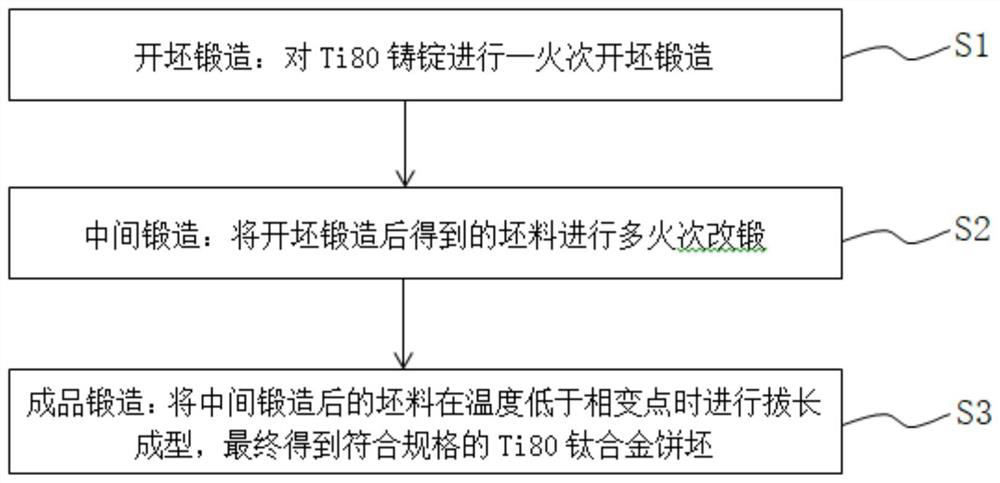

Forging method of super-large-specification Ti80 titanium alloy forging stock

A super-sized, titanium alloy technology, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problem of uneven deformation at the end and middle, so as to avoid uneven deformation, broad application prospects, Guarantee the effect of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

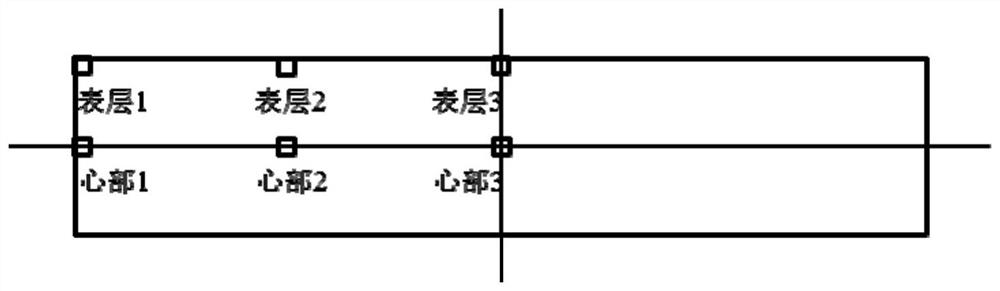

Examples

Embodiment 1

[0034] Example 1, forging an ingot with a diameter of 1020mm and a weight of 11T:

[0035] S1. Billet forging: the heating temperature of ingot forging is 1150°C, and it is heated for 20 hours before being out of the furnace. The ingot is subjected to an upsetting deformation with an anvil tool with a diameter of 1800mm. The ratio is 1.2, and it is cooled by air cooling after forging. Among them, using an anvil with a diameter of 1800mm to carry out an upsetting deformation can ensure the overall plastic deformation of the ingot, avoiding the phenomenon that the ingot has an excessively large height-to-diameter ratio, and the phenomenon of uneven deformation at the end and middle during upsetting, which is reversed. Edge treatment avoids deformation dead zone at edges and corners;

[0036] S2. Intermediate forging: the ingot after the blank forging in step S1 is re-forged in the single-phase zone for 7 fires, and the heating temperature for each fire is selected to be 20°C to...

Embodiment 2

[0043] Embodiment 2, forging an ingot with a diameter of 1020mm and a weight of 11T:

[0044] S1. Billet opening and forging: the heating temperature of the ingot forging is selected at 1200°C, and it is heated for 22 hours before it is released from the furnace. The ingot is subjected to an upsetting deformation with an anvil tool with a diameter of 1800 mm. The ratio is 1.7, and it is cooled by air cooling after forging.

[0045] S2. Intermediate forging: the ingot after forging in step S1 is re-forged in the single-phase zone for 8 fire times, and the heating temperature for each fire is selected to be 20°C to 120°C above the phase transition point, and the heating temperature for each fire is Gradually decrease. Before each fire forging, the billet is wrapped with thick asbestos with a thickness of 25mm. After the material is out of the furnace, it is sequentially subjected to upsetting, elongation, and chamfering treatment. The forging ratio of each fire is 1.9. Air cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com