Modified barium sulfate weighting agent for ultrahigh-temperature water-based drilling fluid, preparation method thereof and ultrahigh-temperature water-based drilling fluid

A water-based drilling fluid, barium sulfate technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor suspension performance, and achieve the effects of stable performance, slowing down settling tendency, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The second aspect of the present invention provides a kind of preparation method of aforementioned modified barium sulfate weighting agent, wherein, described preparation method comprises the following steps:

[0043] (1) sulfate and barium salt are contacted in rich ammonia solvent to obtain barium sulfate;

[0044] (2) In the presence of an acid and a catalyst, the barium sulfate, biomass and solvent are subjected to a hydrothermal reaction to obtain a modified barium sulfate weighting agent.

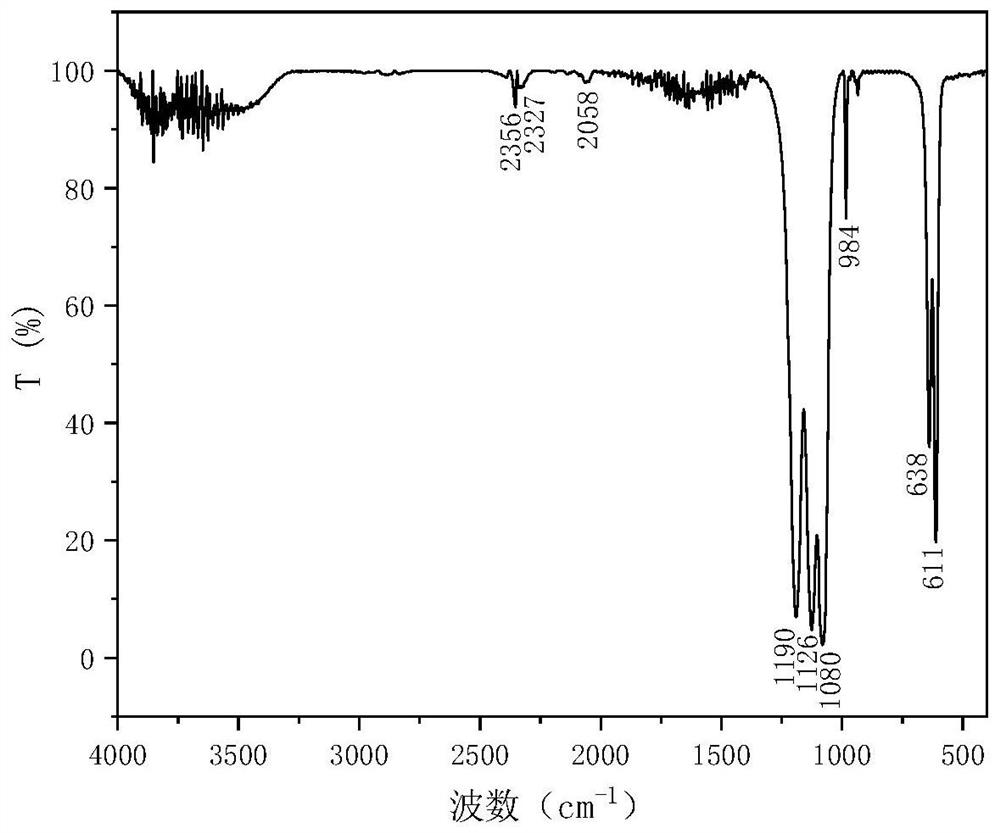

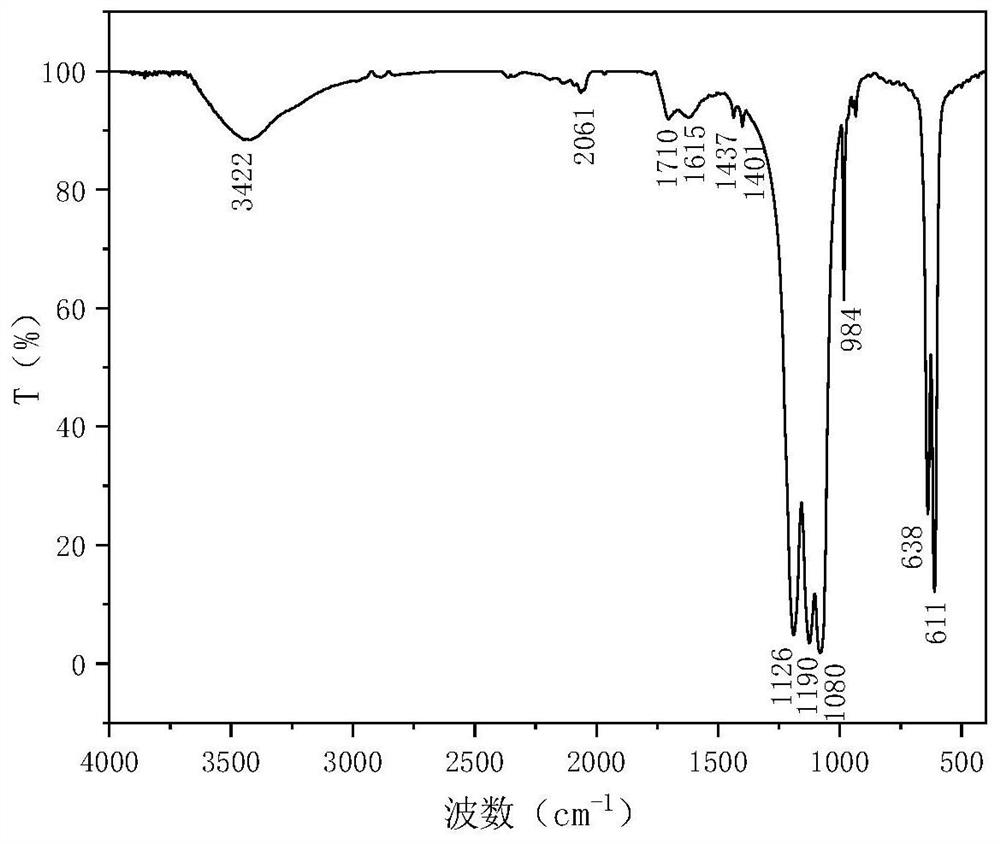

[0045] In the present invention, the surface of the modified barium sulfate weighting agent prepared by hydrothermal reaction is rich in oxygen-containing functional groups such as hydroxyl, carboxyl, and sulfonic acid groups, which can significantly improve the dispersion stability of the modified barium sulfate weighting agent at high temperature.

[0046] According to the present invention, in step (1), the sulfate is selected from one or more of sodium sulfate, ammonium sul...

Embodiment 1

[0087] This embodiment is to illustrate the modified barium sulfate weighting agent prepared by the method of the present invention.

