Polyester resin composition, member for light reflectors containing same, and light reflectors

A technology of polyester resin and composition, which is applied in the field of polyester resin composition to achieve the effects of good surface smoothness, suppression of flow marks and low gas properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

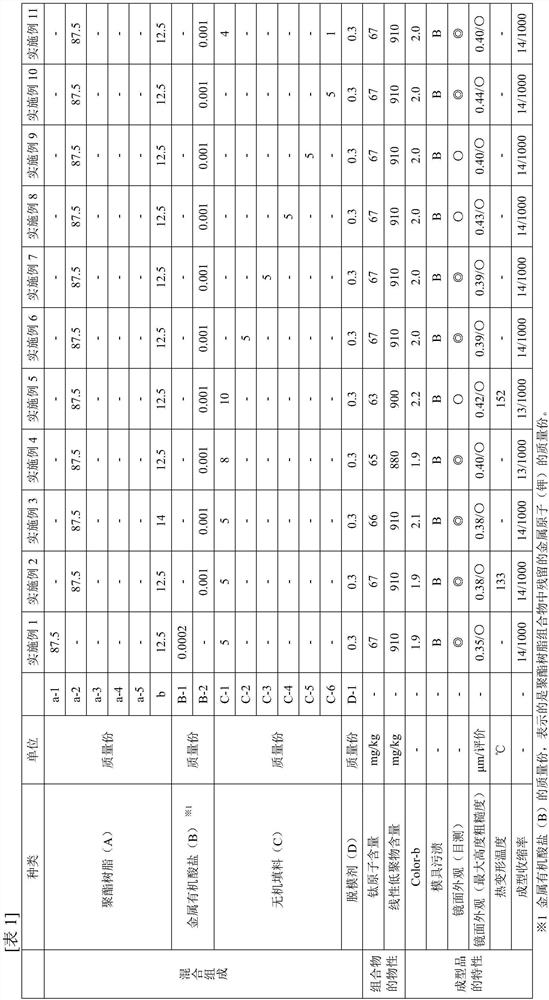

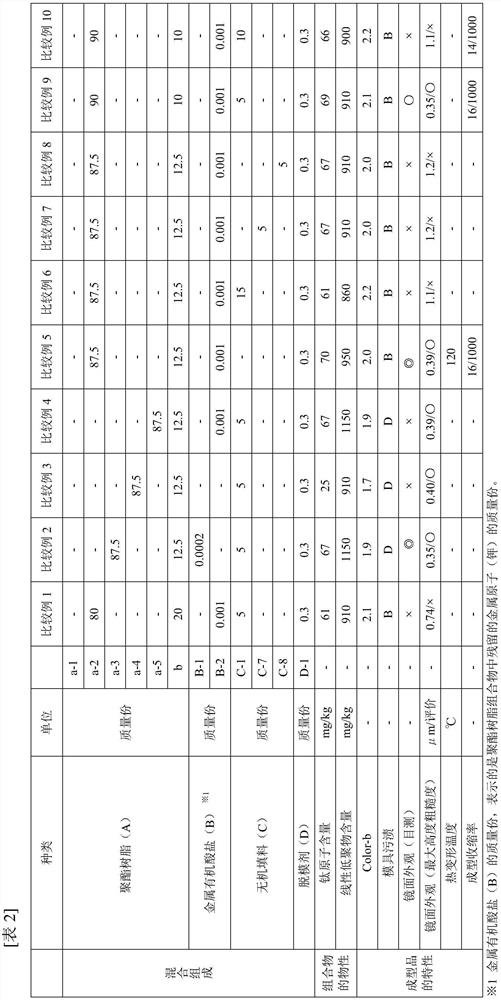

Embodiment 1~11、 comparative example 1~10

[0179] The mixed components mixed according to the combinations shown in Tables 1 and 2 were kneaded by a co-direction twin-screw extruder with the barrel temperature set at 260°C, and the obtained strands were cooled with water and pelletized. The obtained pellets were dried at 130° C. for 4 hours to obtain polyester resin compositions corresponding to each Example and each Comparative Example. With respect to these polyester resin compositions, each of the above-mentioned evaluation tests (4) to (10) was implemented.

[0180] Regarding the amount of the metal organic acid salt B, in the examples and comparative examples where the metal organic acid salt B was added at the time of melt polymerization (after the esterification reaction), compared with the amount at the time of addition, the polyester resin composition after melt kneading The residual amount (content) in the product decreased (it is considered that it may be distilled during the decompression step in the later ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com