Synthesis device of 4-chloroacetoacetate

A chloroacetoacetate and synthesis device technology, applied in the chemical industry, can solve the problems of difficult control of chlorination depth, long reaction time, low product yield, etc., achieve long moving distance, many bubbles, and shorten reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The present invention also provides a kind of preparation method of 4-chloroacetoacetate, and specific technical scheme comprises:

[0094] 1) Diketene and organic solvent are mixed in a molar ratio of 0.5-50:1 to form a solution, and the above solution enters the first cavity of the reactor through the first feed pipe.

[0095] 2) Feed in chlorine gas, which enters the second cavity in the first material storage through the second feeding pipe, and enters the first cavity in the reactor through the first through hole, and the chlorine gas is introduced for 30 minutes.

[0096]3) Pass in ethanol, ethanol enters the third chamber in the second material storage through the third feed pipe, enters the first chamber in the reactor from the first through hole through the second through hole and the branch pipe, and the ethanol enters The time is 30 minutes.

[0097] 4) Discharge the above-mentioned reaction liquid through the discharge pipe, first perform fractional distill...

Embodiment 1

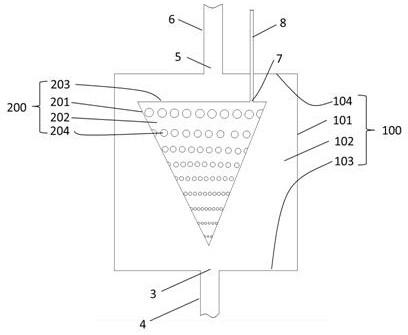

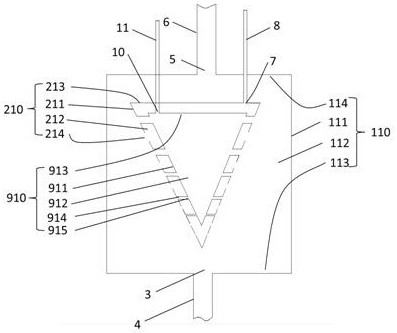

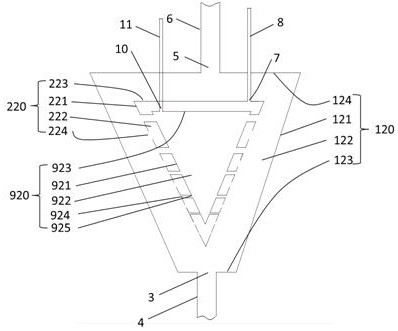

[0102] Such as image 3 The device for synthesizing 4-chloroacetoacetate shown includes a reactor 120 and a first material storage 220 disposed inside the reactor.

[0103] Wherein the reactor 120 comprises a first side wall 121, a first end wall 123, a second end wall 124 and a first cavity 122, and the first cavity 122 consists of the first side wall 121, the first end wall 123 and the second end wall. The wall 124 surrounds it; wherein the first end wall 123 is provided with a first feed port 3, and the first feed port 3 is provided with a first feed pipe 4, so that the first feed pipe 4 and the first cavity 122 ; the second end wall 124 is provided with a discharge port 5 , and a discharge pipe 6 is provided on the discharge port 5 , so that the discharge pipe 6 communicates with the first cavity 122 .

[0104] The first material storage 220 is arranged in the first cavity 122 of the reactor 120, including a second side wall 221, a third end wall 223 and a second cavity 2...

Embodiment 2

[0114] Except that the diameter of the first through hole 224 of the first material storage 220 is set along the axial direction of the first material storage 220 from the tapered large-diameter end to the small-diameter end, the geometric sequence is set in descending order, and the common ratio of the geometric sequence is 1.5, other The conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com