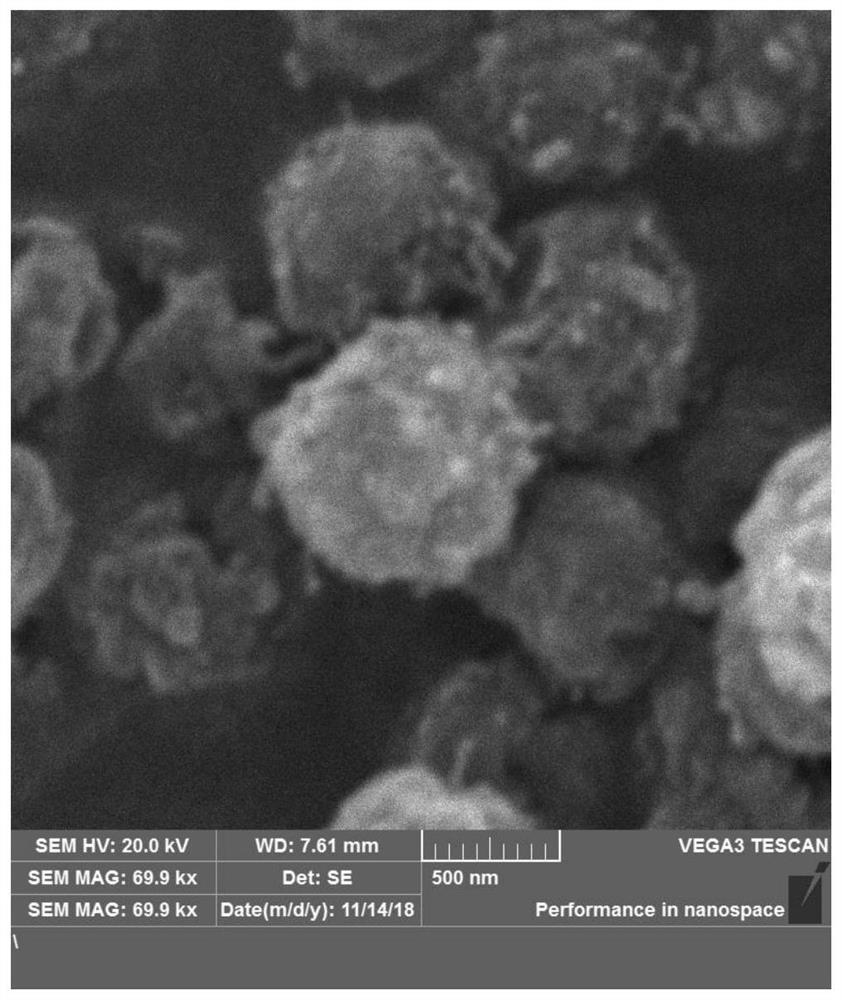

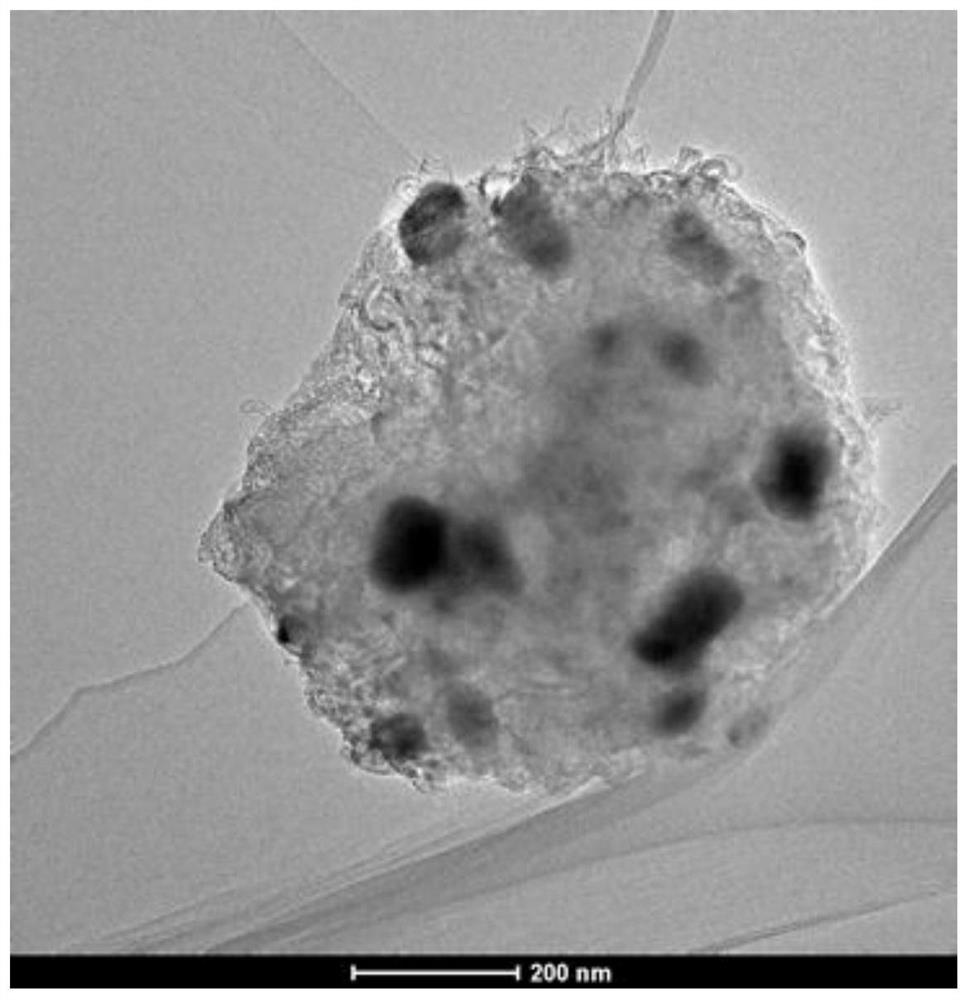

Composite hollow nanosphere of MXene and carbon nanotube as well as autocatalytic preparation method and application thereof

A hollow nano, carbon nanotube technology, applied in chemical instruments and methods, carbide, titanium carbide, etc., can solve the problems of easy agglomeration and difficult dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method for preparing MXene-CNT hollow nanospheres by self-catalysis comprises the following steps:

[0029] (1) Add 2g of melamine and 2mL of formaldehyde into 100mL of water, heat up to 80°C, after the solution is clarified, add 0.54g of PVA, and then add 0.21g of citric acid after the PVA is completely dissolved, react for 10min, and perform 3 times of washing-centrifugation After the process (3000rpm, 5min each time), collect the lower precipitate and dry to obtain MF microsphere powder;

[0030] (2) Add 20 mL of HCl with a concentration of 9 mol / L and 1 g of LiF into the beaker, and turn on the stirring device. Then slowly add 2g Ti while stirring 3 AlC 2 , After the addition was complete, it was stirred at room temperature for 108 h to obtain the MXene phase. Ultrasonic stripping, followed by repeated washing-centrifugation process, until the pH value of the solution is equal to 6, then centrifuged at 4500rpm, the supernatant is collected, filtered, and drie...

Embodiment 2

[0035] The method for preparing MXene-CNT hollow nanospheres by self-catalysis comprises the following steps:

