Floating material and heavy metal-contaminated soil remediation method and application based on floating material

A technology of floating materials and repair methods, applied in the field of heavy metal contaminated soil remediation, can solve the problems of secondary pollution, difficult to recycle, re-release of cadmium, etc., to achieve the effect of enhancing binding ability, promoting dispersion ability, and enhancing soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Weigh 50 g of coconut shell raw material with particle size of 1~2 mm, place it in 1 L of 10% H 3 PO 4 In the solution, after stirring for 30 min, washed with deionized water until neutral, dried at 60 °C for 24 h, and then placed 10 g of the dried material in 1000 mL of 1.0 g / L Ca of ultrasonic dispersion. 10 (PO 4 ) 6 OH 2 The solution was stirred at room temperature for 2 h. Filter and dry to obtain solid raw materials. The solid raw materials were then placed in a tube furnace, and pyrolyzed at 500 °C, 550 °C, and 600 °C for 1 h, and N was introduced into the furnace. 2 , N 2 The rate was 500 mL / min and the heating rate was 10°C / min to obtain a floating material.

[0051] After grinding and sieving the above floating materials, the specific surface area and pore size of the biochar were characterized by a specific surface area analyzer (BET), and the pretreatment temperature was set to 350 °C.

[0052] The characterization results show that the specific surf...

Embodiment 2

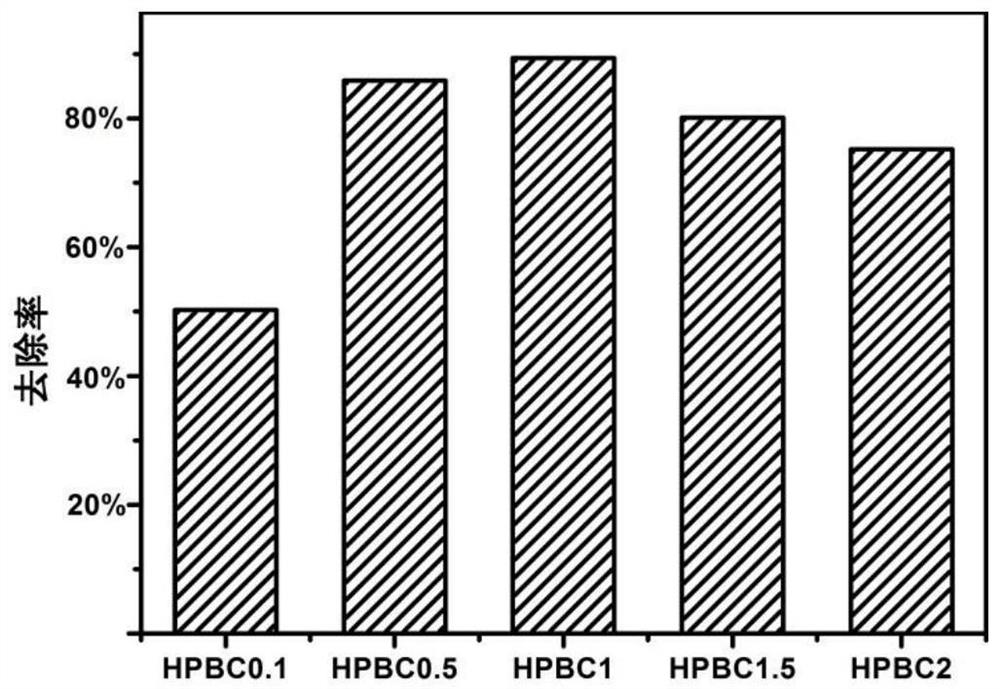

[0054] Weigh 50 g of coconut shell raw material with particle size of 1~2 mm, place it in 1 L of 10% H 3 PO 4 In the solution, after stirring for 30 min, washed with deionized water to neutrality, dried at 60 °C for 24 h, respectively added 10 g of the dried material and placed in 1000 mL of 0.1 g / L, 0.5 g / L ultrasonically dispersed, 1.0 g / L, 1.5 g / L, 2.0 g / L of Ca 10 (PO 4 ) 6 OH 2 The solution was stirred at room temperature for 2 h. Filter and dry to obtain solid raw materials. The solid raw materials were then placed in a tube furnace, and pyrolyzed at 500 °C for 1 h. 2 The heating rate was 500 mL / min and the heating rate was 10 °C / min to obtain floating materials HPBC0.1, HPBC0.5, HPBC1, HPBC1.5, and HPBC2 with different properties.

[0055] 30 mg of floating materials with different ratios were respectively placed in 30 mL and 50 mg / L Cd solution, shaken at room temperature for 12 h, 150 rpm, sampled to measure the Cd concentration of the supernatant, and the remo...

