Full-fluorescence type white light organic light emitting diode and preparation method thereof

A light-emitting diode and fluorescent technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

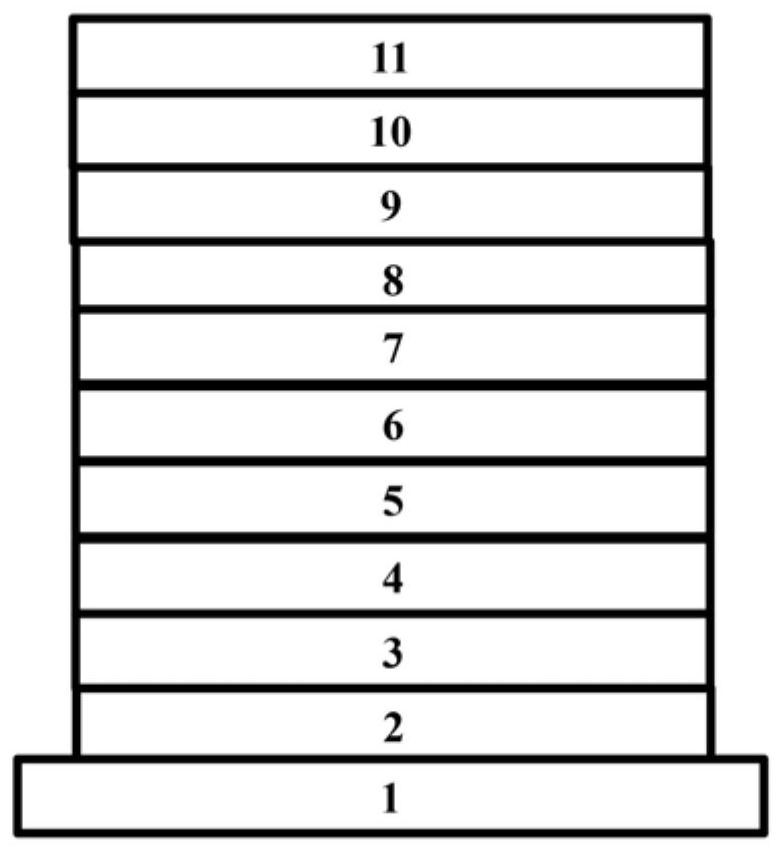

[0045] A fully fluorescent white OLEDs (W1) combined with TTA and phosphorescent sensitization, the schematic diagram of which is shown in figure 1 shown.

[0046] First, ultrasonically treat the ITO glass with alkaline washing solution, then rinse it with tap water, then rinse it with deionized water, blow dry the water on the surface of the ITO glass with high-pressure nitrogen, and then put the ITO glass in an oven to bake for 30 minutes , and then treat the surface of the ITO glass with ultraviolet ozone for 6 minutes, put it into the vacuum coating machine, when the pressure of the coating machine drops to 1×10 -4 When Pa is lower than that, thin films are sequentially deposited on ITO glass. First, the hole injection layer material HAT-CN is evaporated on the surface of the ITO conductive glass with a thickness of 15nm. Then, the hole transport layer material TAPC is sequentially evaporated, with a thickness of 60nm; the electron blocking layer material TCTA, with a th...

Embodiment 2

[0050] A fully fluorescent white OLEDs (W2) combined with TTA and phosphorescent sensitization, the schematic diagram of which is shown in Image 6 shown.

[0051] First, ultrasonically treat the ITO glass with alkaline washing solution, then rinse it with tap water, then rinse it with deionized water, blow dry the water on the surface of the ITO glass with high-pressure nitrogen, and then put the ITO glass in an oven to bake for 30 minutes , and then treat the surface of the ITO glass with ultraviolet ozone for 6 minutes, put it into the vacuum coating machine, when the pressure of the coating machine drops to 1×10 -4 When Pa is lower than that, thin films are sequentially deposited on ITO glass. First, the hole injection layer material HAT-CN is evaporated on the surface of the ITO conductive glass with a thickness of 15nm. Then, the hole transport layer material TAPC is sequentially evaporated, with a thickness of 60nm; the electron blocking layer material TCTA, with a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com