Method for efficiently extracting caffeine in coffee deep processing

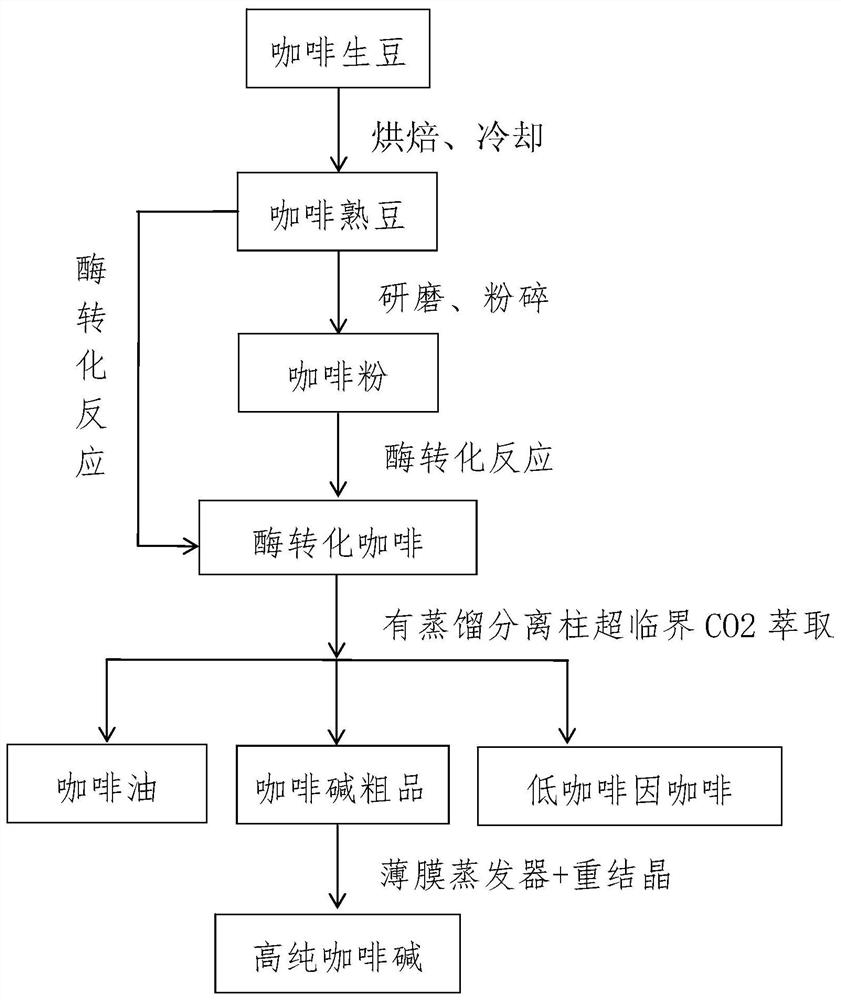

A caffeine and deep processing technology, applied in the direction of reducing the alkali content of coffee, coffee, coffee flavor, etc., can solve the problems of caffeine residue, market application restrictions, insufficient extraction of caffeine, etc., to achieve high recovery rate and improve economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

