Metal roof structure with smoke exhaust function and edge holding-on welding method

A metal roof and functional technology, applied in the direction of roof, roof drainage, roof insulation materials, etc., can solve the problems of crack corrosion at the roof's thermal expansion and cold shrinkage, poor drainage capacity of roof gutters, and difficulty in roof construction, etc. , to achieve the effect of reducing construction difficulty and transportation difficulty, improving overall waterproofness and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

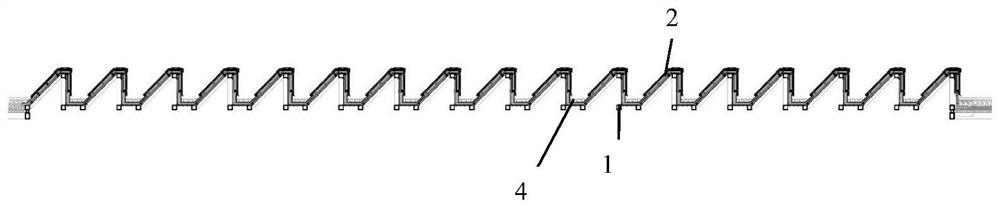

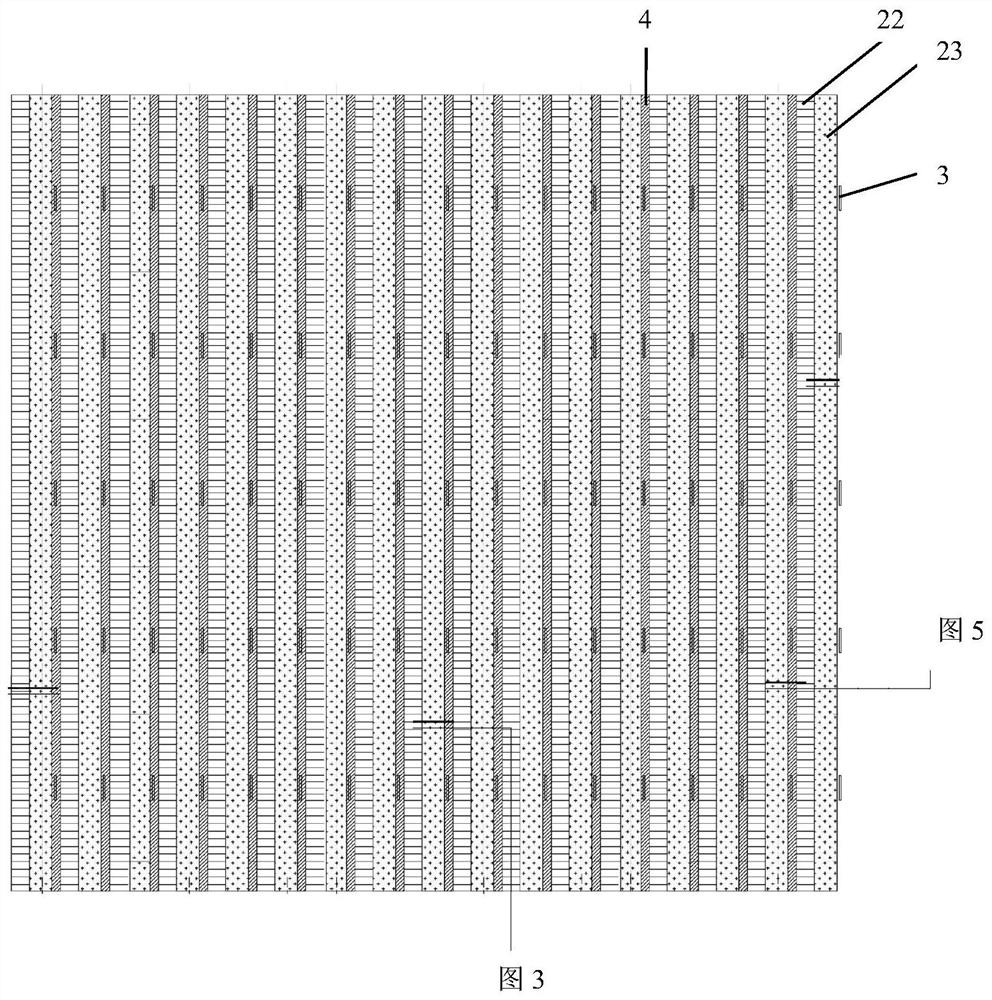

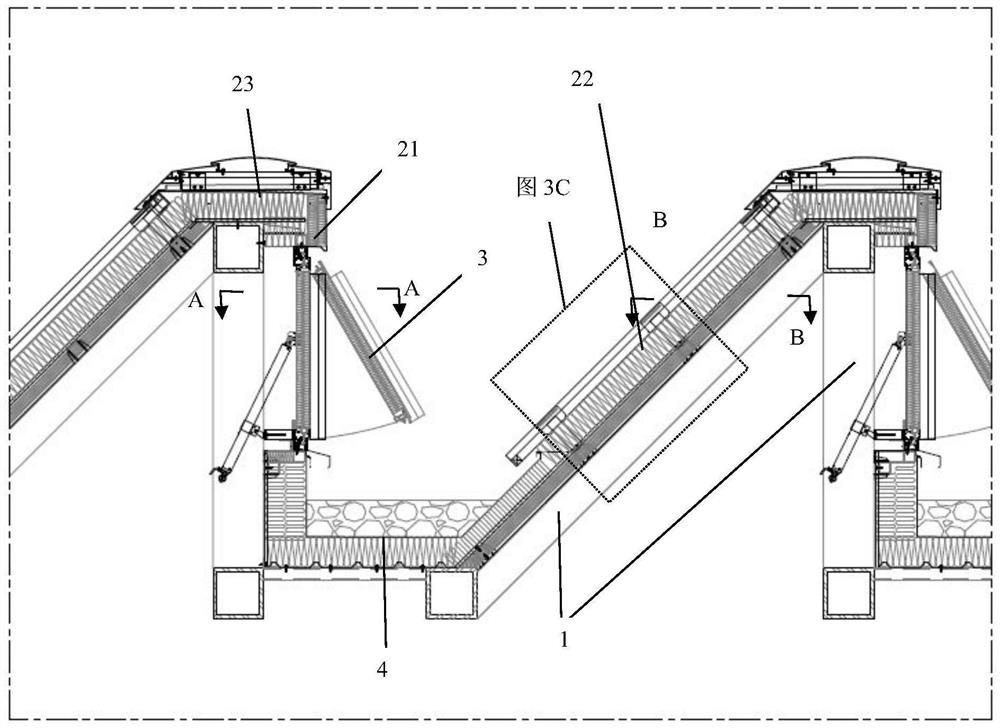

[0049] Please also refer to Figure 1 to Figure 5 Now, a metal roof structure with smoke exhaust function provided by the present invention will be described. This kind of metal roof structure with smoke exhaust function includes a sawtooth beam frame 1, a roof structure 2, a skylight 3 and a drainage ditch 4, wherein the sawtooth beam frame 1 is placed on the roof of the building and fixed on the building Above, the roof structure 2 is fixed on the top of the zigzag beam frame 1, the skylight 3 is installed and inlaid on the roof structure 2, and the drainage ditch 4 is fixed at the lower end of the zigzag beam frame 1 to connect the adjacent roof structure 2. The metal roof structure with smoke exhaust function has no gaps in the overall connection, and has good water and air tightness. Due to the installation of skylights on the roof structure, the roof has the function of smoke exhaust and ventilation. Multiple skylights 3 form air intake windows and air outlet windows. E...

Embodiment 2

