Bactericidal emulsion pressure-sensitive adhesive, dust-sticking pad and preparation method of dust-sticking pad

A sterilizing milk and hydraulic technology, applied in adhesives, pressure-sensitive films/sheets, cleaning equipment, etc., can solve the problem of no bactericidal and antibacterial effects, achieve stable bactericidal and antibacterial effects, improve bactericidal effects, and good reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

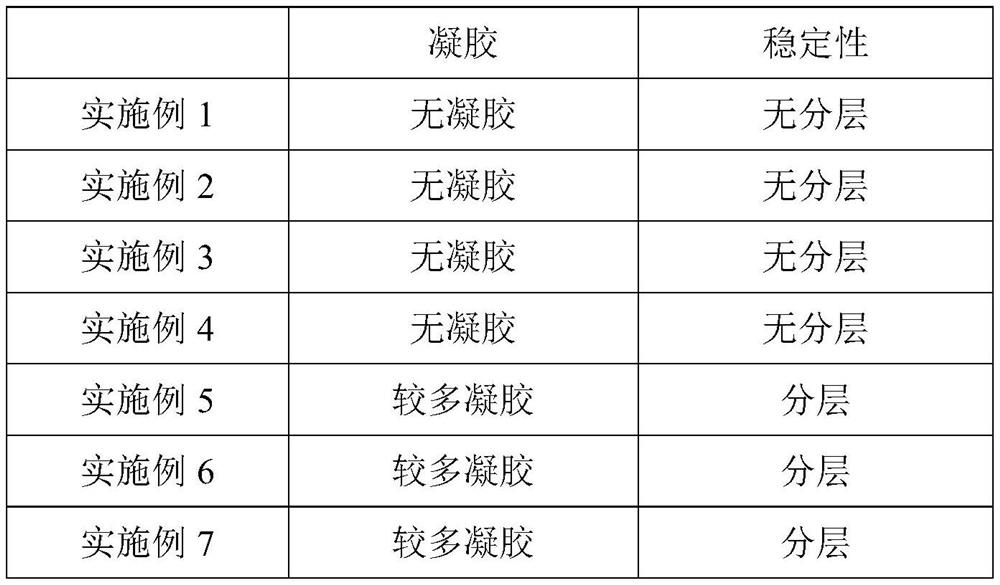

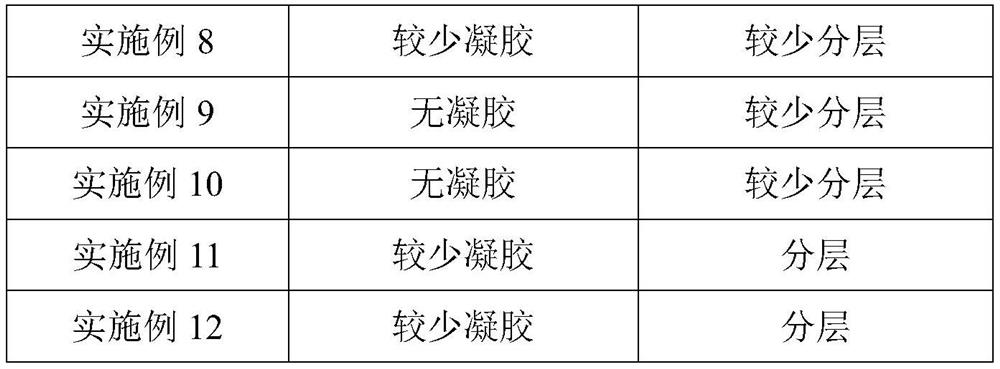

Examples

preparation example Construction

[0079] In one embodiment, the preparation method of the sterilizing emulsion pressure-sensitive adhesive comprises the steps:

[0080] (1) uniformly mixing acrylate monomer, N methylol acrylamide, molecular weight regulator, surfactant and deionized water to obtain emulsion;

[0081] (2) heating the reactor to 80°C, taking 6wt% of the emulsion described in step (1) and adding it to the reactor, then adding an initiator, polymerizing for half an hour as a seed, then adding the remaining step (1) described The emulsification is added dropwise to the reaction kettle for 4 hours, the temperature is kept for 1 hour, and the temperature is lowered to 45 ° C. The treatment agent is added, stirred, and then glacial acetic acid is added to adjust the pH to 5-6. The bactericidal emulsion pressure-sensitive adhesive.

[0082] A second aspect of the present invention provides a sticky dust pad containing the above-mentioned sterilizing emulsion pressure-sensitive adhesive.

[0083] A th...

Embodiment 1

[0104] Embodiment 1 provides a kind of sterilizing emulsion pressure-sensitive adhesive, in parts by weight, the components of the sterilizing emulsion pressure-sensitive adhesive are: 900 parts of acrylate monomers, 0.5 parts of molecular weight regulator, 20 parts of surfactant, 0.02 parts of initiator, 2 parts of N-methylol acrylamide, 6 parts of treatment agent, 1200 parts of deionized water;

[0105] The acrylate monomer is a mixture of hydroxyethyl acrylate, dimethylaminoethyl methacrylate, glycidyl methacrylate, methyl methacrylate, isooctyl acrylate, and butyl acrylate; The mass ratio of ethyl ester, dimethylaminoethyl methacrylate, glycidyl methacrylate, methyl methacrylate, isooctyl acrylate and butyl acrylate is 1.5:2:1:5:65:15;

[0106] Described molecular weight regulator is n-dodecyl mercaptan;

[0107] The surfactant is a mixture of quaternary ammonium salt surfactant 1227 and AEO-9; the mass ratio of the quaternary ammonium salt surfactant 1227 and AEO-9 is 2....

Embodiment 2

[0121] Embodiment 2 provides a kind of sterilizing emulsion pressure-sensitive adhesive, in parts by weight, the components of the sterilizing emulsion pressure-sensitive adhesive are: 1000 parts of acrylate monomers, 1 part of molecular weight regulator, 40 parts of surfactant, 0.04 parts of initiator, 4 parts of N-methylol acrylamide, 10 parts of treatment agent, 1400 parts of deionized water;

[0122] The acrylate monomers are the same as those in Example 1, except that the hydroxyethyl acrylate, dimethylaminoethyl methacrylate, glycidyl methacrylate, methyl methacrylate, and isooctyl acrylate are different. , The mass ratio of butyl acrylate is 2.5:3:1:8:75:25;

[0123] Described molecular weight regulator is n-dodecyl mercaptan;

[0124]The surfactant is the same as in Example 1, except that the mass ratio of the quaternary ammonium salt surfactant 1227 and AEO-9 is 2.5:1;

[0125] The initiator is dimethyl azobisisobutyrate;

[0126] The treatment agent is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com