[0036] (1) Add 2g of melamine and 2mL of formaldehyde into 100mL of water, heat up to 80°C, after the solution is clarified, add 0.54g of PVA, and then add 0.21g of citric acid after the PVA is completely dissolved, react for 10min, and perform 3 times of washing-centrifugation After the process (3000rpm, 5min each time), collect the lower precipitate and dry to obtain MF microsphere powder;

[0037] (2) Add 20 mL of HCl with a concentration of 9 mol / L and 2 g of LiF into the beaker, and turn on the stirring device. Then slowly add 1g Ti while stirring 3 AlC 2 , After the addition was complete, it was stirred at room temperature for 108 h to obtain the MXene phase. Ultrasonic stripping, followed by repeated washing-centrifugation process, until the pH value of the solution is equal to 6, then centrifuged at 4500rpm, the supernatant is collected, filtered, and drie...

Embodiment 3

[0042] The method for preparing MXene-CNT hollow nanospheres by self-catalysis comprises the following steps:

[0043] (1) Add 2g of melamine and 2mL of formaldehyde into 100mL of water, heat up to 80°C, after the solution is clarified, add 0.54g of PVA, and then add 0.21g of citric acid after the PVA is completely dissolved, react for 10min, and perform 3 times of washing-centrifugation After the process (3000rpm, 5min each time), collect the lower precipitate and dry to obtain MF microsphere powder;

[0044] (2) Add 20 mL of HCl with a concentration of 9 mol / L and 1 g of LiF into the beaker, and turn on the stirring device. Then slowly add 2g Ti while stirring 3 AlC 2 , After the addition was complete, it was stirred at room temperature for 108 h to obtain the MXene phase. Ultrasonic stripping, followed by repeated washing-centrifugation process, until the pH value of the solution is equal to 6, then centrifuged at 4500rpm, the supernatant is collected, filtered, and drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com