaming master batch and preparation method thereof

A technology of foaming masterbatch and talcum powder, which is applied in the field of plastic material modification, can solve the problems of increasing the density and weight of modified material products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

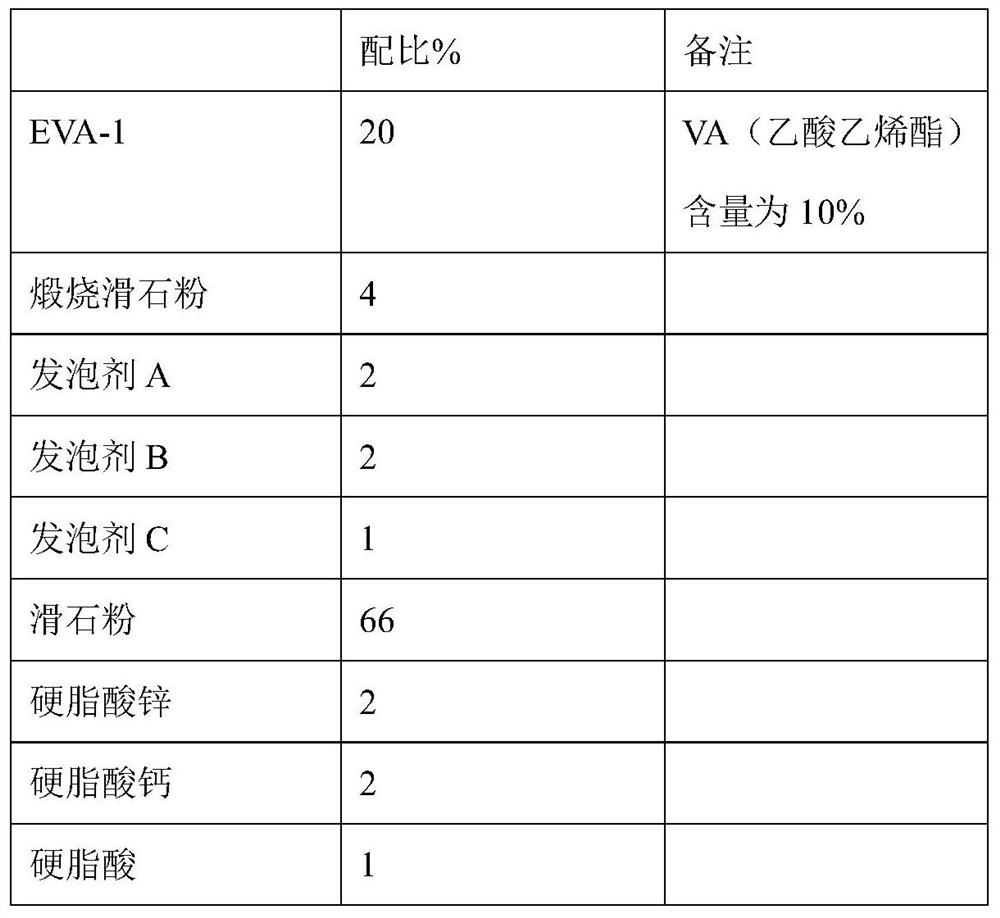

[0033] A kind of talcum powder filling foam masterbatch, its formula is as follows

[0034]

[0035] The preparation method of the talcum powder filling foaming masterbatch of the present embodiment is:

[0036] 1) Add 660g of talc powder, 20g of foaming accelerator zinc stearate, 20g of processing lubricant calcium stearate, and 10g of processing heat stabilizer stearic acid into the mixer and mix evenly, then heat to 75-78°C After fully activating the powder, add 20g of AC foaming agent, 20g of OBSH foaming agent, 10g of phenylsulfonyl hydrazide and 40g of calcined talcum powder as a nucleating agent, mix for another 5 minutes, and finally add 200g of resin and mix for 12 minutes;

[0037] 2) Put the mixed material into a single-screw granulator to granulate, and the extrusion temperature is 120-123°C to obtain the existing product.

