Advanced treatment method of garbage permeate fluid

A garbage permeate and advanced treatment technology, which is applied in the field of multi-stage treatment of water, wastewater or sewage, can solve the problems of equipment scaling, short service life, C/N ratio imbalance, etc., to overcome serious blockage and long service life Long, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

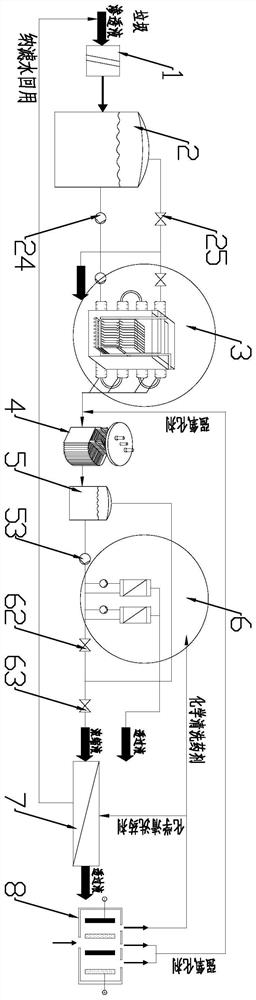

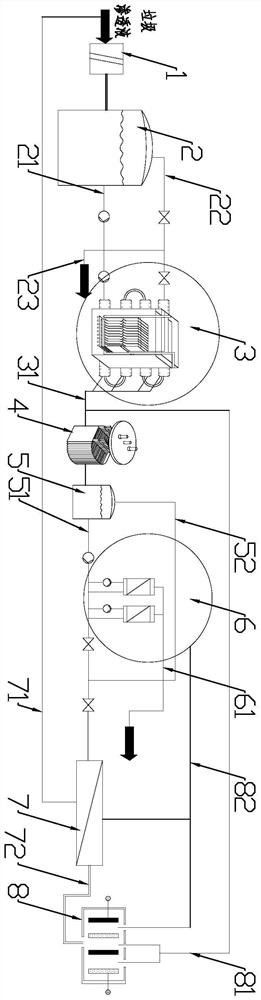

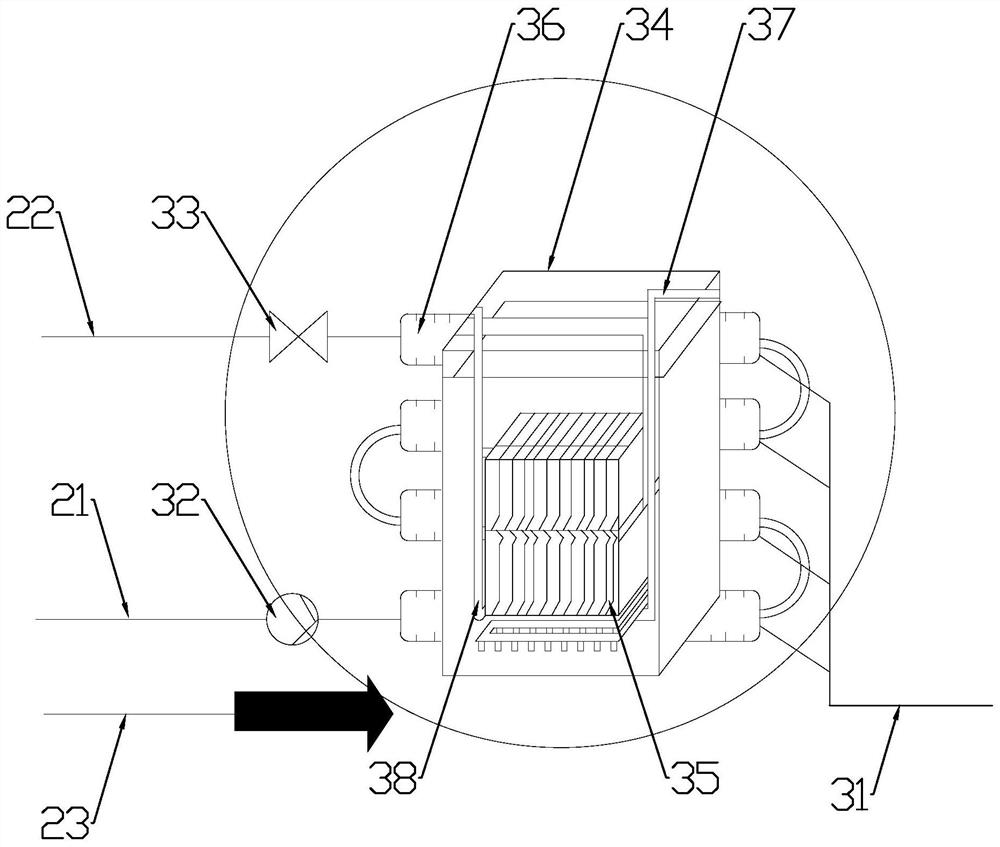

[0056] In the landfill leachate treatment method of this embodiment, the waste leachate to be treated is sequentially discharged through external ceramic MBR membrane filtration, electrolytic flocculation precipitation, single-stage DTRO, nanofiltration, and bipolar electrolysis. The external ceramic MBR 3 It includes a casing 34 and a membrane separation assembly 35 arranged in the casing 34. The membrane separation assembly 35 is connected with an aeration pipe 1 37 and an aeration pipe 2 38. The garbage permeate is input through the centrifugal liquid pump 1 24, and the membrane separation assembly After the aeration reaction in 35 is completed, it is input to the electrolytic flocculation mechanism 4 to complete the electrolytic flocculation and sedimentation, and the sediment supernatant is pumped into the single-stage DTRO 6 through the centrifugal liquid pump 3 53, and the single-stage DTRO 6 includes the membrane module 1 64 and the membrane Module 2 65, after membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com