Super-hydrophobic metal net based on bionic mussels as well as preparation method and application of super-hydrophobic metal net

A metal mesh, super-hydrophobic technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of high preparation cost, single performance, poor environmental protection, etc. Good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

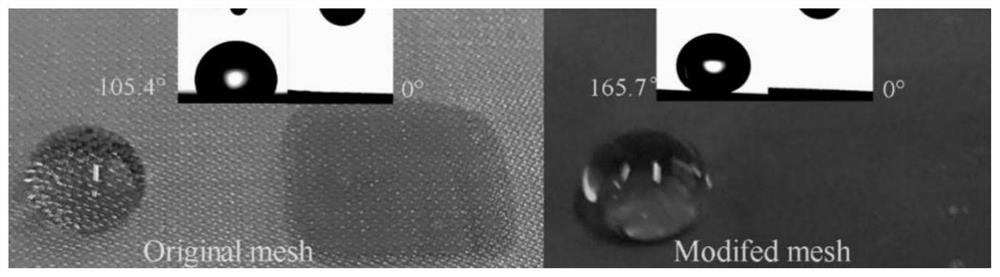

[0042] A kind of superhydrophobic metal net and preparation method thereof are as follows:

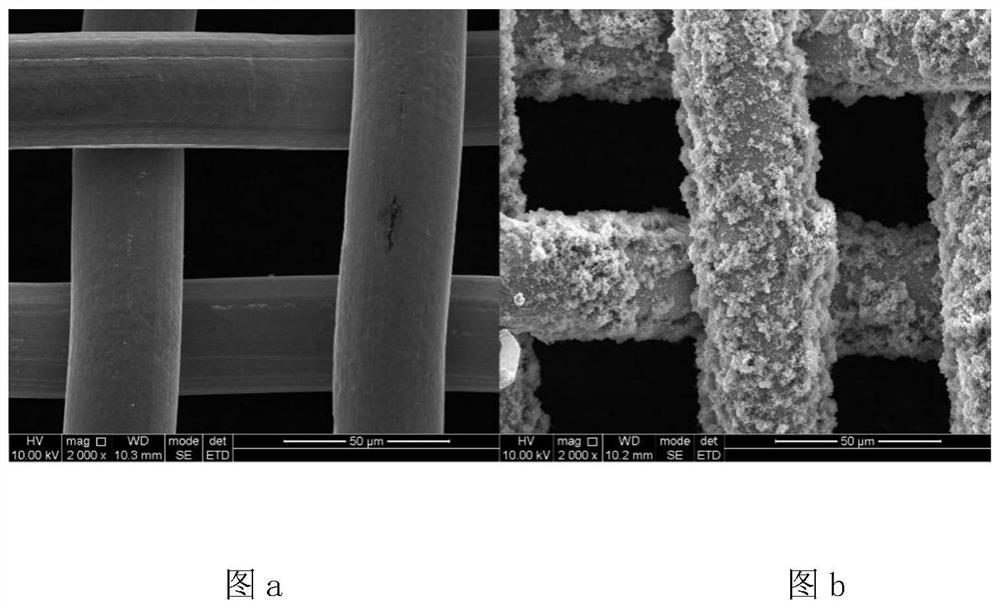

[0043] (1) Pretreatment of metal mesh. Cut the 300-mesh stainless steel wire mesh into 40×40mm squares, soak it in dilute hydrochloric acid solution and absolute ethanol successively, and ultrasonically clean it for 20 minutes to remove surface oxides and grease. Dry in the oven for later use.

[0044](2) Preparation of Tris-HCl (0.01 mol / L) buffer solution: 1.576 g of Tris-HCl was dissolved in 1 L of solution to prepare a 10 mM buffer solution.

[0045] (3) Place the metal mesh obtained in step (1) in a 1.5 mg / mL dopamine hydrochloride solution, adjust the pH of the solution to 8.5 with Tris-HCl buffer, stir and react in a water bath for 24 hours at a temperature of 60°C, After washing several times with pure water, dry at 60° for later use.