Embodiment 3

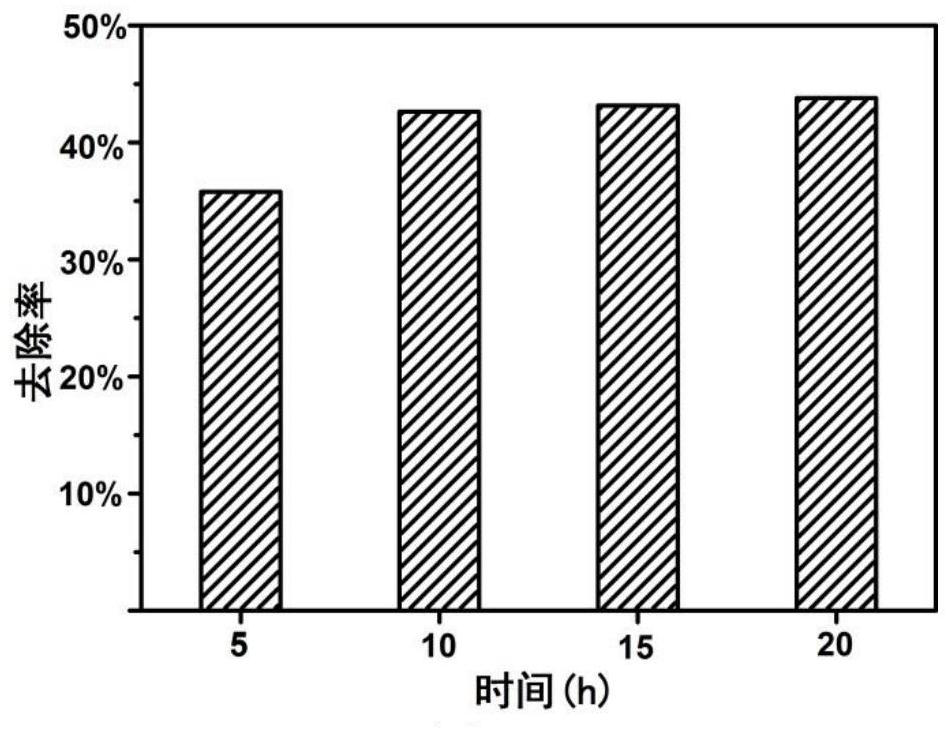

[0066] The effect of different reaction times on the removal of Cd from floating materials was measured. 100 g of naturally air-dried paddy soil with a Cd concentration of 1.2 mg / kg was weighed and placed in a 1 L beaker. Add 2 g of floating material to the Cd-contaminated soil, add a small amount of water, soak the soil and the floating material, so that the floating material and the cadmium-contaminated soil are fully mixed. After standing for 5 d, 10 d, 15 d and 20 d, add ultrapure water 5-8 cm above the soil interface, stir well to make all the materials float, and then use the fishing net to recover, and remove the upper layer of mud-water mixture. The experiment was set up in parallel with three groups. Calculate the removal rate of total cadmium, the result is as follows image 3 shown.

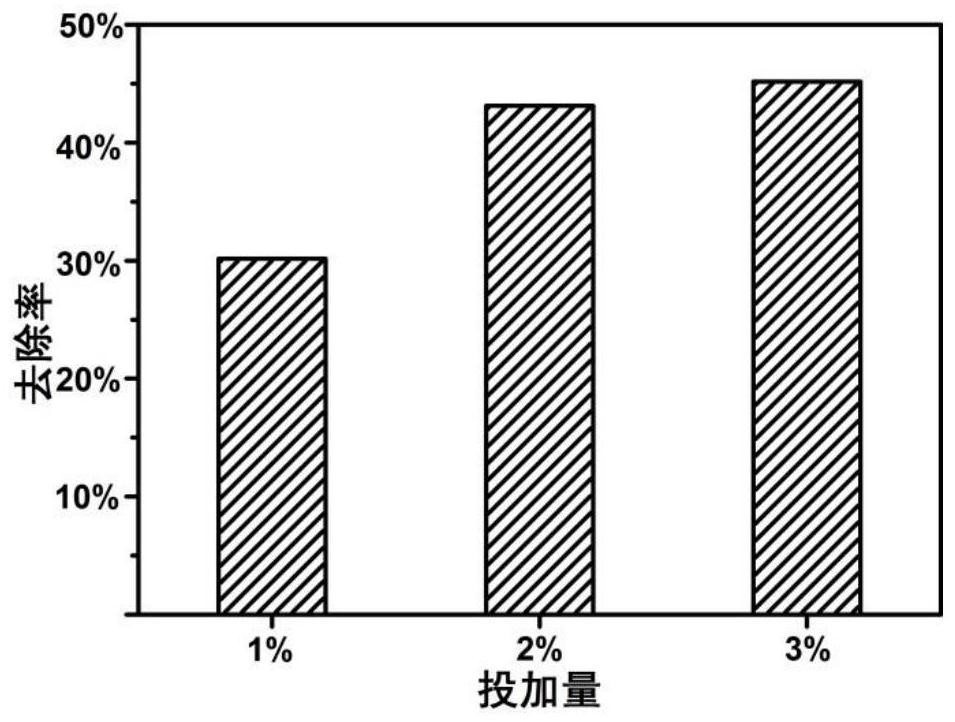

[0067] The effects of different dosages on the removal of Cd from floating materials were weighed and 100 g of paddy soil with a natural air-dried Cd concentration of 1.2 mg / kg was w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com