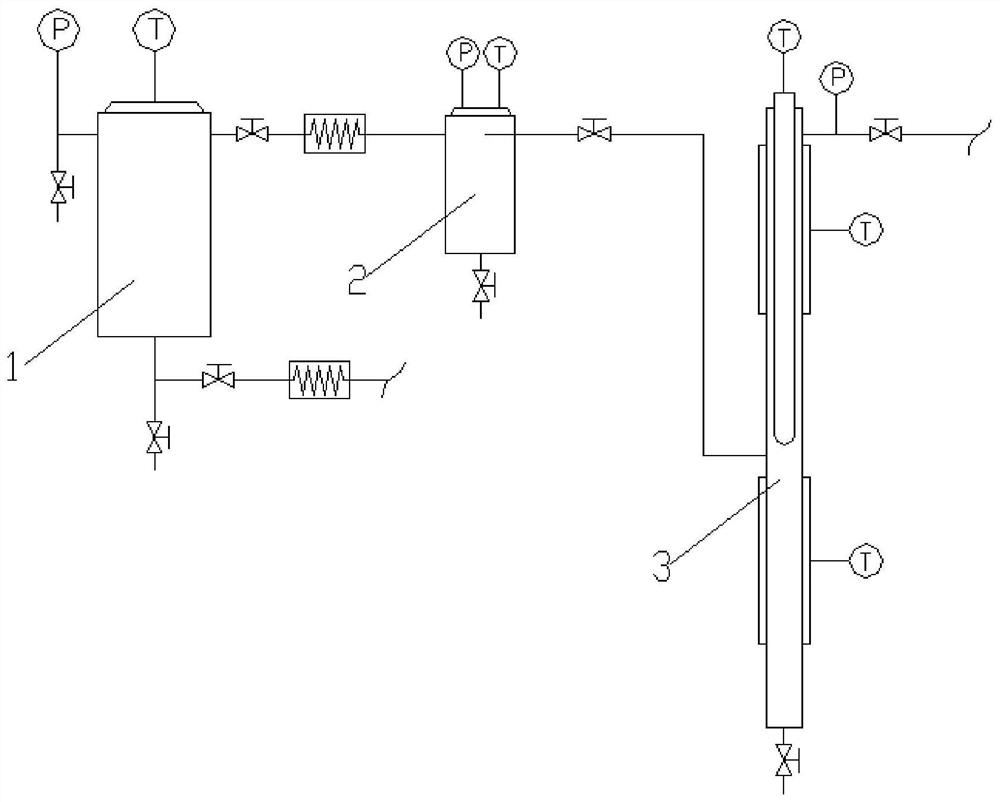

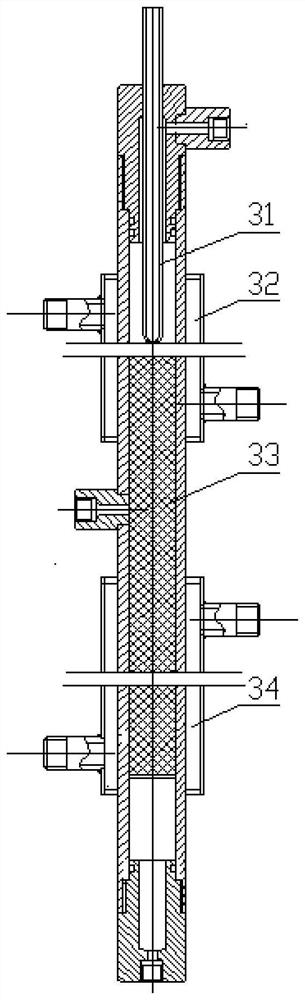

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Coffee Beans of the Arabica and Robusta Crossbred Varieties of the Genus Katim P3

[0035] Step (1) Roasting: Heat the green coffee beans with hot air at 80°C for 15 minutes to dehydrate them, then pour them into rolling hot sand at 200°C to allow the dehydrated coffee beans to be heated evenly to produce aromatic substances and coffee crema through complex chemical reactions. The reaction time is 15 minutes. After the reaction, quickly sieve and discharge the coffee beans and the silver skin on the surface. Immediately after baking, cool with cold air to lock the fat.

[0036] Step (2) Grinding: Grinding the roasted and cooled coffee beans to a particle size of 20 mesh, then adding 6% deionized water to the first crushed coffee beans, stirring evenly and then crushing to 50 mesh.

[0037]Step (3) Enzyme conversion reaction: Stir the crushed coffee powder with 8% 95 alcohol evenly and place it in an open container to allow natural fermentation and enzyme con...

Embodiment 2

[0042] Example 2: Catim P4, a cross between Arabica and Robusta

[0043] Step (1) Roasting: Heat the green coffee beans with hot air at 100°C for 10 minutes to dehydrate them, and then pour them into rolling hot sand at 190°C to allow the dehydrated coffee beans to be heated evenly to produce aromatic substances and coffee crema through complex chemical reactions. The reaction time is 20 minutes. After the reaction, quickly sieve and discharge the coffee beans and the silver skin on the surface. Immediately after baking, cool with cold air to lock the fat.

[0044] Step (2) Grinding: Grinding the roasted and cooled coffee beans to a particle size of 10 mesh, then adding 5% deionized water to the first crushed coffee beans, stirring evenly and then crushing to 60 mesh.

[0045] Step (3) Enzyme conversion reaction: add 10% 90% alcohol to the pulverized coffee powder, stir evenly and place it in an open container to let it ferment naturally for 20 hours.

[0046] Step (4) extra...

Embodiment 3

[0050] Embodiment 3: Robustas variety coffee beans

[0051] Step (1) Roasting: Heat the green coffee beans with hot air at 95°C for 15 minutes to dehydrate them, then pour them into rolling hot sand at 210°C to allow the dehydrated coffee beans to be heated evenly and complex chemical reactions will occur to produce aromatic substances and coffee crema. The reaction time is 20 minutes. After the reaction, quickly sieve and discharge the coffee beans and the silver skin on the surface. Immediately after baking, cool with cold air to lock the fat.

[0052] Step (2) Grinding: Grinding the roasted and cooled coffee beans to a particle size of 10 mesh, then adding 5% deionized water to the first crushed coffee beans, stirring evenly and then crushing to 60 mesh.

[0053] Step (3) Enzyme conversion reaction: add 10% 90% alcohol to the pulverized coffee powder, stir evenly and place it in an open container to allow natural fermentation and enzyme conversion for 6 hours.

[0054] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com