BMN multilayer dielectric film and preparation method thereof

A multilayer dielectric and thin film technology, applied in the field of microelectronics, can solve problems such as difficult control of dielectric film thickness and grain orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a Bi 1.5 MgNb 1.5 o 7 A method for preparing a multilayer dielectric film, comprising the following steps:

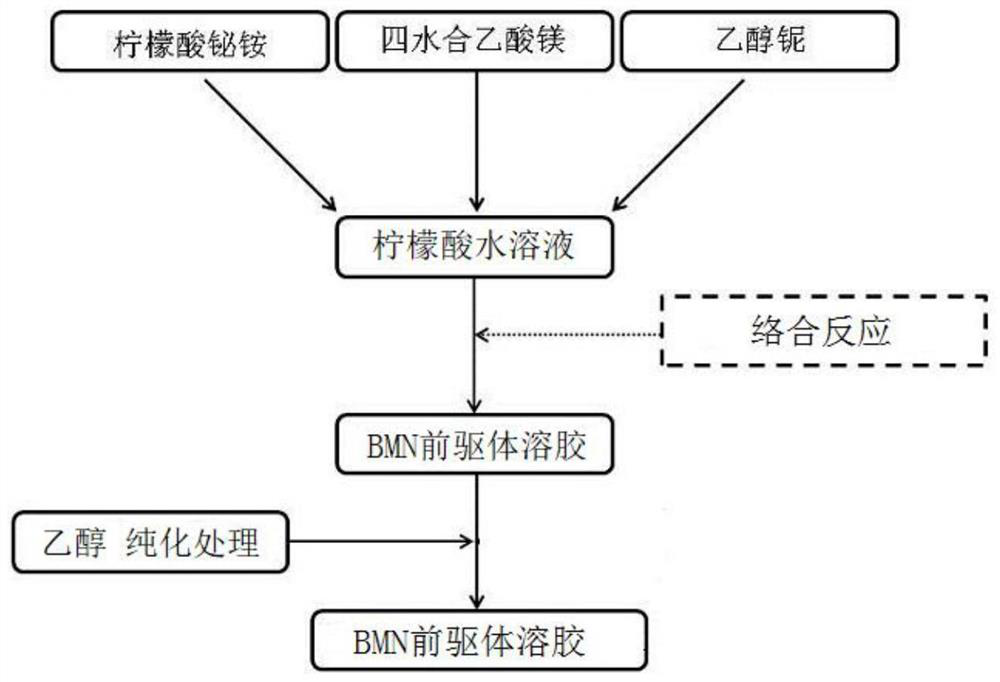

[0024] Mix ammonium bismuth citrate, magnesium acetate tetrahydrate, niobium ethoxide and citric acid aqueous solution, and carry out complexation reaction to obtain Bi-Mg-Ni precursor sol;

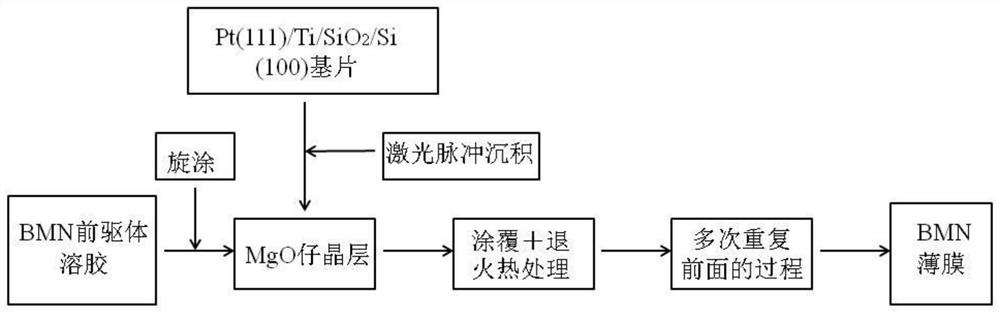

[0025] On Pt(111) / Ti / SiO by Laser Pulse Deposition 2 MgO is deposited on the surface of the / Si(100) substrate to obtain a MgO seed layer whose orientation is (111);

[0026] After coating the Bi-Mg-Ni precursor sol on the surface of the (111) MgO seed layer, performing annealing heat treatment to obtain a single-layer film;

