Fluorine cold wall type heat pump water heating device

A technology of heat pump hot water and fluorine cold wall, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of uneven distribution of refrigerant and low heating efficiency, achieve good heat preservation effect, increase heating speed, and improve thermal resistance big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

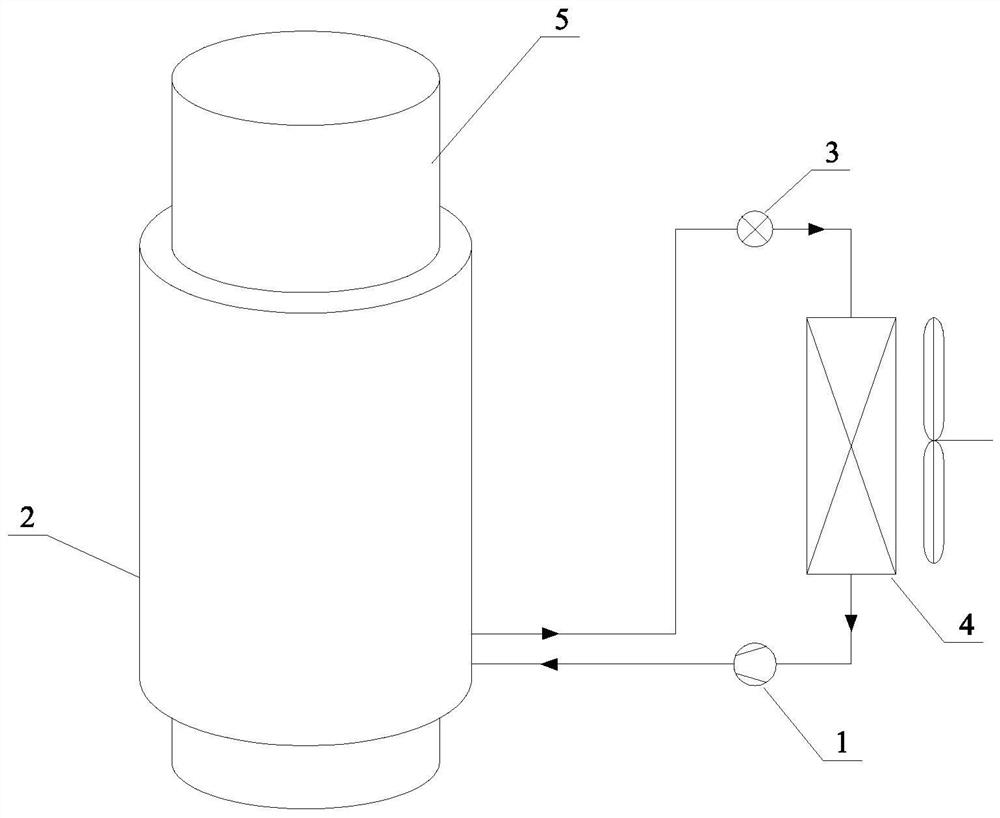

[0021] Such as figure 1 Shown, a fluorine cold wall heat pump water heater. Compressor (1), fluorine cold wall (2), throttle valve (3), evaporator (4), water tank (5), condensing coil (6) and fluorine cold wall working medium (7). The fluorine cold wall (2) is welded on the outer wall of the water tank (5) to form a closed annular cavity, and the condensing coil (6) is inserted into the space formed by the fluorine cold wall (2) and the water tank (5), and is isolated and sealed from the two . Fluorine cold wall (2) is filled with fluorine cold wall working medium (7).

[0022] The fluorine cold wall (2) is used as the heating equipment of the water tank (5), and is welded around the outer wall of the water tank (5).

[0023] The condensing coil (6) is inserted into the space formed by the fluorine cold wall (2) and the water tank (5), and is isolated and sealed from the two.

[0024] In the space formed by the fluorine cold wall (2) and the water tank (5), the fluorine co...

