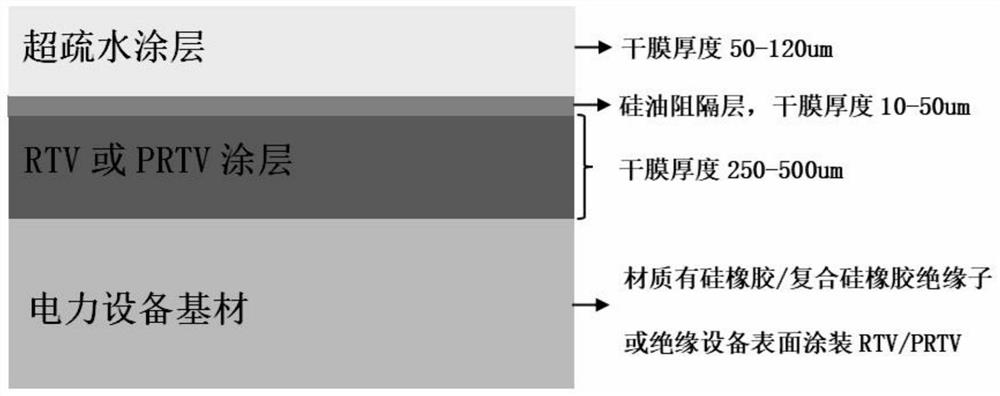

A kind of super-hydrophobic anti-pollution flashover coating that can be used on the surface of rtv/sr material and preparation method thereof

A super-hydrophobic, anti-fouling flashover technology, applied in antifouling/underwater coatings, devices for coating liquid on the surface, coatings, etc., can solve the problems of insufficient hydrophobicity and dust accumulation, and achieve improved antifouling flashover ability, comprehensive performance, and the effect of improving outdoor aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

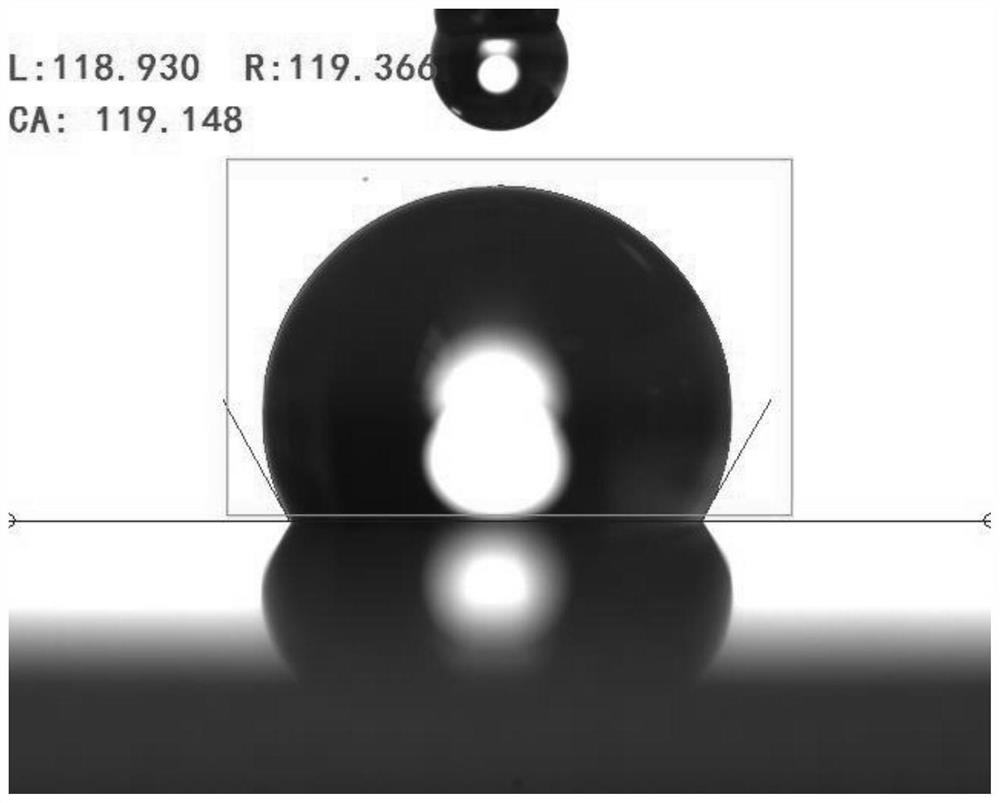

[0039] A super-hydrophobic self-cleaning ceramic insulator is used for 110KV transmission tower power equipment. The outer surface of the above-mentioned insulator body has been coated with an old RTV coating, and the thickness of the old coating is about 500um. Before spraying the superhydrophobic anti-pollution flashover coating, the contact angle to water is 90°, and the rolling angle is 80°. The above samples are sprayed with superhydrophobicity. The preparation method of super self-cleaning coating comprises the following steps:

[0040] 1) Clean the surface dust and oil on the silicone rubber (SR) insulator, requiring no oil, no dust, no water marks, and no solvent.

[0041] 2) A layer of silicone oil barrier layer is coated on the surface, and the type of the barrier layer is 10 parts of epoxy resin, 1 part of epoxy curing agent, and 1 part of epoxy thinner. Dry at room temperature 25°C for 30min. The thickness of the coating is 50um after drying.

[0042] 3) Surface...

Embodiment 2

[0045] A super-hydrophobic composite silicone rubber insulator is used for outdoor power equipment in 220KV substations. The above insulators are made of synthetic silicone rubber with no coating on the surface. Before spraying the super-hydrophobic anti-pollution flashover paint, the contact angle to water is 100°, and the rolling angle is 60°. The preparation method of the above-mentioned sample sprayed with the super-hydrophobic and super-self-cleaning paint comprises the following steps:

[0046] 1) Clean the surface dust and oil on the composite silicone rubber insulator, requiring no oil, no dust, no water marks, and no solvent.

[0047] 2) A layer of silicone oil barrier layer is coated on the surface, and the type of the barrier layer is 12 parts of epoxy resin, 1 part of epoxy curing agent, and 1 part of epoxy thinner. Dry at room temperature 25°C for 30min. The thickness of the coating after drying is 60um.

[0048] 3) The surface is coated with a super-hydrophobi...

Embodiment 3

[0051] A super-hydrophobic composite cross-arm insulator is used for outdoor electrical equipment of outdoor 35KV substations. The above insulators are made of synthetic silicone rubber with no coating on the surface. Before spraying the super-hydrophobic anti-pollution flashover paint, the contact angle to water is 90°, and the rolling angle is 70°. The preparation method of the above-mentioned sample sprayed with the super-hydrophobic and super-self-cleaning paint comprises the following steps:

[0052] 1) Clean the surface dust and oil on the composite silicone rubber insulator, requiring no oil, no dust, no water marks, and no solvent.

[0053] 2) A layer of silicone oil barrier layer is coated on the surface, and the type of the barrier layer is 11 parts of epoxy resin, 1 part of epoxy curing agent, and 0.8 part of epoxy thinner. Dry at room temperature 25°C for 30min. The thickness of the coating after drying is 60um.

[0054] 3) The surface is coated with a superhydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com