Embodiment 2

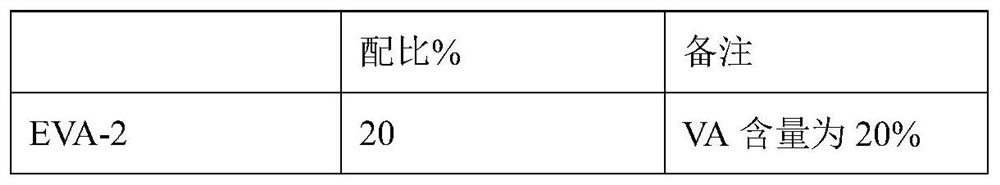

[0039] A kind of talcum powder filling foam masterbatch, its formula is as follows

[0040] Proportion % Remark EVA-2 20 VA content is 20% Calcined Talc 4 Blowing agent A 1 Foaming agent B 1 Blowing agent C 1 talcum powder 68 Zinc stearate 1 Calcium stearate 2 stearic acid 2

[0041] The preparation method of the talcum powder filling foaming masterbatch of the present embodiment is:

[0042] 1) Add 680g of talc powder, 10g of foaming accelerator zinc stearate, 20g of processing lubricant calcium stearate, and 20g of processing heat stabilizer stearic acid into the mixer and mix evenly, then heat to 78-82°C Finally, fully activate the powder, then add 10g of AC foaming agent, 10g of OBSH foaming agent, 10g of phenylsulfonyl hydrazide and 40g of calcined talc powder as a nucleating agent, mix for another 5 minutes, and finally add 200g of resin and mix for 12 minutes;

[0043] 2) Put the m...

Embodiment 3

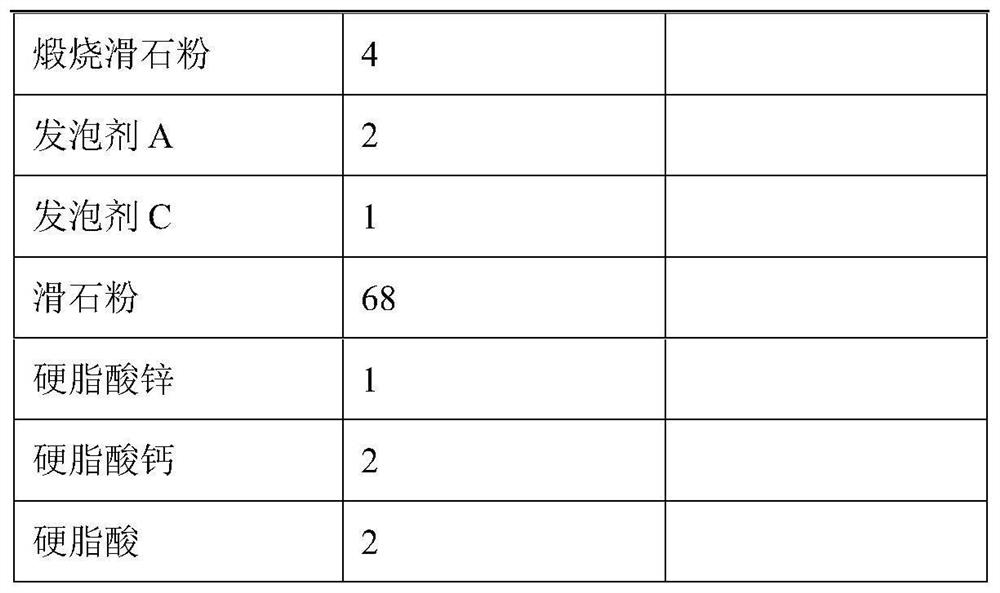

[0062] A kind of talcum powder filling foaming masterbatch, its formula is as follows:

[0063] Proportion % Remark EVA-3 20 VA content is 40% Calcined Talc 2 Blowing agent A 1 Foaming agent B 1 Blowing agent C 1 talcum powder 70 Zinc stearate 2 Calcium stearate 1 stearic acid 2

[0064] The preparation method of the talcum powder filling foaming masterbatch of the present embodiment is:

[0065] 1) Add 700g of talc powder, 20g of foaming accelerator zinc stearate, 10g of processing lubricant calcium stearate, and 20g of processing heat stabilizer stearic acid into the mixer and mix evenly, then heat to 82-85°C After fully activating the powder, add 10g of AC foaming agent, 10g of OBSH foaming agent, 10g of phenylsulfonyl hydrazide and 20g of calcined talcum powder as a nucleating agent, mix for another 4 minutes, and finally add 200g of resin and mix for 10 minutes;

[0066] 2) Put the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com