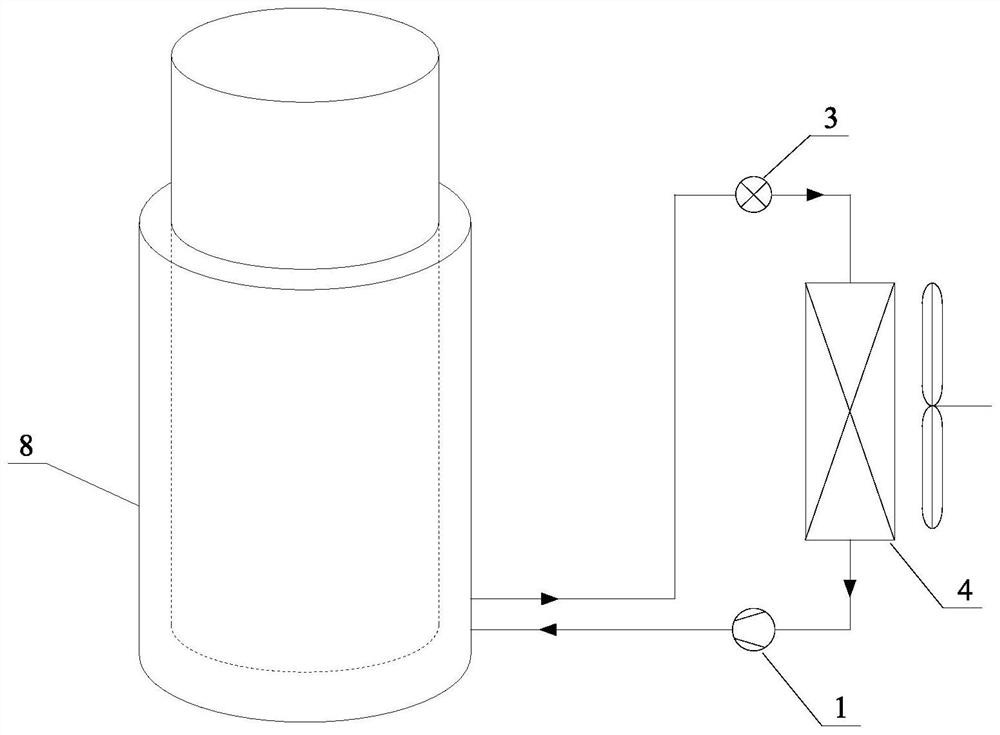

Embodiment 2

[0029] The bottom and the surrounding fluorine cold walls are integrated, and the interior is completely connected. The condensing coil (6) is arranged at the bottom, and can also be arranged at the bottom and around at the same time.

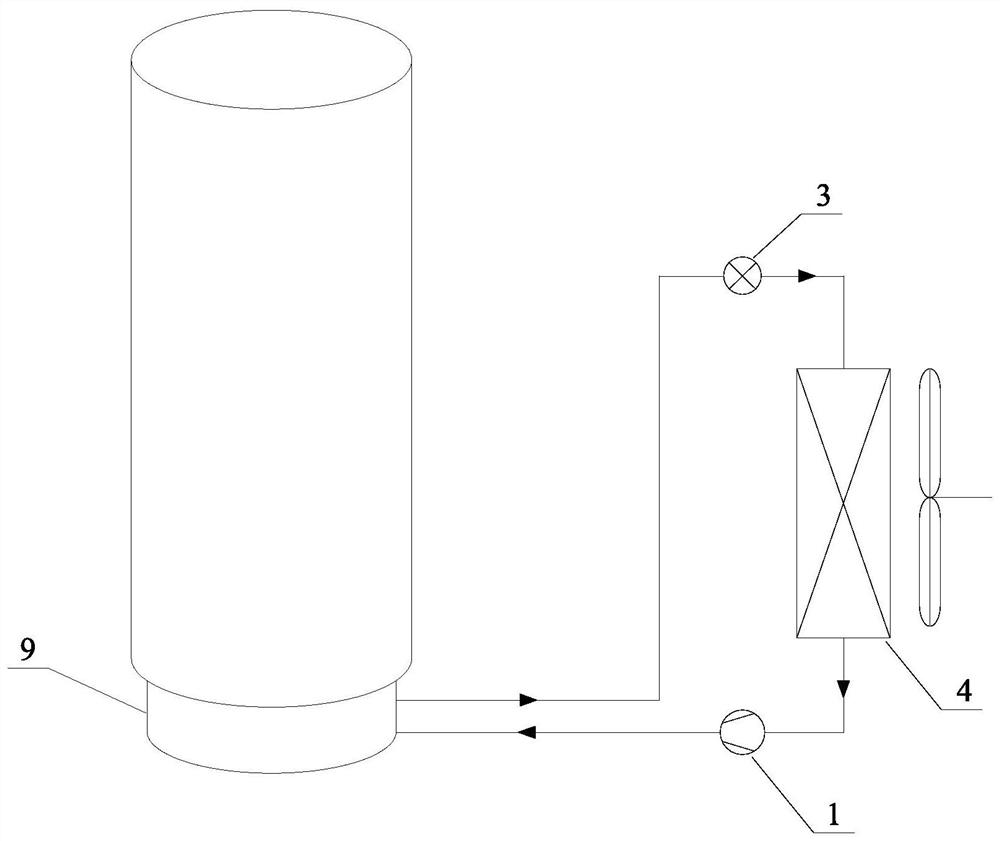

Embodiment 3

[0031] For the structure where only the fluorine cold wall is arranged at the bottom, the condensing coil (6) must be arranged at the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com