Preparation and application of boric acid functionalized resin

A technology of resin and macroporous resin, which is applied in the field of preparation of natural product separation materials, can solve the problems of large solvent consumption, cumbersome operation process, cumbersome operation, etc., and achieve improved purity and yield, simple process route, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 10g of D101 resin into a three-necked round bottom flask, add 150mL 1,2-dichloroethane to swell overnight;

[0033] (2) Weigh 20g chloroacetyl chloride and add it to (1), then add 30g AlCl 3 , React for 12h at 40℃, after the reaction, filter the resin, wash it with ethanol and water several times, until the AgNO3 solution is added without precipitation, and finally vacuum dry to obtain the chloromethylated resin D101-Cl;

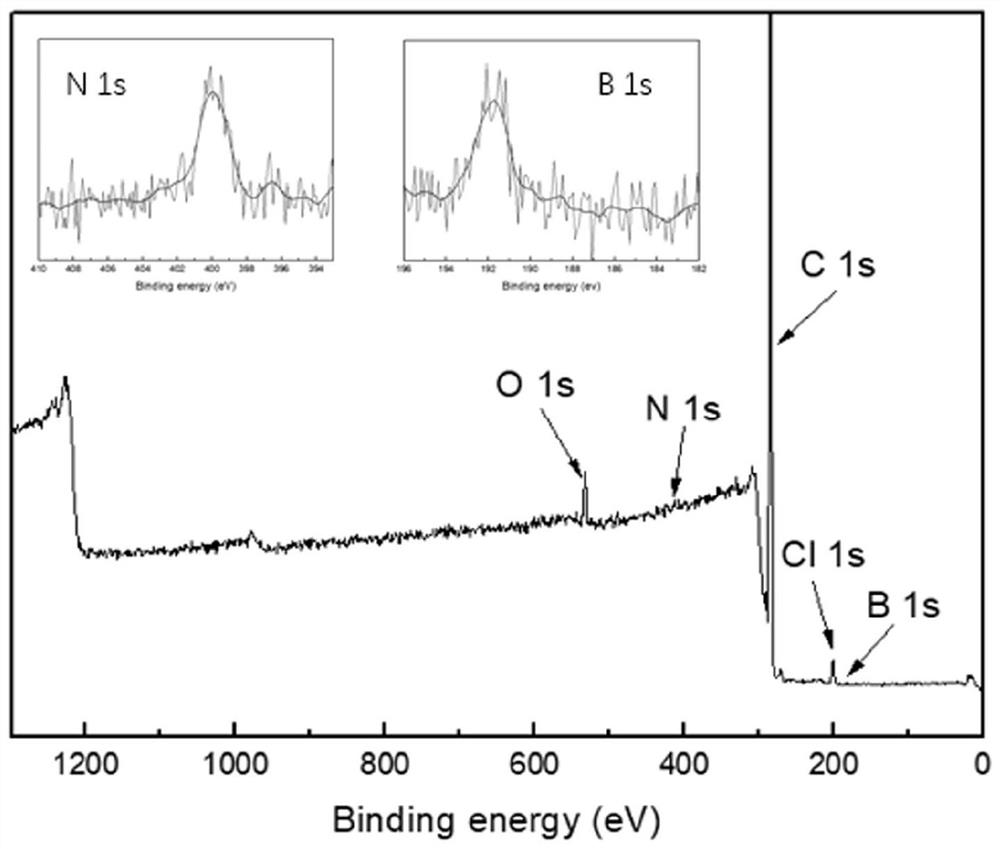

[0034] (3) Add 4g of D101-Cl to a three-necked round-bottom flask, add 100mL of 1,2-dichloroethane to swell overnight, add 2g of m-aminophenylboronic acid, and react for 12h at 60°C. After the reaction, discard the filtrate, and The resin was washed repeatedly with ethanol, HCl aqueous solution and distilled water, and finally dried under vacuum at 60°C for 12 hours to obtain the m-aminophenylboronic acid functionalized resin D101-BA, which passed the XPS spectrum ( figure 1 ) It can be seen that there are nitrogen and boron elements on the resin,...

Embodiment 2

[0038] (1) Weigh 10g of XAD-4 resin in a three-necked round-bottomed flask, add 150mL of 1,2-dichloroethane to swell overnight;

[0039] (2) Weigh 20g chloroacetyl chloride and add it to (1), then add 30g AlCl 3 , React at 40℃ for 12h, after the reaction, filter the resin, wash it with ethanol and water several times, until the AgNO3 solution is added without precipitation, and finally vacuum dry to obtain the chloromethylated resin XAD-4-Cl;

[0040] (3) Add 4g XAD-4-Cl to a three-necked round-bottom flask, add 100mL 1,2-dichloroethane to swell overnight, add 2g m-aminophenylboronic acid, and react at 60°C for 12h. After the reaction is over, discard the filtrate, The obtained resin was repeatedly washed with ethanol, HCl aqueous solution and distilled water, and finally vacuum dried at 60°C for 12 hours to obtain the m-aminophenylboronic acid functionalized resin XAD-4-BA. The XPS spectrum shows that there are nitrogen and boron on the resin, indicating the m-amino group Phenylbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com