Anti-pollution flashover porcelain insulator and production method thereof

A ceramic insulator, anti-pollution flashover technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of not being smooth enough, shortening the service life of ceramic insulators, and glazing with air bubbles, so as to improve the flatness and mechanical properties, and improve anti-fouling Lightning performance, the effect of low surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

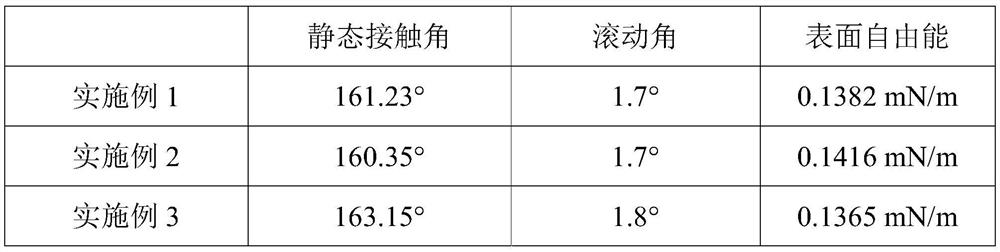

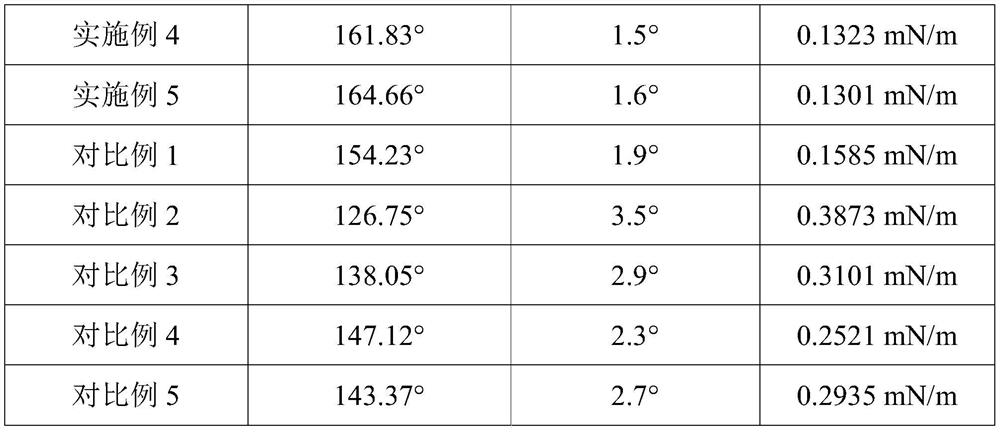

Examples

Embodiment 1

[0038] An anti-pollution flash porcelain insulator, which sequentially includes a porcelain insulator base, a filling layer, and a superhydrophobic coating from the inside to the outside; wherein, the coating used for the filling layer includes the following raw materials by weight: SiO 2 -Al 2 o 3 -ZrO 2 20 parts of composite sol, 10 parts of bauxite, 0.5 parts of sodium tripolyphosphate, 0.5 parts of sodium dihydrogen phosphate, 5 parts of silane coupling agent; the superhydrophobic coating is coated on the porcelain insulator substrate by fluorinated sol solution and dried Formed, the fluorinated sol solution includes SiO 2 -La 2 o 3 Sol, hydrophobic fumed nano silica, fluorinating agent and silane coupling agent, the mass ratio is 10:1:1:1.

[0039] The preparation method of the anti-pollution flash porcelain insulator of this embodiment comprises the following steps:

[0040] S1. Preparation of superhydrophobic coating:

[0041] S11, preparation of SiO 2 -La 2 o ...

Embodiment 2

[0048] An anti-pollution flash porcelain insulator, which sequentially includes a porcelain insulator base, a filling layer, and a superhydrophobic coating from the inside to the outside; wherein, the coating used for the filling layer includes the following raw materials by weight: SiO 2 -Al 2 o 3 -ZrO 2 30 parts of composite sol, 5 parts of bauxite, 3 parts of sodium tripolyphosphate, 3 parts of sodium dihydrogen phosphate, 10 parts of silane coupling agent; the superhydrophobic coating is coated on the base of the porcelain insulator by fluorinated sol solution and dried Formed, the fluorinated sol solution includes SiO 2 -La 2 o 3 Sol, hydrophobic fumed nano silica, fluorinating agent and silane coupling agent, the mass ratio is 10:3:2:2.

[0049] The preparation method of the anti-pollution flash porcelain insulator of this embodiment comprises the following steps:

[0050] S1. Preparation of superhydrophobic coating:

[0051] S11, preparation of SiO 2 -La 2 o 3...

Embodiment 3

[0058] An anti-pollution flash porcelain insulator, which sequentially includes a porcelain insulator base, a filling layer, and a superhydrophobic coating from the inside to the outside; wherein, the coating used for the filling layer includes the following raw materials by weight: SiO 2 -Al 2 o 3 -ZrO 2 27 parts of composite sol, 8 parts of bauxite, 2 parts of sodium tripolyphosphate, 2 parts of sodium dihydrogen phosphate, and 7 parts of silane coupling agent; the superhydrophobic coating is coated on the base of the porcelain insulator by fluorinated sol solution and dried Formed, the fluorinated sol solution includes SiO 2 -La 2 o 3 Sol, hydrophobic fumed nano silica, fluorinating agent and silane coupling agent, the mass ratio is 10:2:1.5:1.5.

[0059] The preparation method of the anti-pollution flash porcelain insulator of this embodiment comprises the following steps:

[0060] S1. Preparation of superhydrophobic coating:

[0061]S11, preparation of SiO 2 -La ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com