[0052] As a specific implementation of the embodiments of the present invention, please refer to Figure 1 to Figure 5 , the metal roof structure with smoke exhaust function provided by this embodiment is basically the same as that of Embodiment 1, the difference is that the zigzag beam frame 1 is composed of a plurality of right-angled triangle beam frames, and the adjacent right-angled triangles The bottom ends of the beam frames are connected with beams; the roof facade structure layer 21 is arranged on the vertical surface of the right-angled triangular beam frame, and the roof facade structure layer 21 is provided with a skylight 3; the roof surface structure layer 22 is arranged on On the slope of the right-angled triangular beam frame; the roof ridge structure layer 23 is arranged on the top of the right-angled triangular beam frame for connecting the roof surface structure layer 22 and the roof façade structure layer 21 .

[0053] Specifically, the zigzag beam frame 1 ...

Embodiment 3

[0064] As a specific implementation of the embodiments of the present invention, please refer to Figure 1 to Figure 6 , the present invention also provides a metal roof surface seam welding construction process, characterized in that: the construction process includes the following steps:

[0065] S1: According to the requirements of the construction drawings, produce roof tiles 5 that meet the installation size, install zigzag beams 1, complete the main body installation, and perform horizontal and vertical verification;

[0066] S2: The steel plate 8 is laid on the zigzag beam frame 1, and the screws on the steel plate 8 are parallel to the purlin 9 in the direction of the roof ridge. direction, a noise reduction layer 11 is laid on the steel plate 8, and a supporting layer 12 and a waterproof layer 13 are laid on the noise reduction layer 11;

[0067] S3: Fix the first row of sliding combined brackets 28 on the sub-purlins 6 with screws and sealing rings, lay the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com