A kind of composite functional additive and its preparation method and application in propellant

A technology of functional additives and propellants, used in non-explosive fillers/gelling agents/thickeners, offensive equipment, explosives processing equipment, etc. The effect of reducing electrostatic spark sensitivity and electrostatic spark sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046]A preparation method of a combined functional auxiliary, the steps are: dissolving CAB in acetone (dissolving in a mass ratio of 1:40) to prepare a solution, then adding BA to stir and dissolve to form a suspension to obtain a combined functional auxiliary.

[0047] A propellant containing a combination of functional additives, the propellant includes a binder system, an oxidizing agent, a metal fuel, a curing agent, a combined functional additive and other additives;

[0048] Taking the total mass of the propellant as 100%, the mass percentage of each component is:

[0049] Adhesive system 17%~25%

[0050] Oxidant 52%~65%

[0051] Metal fuel 15%~20%

[0052] Curing agent 0.5%~0.9%

[0053] Combination of functional additives 0.5% to 2%

[0054] Other additives 0.6%-0.85%

[0055] The adhesive system includes an adhesive and a plasticizer, wherein the adhesive is hydroxyl-terminated oxirane-tetrahydrofuran copolyether PET, polyethylene glycol PEG or polyazide glycid...

Embodiment 1

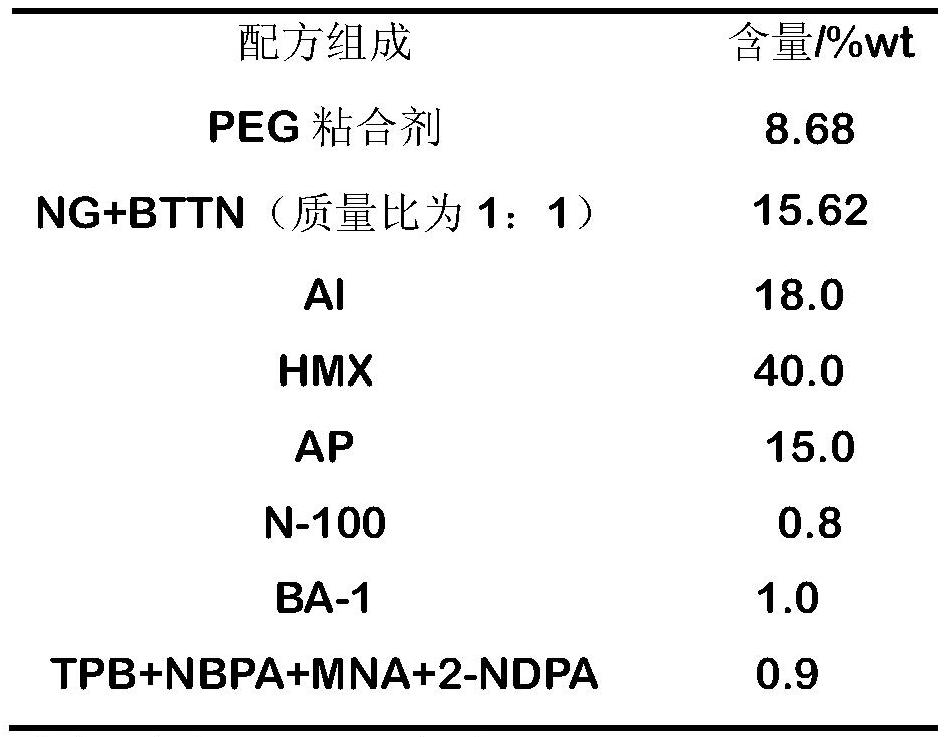

[0070] Propellant composition (based on the total mass of propellant as 100%, mass percent content)

[0071]

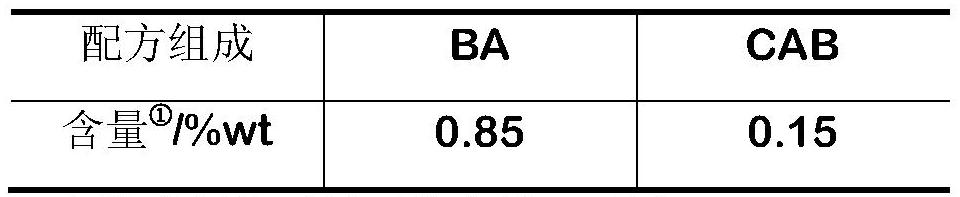

[0072] Wherein the above-mentioned combined functional auxiliary agent BA-1 comprises:

[0073]

[0074] Note ①: Percentage of total propellant mass, the same below.

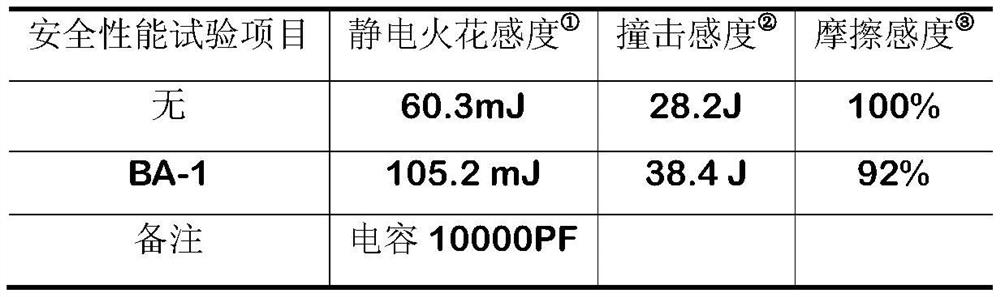

[0075] The safety test results of the high-energy propellant billet prepared by adding BA-1 are shown in Table 1. It can be seen that compared with the blank, the electrostatic spark sensitivity of the propellant added with BA-1 is significantly reduced.

[0076] Table 1 Safety test results

[0077]

[0078] Note: The sensitivity of the propellant to the external stimulus is expressed by sensitivity. The greater the sensitivity, the more sensitive it is to the outside world, and it is easier to detonate. ①Indicates the static spark energy of 50% explosion under the excitation of static spark, the smaller the value, the higher the sensitivity. ② Indicates 50% of the critical impact energy. ...

Embodiment 2

[0083] Propellant composition (mass percent)

[0084]

[0085] Wherein the above-mentioned combined functional auxiliary agent BA-2 comprises:

[0086]

[0087] The electrostatic spark sensitivity of the high-energy propellant containing the above combined functional additives (BA-2 for short) is 138.3J, the impact sensitivity is 39.1J, and the friction sensitivity is 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact sensitivity | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com