Method for preparing electronic grade dimethoxymethane through lateral-line reactive extraction rectifying

An extractive rectification and extractive rectification tower technology, which is applied in the field of side-line reactive extraction and rectification to prepare electronic grade methylal, can solve the problems of complicated purification process, low purity of reaction products, high utilization cost of by-products, and reduce energy consumption. , the process is simple, the effect of improving the purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

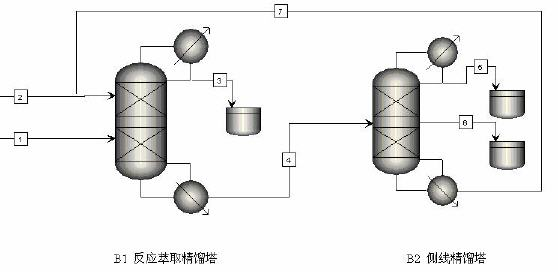

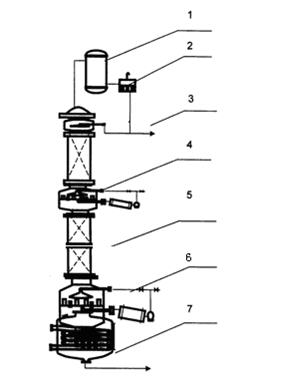

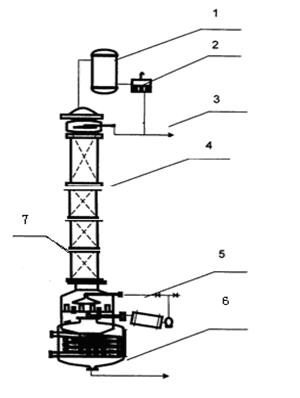

[0023] The method for preparing electronic-grade methylal by side line reaction extraction rectification of the present invention, with reference to figure 1 The process flow shown and the process condition parameters shown in Table 1 were carried out. The experiment was carried out under normal pressure, and the equipment such as figure 2 and image 3 As shown, the inner diameter of the tower is 22mm, and the φ3*3θ type stainless steel packing is installed inside. The height of the equal plate is 27mm as measured by the standard system.

[0024] Catalyst toluenesulfonic acid is added to the reactor of reactive extraction distillation column B1 at one time, the addition amount is 5.0kg, excess methanol and formaldehyde solution are added continuously by ①, the mass ratio of methanol and formaldehyde solution is 1.2~1.3:1.0, The extractant glycerin is continuously added by ②, with a flow rate of 100kg / h. The two materials ① and ② are simultaneously added to the tower kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com