Wear-resistant scratch-resistant antibacterial BOPET film and preparation method thereof

An anti-scratch and film technology, applied in the field of plastic film manufacturing, can solve the problems of low hardness of BOPET film, poor scratching of PET film, inapplicability of anti-scratch, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

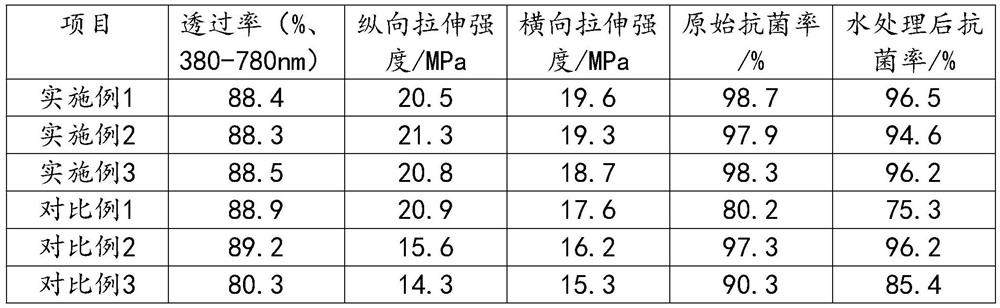

Examples

Embodiment 1

[0034] A wear-resistant, scratch-resistant and antibacterial BOPET film composed of A surface layer, B core layer and C bottom layer. The A surface layer and the C bottom layer are located on both sides of the B core layer. The A surface layer is an antibacterial layer, and the B core layer is a filling layer , C bottom layer is abrasion and scratch resistance layer;

[0035] The A surface layer includes the following raw materials: 96% of PET chips, 4.0% of composite antibacterial agent, 0.001% of catalyst and 0.003% of stabilizer according to mass percentage;

[0036] The B core layer is PCTG copolyester chip;

[0037] The C bottom layer includes the following raw materials: 96% of PET chips, 1.5% of toughening agent, 1.0% of KH550 silane coupling agent, 1.5% of functional additives, 0.001% of catalyst, and 0.003% of stabilizer by mass percentage.

[0038] The wear-resistant, scratch-resistant and antibacterial BOPET film has a thickness of 20 μm, and the thickness ratio of the A su...

Embodiment 2

[0057] A wear-resistant, scratch-resistant and antibacterial BOPET film composed of A surface layer, B core layer and C bottom layer. The A surface layer and the C bottom layer are located on both sides of the B core layer. The A surface layer is an antibacterial layer, and the B core layer is a filling layer , C bottom layer is abrasion and scratch resistance layer;

[0058] The A surface layer includes the following raw materials: 96% of PET chips, 4.0% of composite antibacterial agent, 0.001% of catalyst and 0.003% of stabilizer according to mass percentage;

[0059] The B core layer is PCTG copolyester chip;

[0060] The C bottom layer includes the following raw materials: 96% of PET chips, 1.5% of toughening agent, 1.0% of KH550 silane coupling agent, 1.5% of functional additives, 0.001% of catalyst, and 0.003% of stabilizer by mass percentage.

[0061] The wear-resistant, scratch-resistant and antibacterial BOPET film has a thickness of 40 μm, and the thickness ratio of the A su...

Embodiment 3

[0080] A wear-resistant, scratch-resistant and antibacterial BOPET film composed of A surface layer, B core layer and C bottom layer. The A surface layer and the C bottom layer are located on both sides of the B core layer. The A surface layer is an antibacterial layer, and the B core layer is a filling layer , C bottom layer is abrasion and scratch resistance layer;

[0081] The A surface layer includes the following raw materials: 96% of PET chips, 4.0% of composite antibacterial agent, 0.001% of catalyst and 0.003% of stabilizer according to mass percentage;

[0082] The B core layer is PCTG copolyester chip;

[0083] The C bottom layer includes the following raw materials: 96% of PET chips, 1.5% of toughening agent, 1.0% of KH550 silane coupling agent, 1.5% of functional additives, 0.001% of catalyst, and 0.003% of stabilizer by mass percentage.

[0084] The wear-resistant, scratch-resistant and antibacterial BOPET film has a thickness of 40 μm, and the thickness ratio of the A su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com