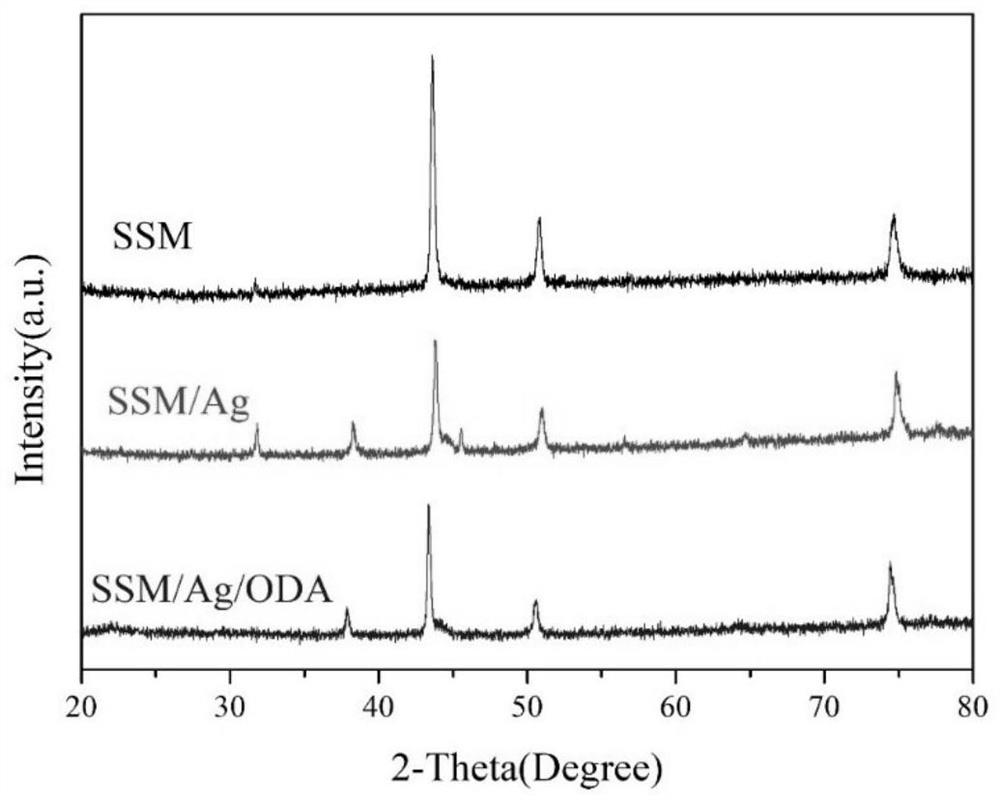

[0046] (4) the metal mesh that step (3) is obtained is placed in the silver nitrate solution of 12mM, reacts 12h on the magnetic stirrer, an...

Embodiment 2

[0059] A kind of superhydrophobic metal net and preparation method thereof are as follows:

[0060] (1) Pretreatment of metal mesh. Cut the 400-mesh stainless steel wire mesh into a 40×40mm square, soak it in acetone and absolute ethanol successively, and ultrasonically clean it for 20 minutes to remove surface oxides and grease. After taking it out, wash it with pure water several times, and place it in a vacuum drying oven. Dry in medium.

[0061] (2) Preparation of Tris-HCl (0.01 mol / L) buffer solution: 1.576 g of Tris-HCl was dissolved in 1 L of solution to prepare a 10 mM buffer solution.

[0062] (3) The metal mesh obtained in step (1) was placed in a 1.5 mg / mL dopamine hydrochloride solution, and the pH of the solution was adjusted to 8.5, and Tris-HCl buffer was used for adjustment. Stir and react at 30°C for 24h, wash with pure water repeatedly, and dry (60°) for later use.

[0063] (4) Place the metal mesh obtained in step (3) in a 12mM silver nitrate solution, re...

Embodiment 3

[0067] A kind of superhydrophobic metal net and preparation method thereof are as follows:

[0068] (1) Pretreatment of metal mesh. Cut the 200-mesh stainless steel wire mesh into a 40×40mm square, soak it in acetone and absolute ethanol successively, and ultrasonically clean it for 20 minutes to remove surface oxides and grease. After taking it out, wash it with pure water several times, and place it in a vacuum drying oven. Dry in medium.

[0069] (2) Preparation of Tris-HCl (0.01 mol / L) buffer solution: 1.576 g of Tris-HCl was dissolved in 1 L of solution to prepare a 10 mM buffer solution.

[0070] (3) Place the metal mesh obtained in step (1) in a 1.5 mg / mL dopamine hydrochloride solution, adjust the pH to 8.5 with Tris-HCl buffer, stir and react in a water bath for 24 hours at a temperature of 60°C, and use After washing with pure water several times, dry at 60° for later use.

[0071] (4) The metal mesh obtained in step (3) was placed in a 15 mM silver nitrate soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com