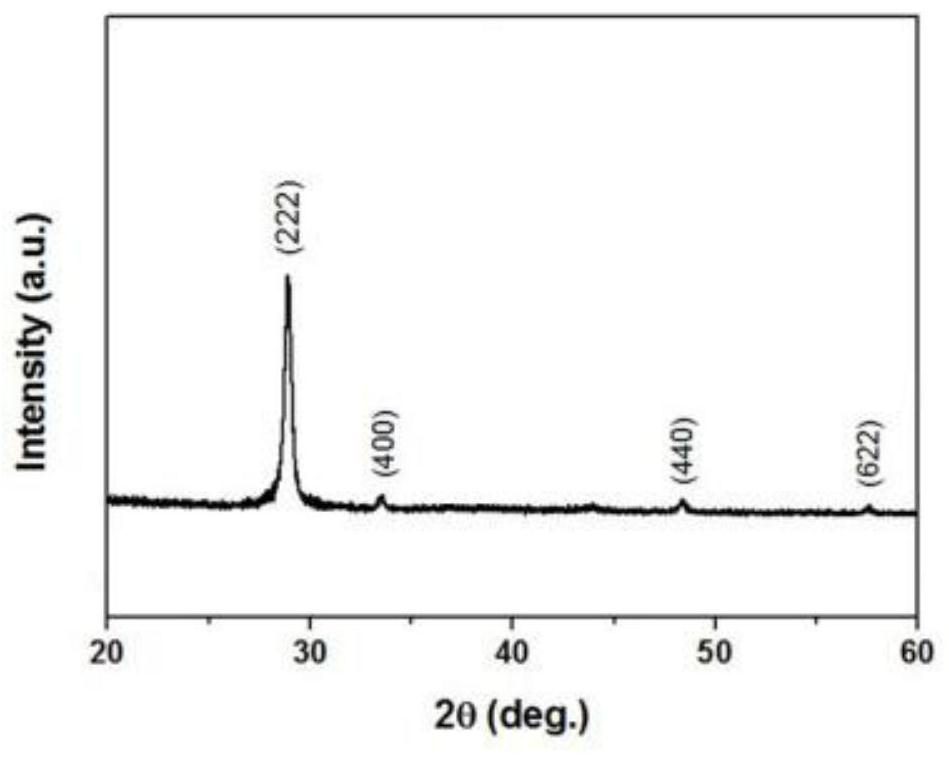

[0027] The single-layer film is repeatedly coated and annealed to obtain a BMN multilayer dielectric film with an orientation of (222).

[0028] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in the field or prepared by conventional methods in the...

Embodiment 1

[0046] Pt(111) / Ti / SiO 2 / Si(100) substrates were ultrasonically cleaned in deionized water for 10 minutes, ultrasonically cleaned in acetone for 10 minutes, ultrasonically cleaned in ethanol for 10 minutes, and ultrasonically cleaned in deionized water for 10 minutes, and then dried under infrared lamps;

[0047] Press Bi 1.5 MgNb 1.5 o 7 The stoichiometric ratio of 5.8461g ammonium bismuth citrate, 1.3034g magnesium acetate tetrahydrate and 2.9008g niobium ethylate were added to 50mL citric acid aqueous solution (citric acid and deionized water were used as solvent, and its molar ratio was 1:10). Stir at 250°C to carry out the complexation reaction, and after 15 minutes, the complexation reaction product is obtained;

[0048] The complexation reaction product and ethanol were mixed in a volume ratio of 1:1, purified at room temperature and under ultrasonic conditions, and after 0.5h, a Bi-Mg-Ni precursor sol was obtained;

[0049] Under the conditions of oxygen pressure o...

Embodiment 2

[0055] Pt(111) / Ti / SiO 2 / Si(100) substrates were ultrasonically cleaned in deionized water for 10 minutes, ultrasonically cleaned in acetone for 10 minutes, ultrasonically cleaned in ethanol for 10 minutes, and ultrasonically cleaned in deionized water for 10 minutes, and then dried under infrared lamps;

[0056] Press Bi 1.5 MgNb 1.5 o 7 Weigh 11.6992g of ammonium bismuth citrate, 2.6068g of magnesium acetate tetrahydrate and 5.8016g of niobium ethoxide into 90mL of citric acid aqueous solution (the molar ratio of citric acid to deionized water is 1:20), at 500°C Under stirring, carry out complexation reaction, after 1h, obtain complexation reaction product;

[0057] Mix the complexation reaction product and ethanol at a volume ratio of 1:1.5, perform purification treatment at room temperature and ultrasonic conditions, and obtain a Bi-Mg-Ni precursor sol after 1 hour;

[0058] Under the condition that the oxygen pressure is 30Pa, the laser energy is 400mJ, the laser freq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com