[0088] (1) Take 30g of sodium sulfate, stir and dissolve it in 200mL of ammonia water (concentration is 20% by mass), and slowly add 288mL of 25% anhydrous barium chloride solution dropwise at a speed of 5mL / min by using a peristaltic pump to react Set the temperature at 10°C and stir at 5,000rpm for 40min; after the reaction, centrifuge the suspension at 10,000rpm for 20min to obtain an off-white precipitate, wash it with deionized water three times, and dry it at 80°C to obtain barium sulfate with an average particle size of 318.2nm .

[0089] (2) Weigh 30g of barium sulfate and disperse it into 300mL of deionized water at high speed. Add 100g glucose, 80g fructose, 18g citric acid, 9g FeCl 2 and spread it evenly. It was transferred to a polytetrafluoroethylene-lined hydrothermal reactor and placed in a roller furnace. Set the heating tem...

Embodiment 2

[0095] This embodiment is to illustrate the modified barium sulfate weighting agent prepared by the method of the present invention.

[0096] (1) Weigh 24g of sodium sulfate, stir and dissolve it in 200mL of ammonia water (concentration is 10% by mass), and slowly add 160mL of 25% anhydrous barium chloride solution dropwise at a speed of 7mL / min using a peristaltic pump to react Set the temperature at 10°C and stir at 4,000rpm for 30min; after the reaction, centrifuge the suspension at 10,000rpm for 20min to obtain an off-white precipitate, wash it with deionized water three times, and dry it at 80°C to obtain barium sulfate with an average particle size of 512.4nm .

[0097] (2) Weigh 20 g of barium sulfate and disperse it into 300 mL of deionized water at high speed. Add 20g lignin, 15.6g acrylic acid, 7.2g FeCl 3 and spread it evenly. It was transferred to a polytetrafluoroethylene-lined hydrothermal reactor and placed in a roller furnace. Set the heating temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com