Modular heat preservation shell structure

A technology of thermal insulation shell and thermal insulation tube shell, which is applied in the directions of thermal insulation, pipeline protection, and pipeline protection through thermal insulation, etc., can solve the problems of collapse and accumulation of pipeline thermal insulation materials, uneven bulk density, etc. Uniform, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

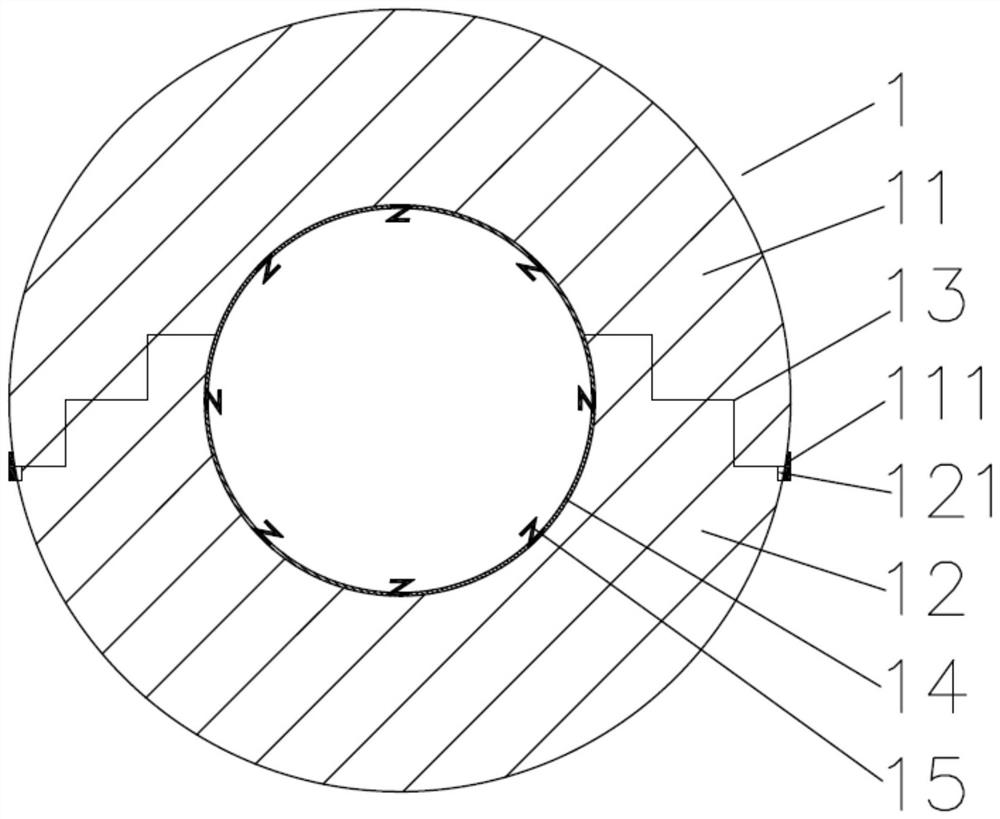

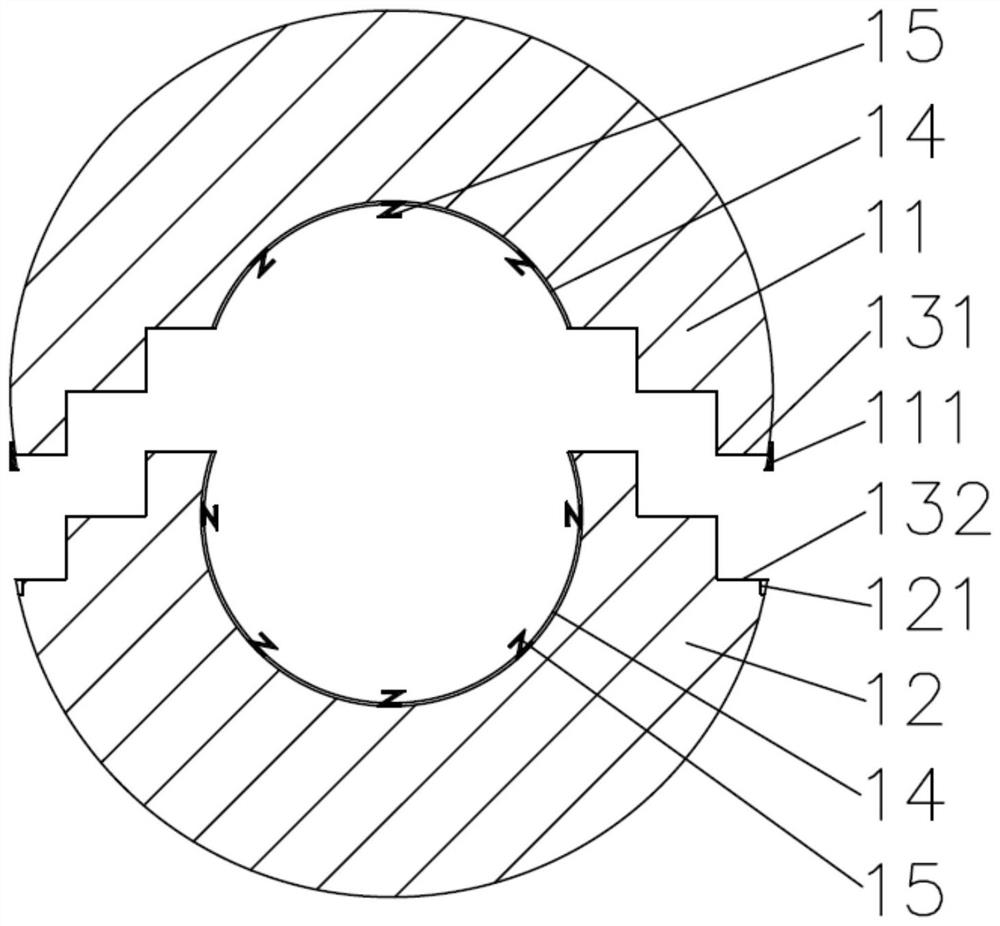

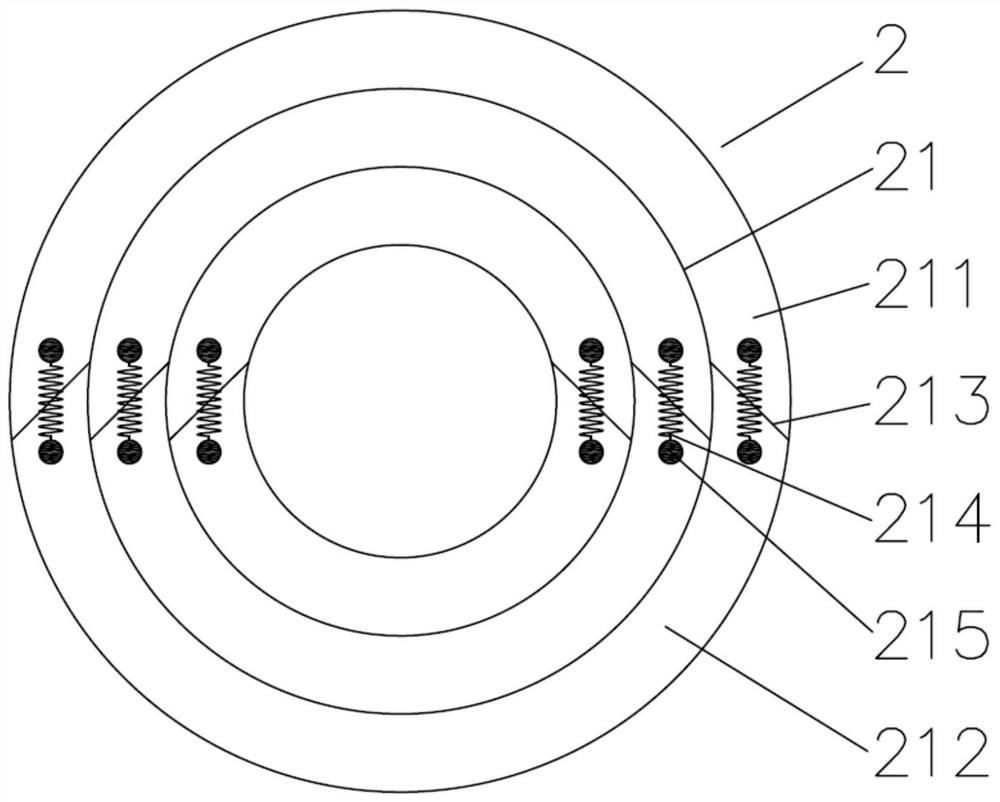

[0032] Such as Figure 1~4 As shown, a modular thermal insulation shell structure is characterized in that it includes a rigid thermal insulation tube shell 1 and a flexible thermal insulation tube shell 2; the rigid thermal insulation tube shell 1 is a hollow cylindrical structure with internal detachable connecting pipes, and the rigid thermal insulation tube shell 1 It includes a first half-shell 11 and a second half-shell 12, the joint of the first half-shell 11 and the second half-shell 12 is a three-stage stepped shape 13 and the outermost side of the first half-shell 11 is convex The outermost side of the step 131 and the second half-shell 12 corresponds to the groove 132; the inner wall of the rigid heat-insulating tube shell 1 is provided with a fixing belt 14 which is annular and the fixing belt 14 and the inner wall of the rigid heat-insulating tube shell 1 are integrally formed Structure; the Z-shaped elastic liner 15 is fixedly connected to the fixing belt 14, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com