Gas production device of high-gas-content well

A technology for gas production and gas wells, which is applied in the field of gas production devices and wellhead devices for high gas content wells, and can solve problems such as idle resources, lower temperature of produced fluid, and easy freezing of nozzle sleeves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

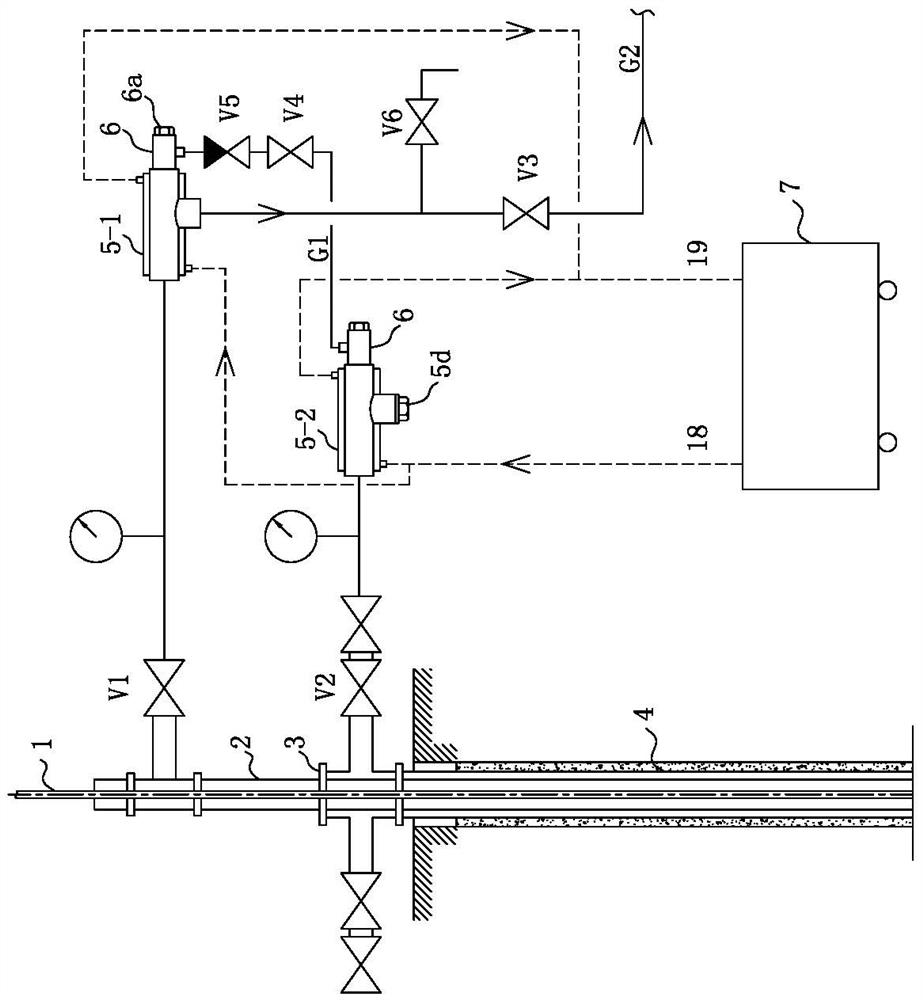

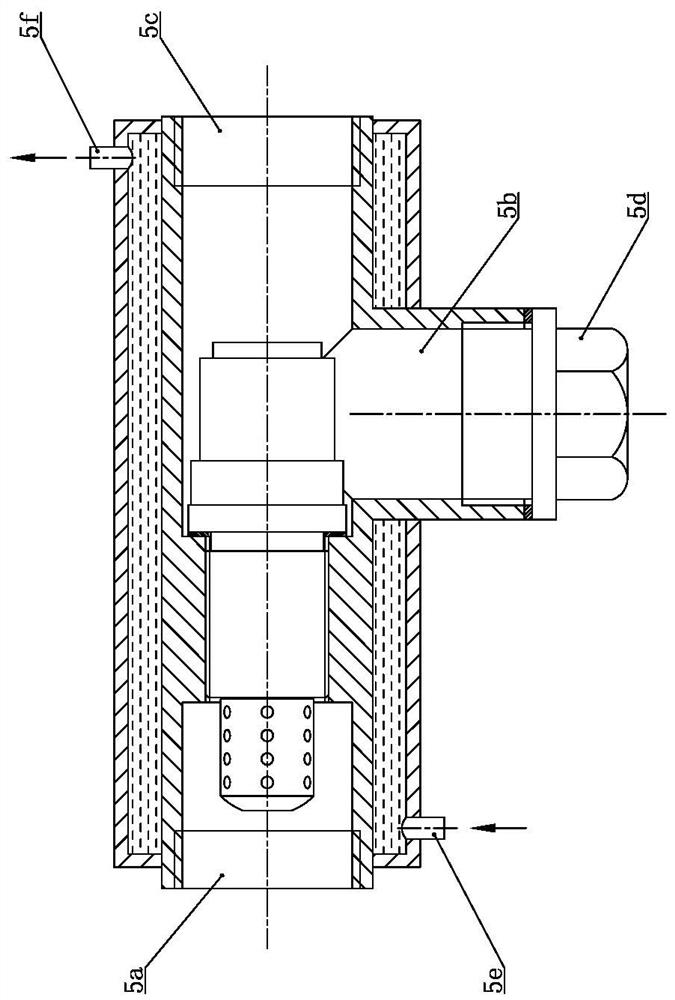

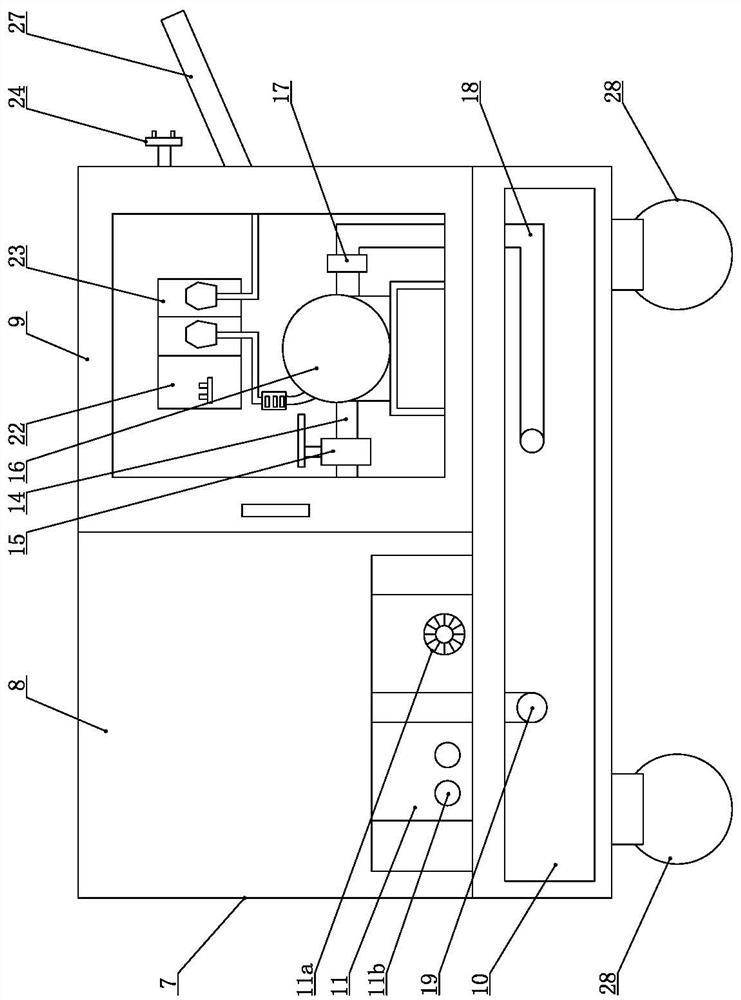

[0033] Such as figure 1 , figure 2 As shown, in the gas production device of the high gas content well of the present invention, the sucker rod 1 extends downhole along the oil pipe 2 from top to bottom, the oil pipe 2 is located in the downhole casing 4, and the upper port of the downhole casing 4 is installed with a The above wellhead spool 3, the upper end of the tubing 2 passes through the center of the wellhead spool 3, the left and right sides of the wellhead spool 3 are respectively connected with the casing gate V2 communicating with the downhole casing annulus, the upper part of the tubing 2 One side is connected with the production gate V1, the outlet of the production gate V1 is connected with the high-pressure inlet 5a of the nozzle sleeve 1 5-1, and the middle low-pressure outlet 5b of the nozzle sleeve 5-1 is connected to the underground gathering and transportation main pipe G2 through the back pressure valve V3 Connected; the upstream of the back pressure val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com