Novel rare earth nano-composite cleaning antibacterial antifogging agent as well as preparation method and application thereof

A nano-composite, anti-fogging agent technology, applied in chemical instruments and methods, other chemical processes, paints containing biocides, etc. To achieve the effect of enhanced hydrophilicity, good dispersion and adhesion, and prolonged anti-fog time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

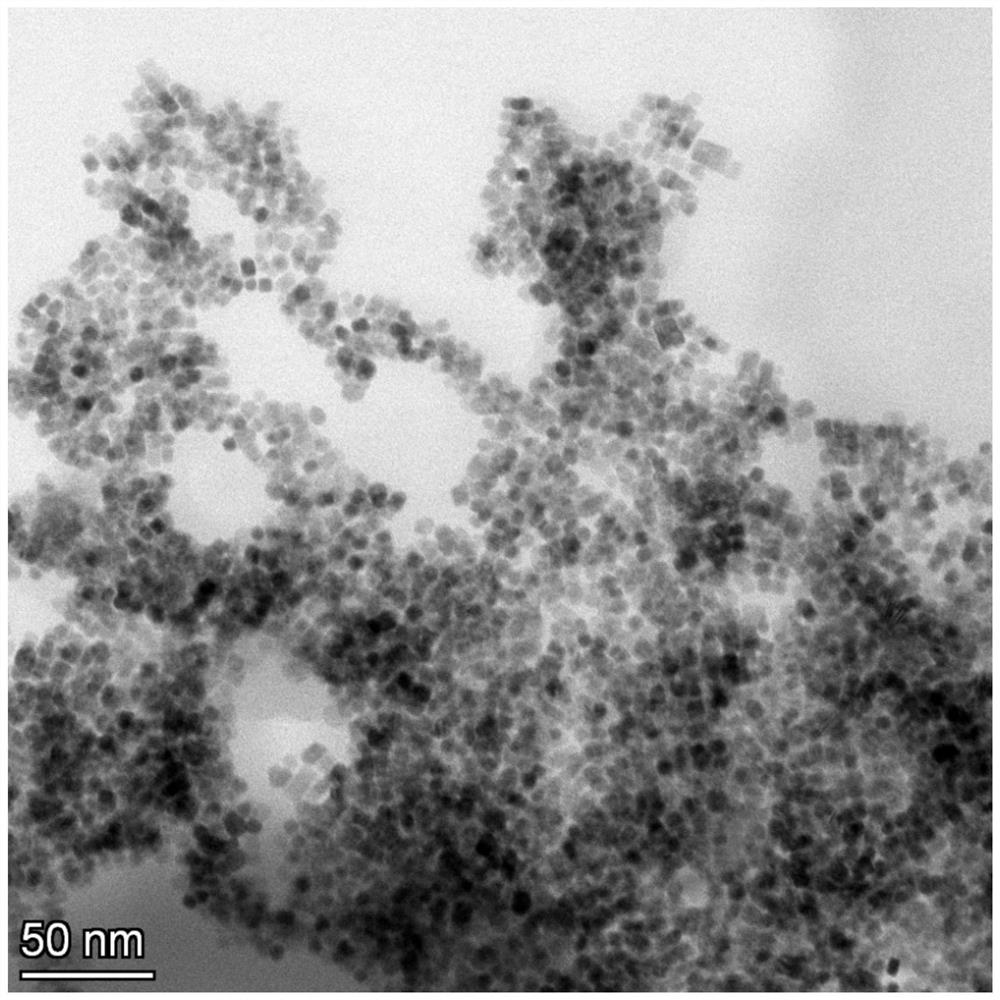

[0043] Nanoscale rare earth oxides were synthesized by sol-gel method, and the TEM scanning electron microscope images of nanoscale rare earth oxides are shown in figure 1 Synthesize rare earth-loaded nano-titanium dioxide by impregnation method, mix the two in proportion, and disperse evenly in the aqueous solution by ultrasonication for 5 minutes to obtain a nano-rare-earth oxide composite dispersion, and disperse the prepared nano-rare-earth oxide composite dispersion in a diluent Deionized water, then add solvent, surfactant, lubricant, chelating agent, mix and stir evenly to obtain a new type of rare earth nano-composite cleaning antibacterial antifogging agent. Wherein, the parts by weight of each component are as follows:

[0044]

[0045]

[0046] Wherein: the solvent is a mixed solution of ethanol and isopropanol in a weight ratio of 3:1; the weight ratio of alcohol ether glycoside AEG-10 and fluorocarbon surfactant is 9:1; the nano-rare earth oxide is nano-ceri...

Embodiment 2

[0075] Nano-scale rare earth oxides were synthesized by precipitation method, rare earth-loaded nano-titanium dioxide was synthesized by impregnation method, the two were mixed in proportion, and ultrasonically dispersed in aqueous solution for 40 minutes to obtain a composite dispersion of nano-rare earth oxides, and the prepared nano-rare earth The oxide composite dispersion liquid is dispersed in the diluent deionized water, then a solvent, a surfactant, a lubricant, and a chelating agent are added, and after mixing, the mixture is evenly stirred to obtain a new type of rare earth nano-composite cleaning, antibacterial and antifogging agent. Wherein, the parts by weight of each component are as follows:

[0076]

[0077]

[0078] Among them: the solvent is a mixed solution of ethanol and isopropanol in a weight ratio of 1:1; the weight ratio of cetyltrimethylammonium bromide and polyvinylpyrrolidone is 7:3; Lanthanum; rare earth-loaded nano-titanium dioxide is cerium-...

Embodiment 3

[0081] Nanoscale rare earth oxides were synthesized by hydrothermal method, rare earth loaded nano titanium dioxide was synthesized by impregnation method, the two were mixed in proportion, and ultrasonically dispersed in aqueous solution for 60 minutes to obtain nano rare earth oxide composite dispersion liquid, and the prepared nano The rare earth oxide composite dispersion liquid is dispersed in the diluent deionized water, then a solvent, a surfactant, a lubricant, and a chelating agent are added, and after mixing, the mixture is evenly stirred to obtain a new type of rare earth nanocomposite cleaning antibacterial and antifogging agent. Wherein, the parts by weight of each component are as follows:

[0082]

[0083]

[0084] Among them: the solvent is a mixture of ethanol and isopropanol in a weight ratio of 2:1; the weight ratio of polyvinyl alcohol and fluorocarbon surfactant is 5:2; the nano-rare earth oxide is nano-praseodymium oxide; the rare-earth-loaded nano-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com