Acrylic resin powder, resin composition, hot melt adhesive composition containing acrylic resin powder and method for producing same

A technology of acrylic resin and resin composition, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc., can solve the problem of insufficient opening time of hot melt adhesives, etc., and achieve good initial bonding strength, long-term The effect of opening hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0219] Acrylic resin powder (P-1)

[0220] [Process Ⅰ(1)]

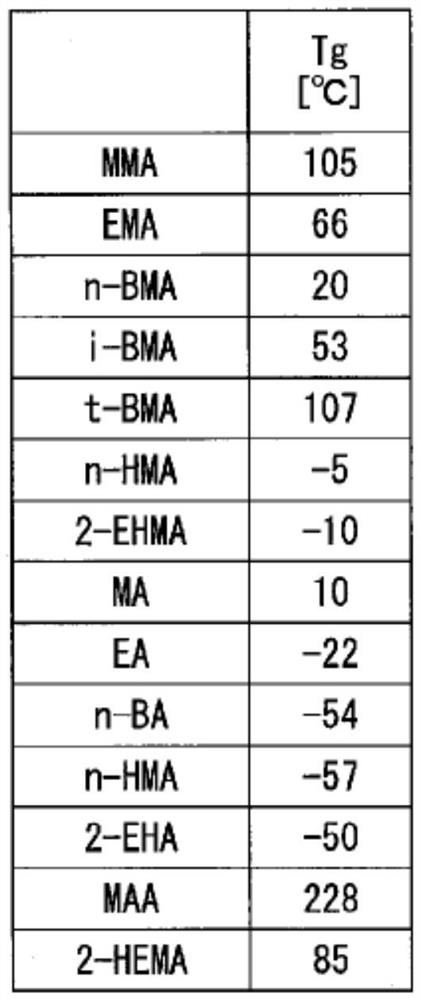

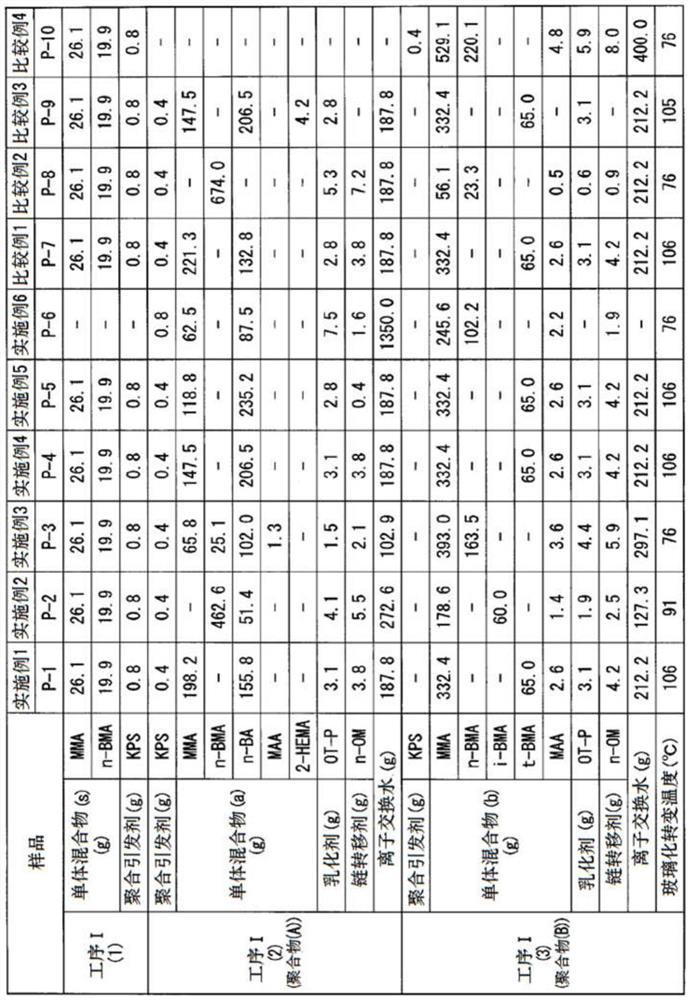

[0221] Into a 2-liter 4-neck flask equipped with a thermometer, a nitrogen gas introduction tube, a stirring rod, a dropping funnel, and a condenser tube, 583 g of ion-exchanged water was added, and nitrogen gas was introduced for 30 minutes to replace the dissolved oxygen in the ion-exchanged water. Next, the blowing of nitrogen gas was stopped, and the temperature was raised to 80° C. while stirring at 200 rpm. When the internal temperature reached 80°C, a monomer mixture (s-1) consisting of 26.1 g of methyl methacrylate and 19.9 g of n-butyl methacrylate was added together, and 0.80 g of potassium persulfate and ion 20 g of water was exchanged and kept for 45 minutes to obtain a polymer dispersion (S-1).

[0222] [Process I (2)]

[0223] To the polymer dispersion (S-1) obtained in [Step I (1)], 0.32 g of PELEX OT-P (disodium dioctyl sulfosuccinate, 70% active ingredient, manufactured by Kao Corporation) was add...

Embodiment 2

[0229] Acrylic resin powder (P-2)

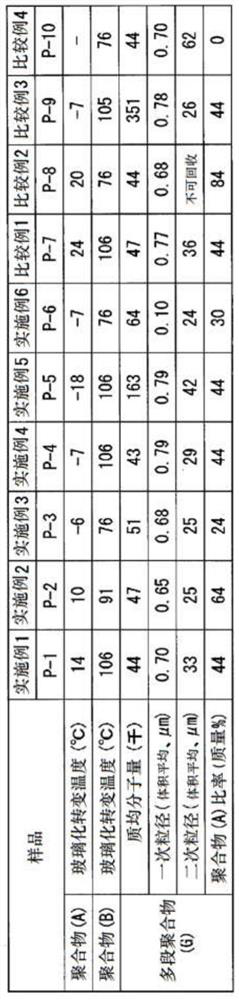

[0230] An acrylic resin powder (P-2) was produced in the same manner as in Example 1 except that the monomer mixtures (a) and (b) had the mass shown in Table 2. The results are shown in Table 3.

Embodiment 3

[0231] Acrylic resin powder (P-3)

[0232] An acrylic resin powder (P-3) was produced in the same manner as in Example 1 except that the monomer mixtures (a) and (b) had the mass shown in Table 2. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com