Method for preparing bonded product by single-sided gluing

A product, single-sided technology, applied in the field of adhesive products prepared by gluing on one side, to achieve good initial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

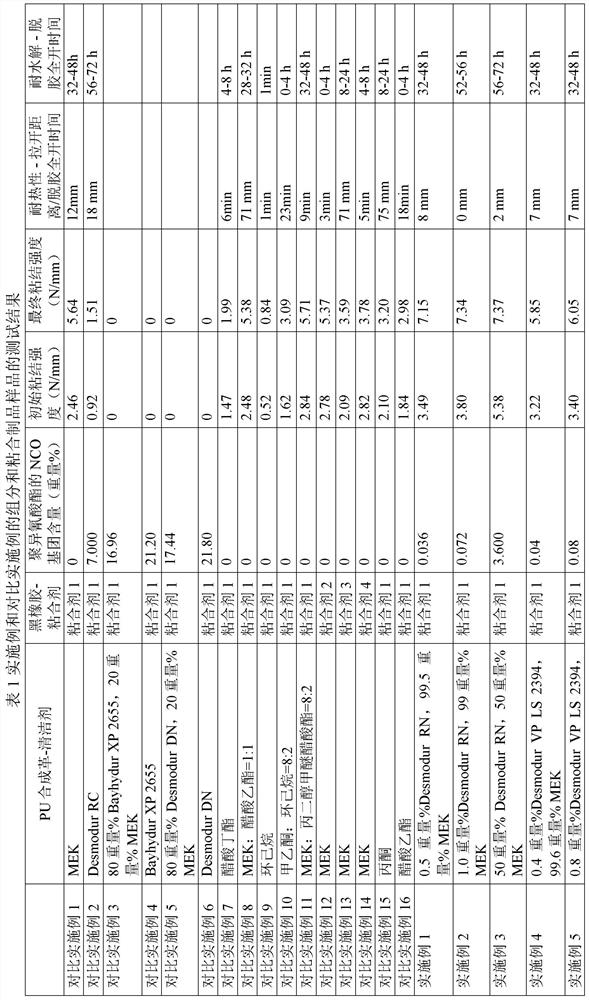

Examples

Embodiment Construction

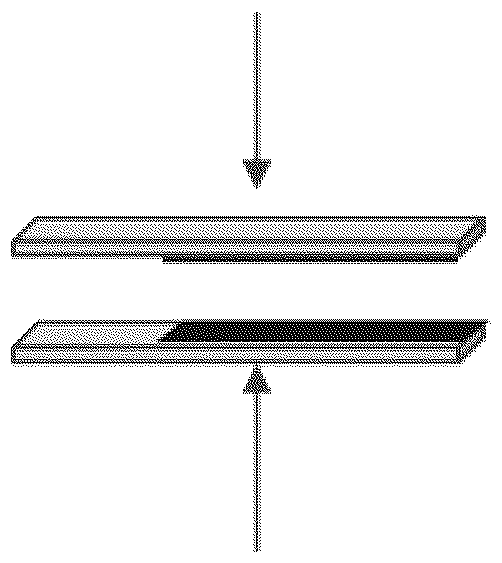

[0017] The present invention provides a method for preparing a bonded article with one-sided gluing, comprising the following steps: a. applying a cleaning agent to at least one surface of a first substrate, and drying the surface of the first substrate on which the cleaning agent is applied b. applying an adhesive to at least one surface of a second substrate, drying the second substrate surface to which the adhesive is applied; and c. making the first substrate surface treated in step a Contacting the surface of the second substrate treated in step b to obtain the bonded product; wherein the polar organic solvent has a boiling point not higher than 135° C. and isocyanate non-reactive; the polyisocyanate conforms to the general formula R(NCO ) n , wherein, R is one or more of the following: aliphatic hydrocarbon groups containing 2-18 carbon atoms, aromatic hydrocarbon groups containing 6-15 carbon atoms and araliphatic hydrocarbon groups containing 8-15 carbon atoms, n Not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com