Bone repair material and preparation method and application thereof

A bone repair and material composition technology, applied in the field of medical biomaterials, to achieve the effects of simple and easy preparation methods, prevention of postoperative infection, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

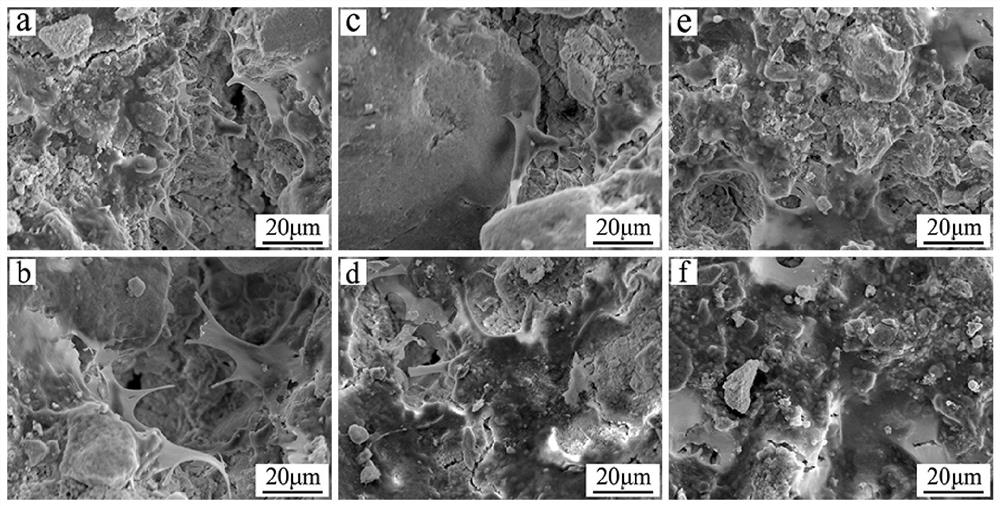

Image

Examples

Embodiment 1

[0090] Embodiment 1: The preparation method of bone cement bone repair material, comprises the following steps:

[0091] (1) Disperse hydroxyapatite particles into 200 μmol / L lipoic acid solution, stir for 2 hours, and then centrifuge and dry to obtain the desired drug-loaded hydroxyapatite particles;

[0092] (2) Dissolve sodium phytate in water at a concentration of 5w%.

[0093] (3) The bone cement powder is magnesium oxide, calcium hydrogen phosphate, sodium dihydrogen phosphate and hydroxyapatite, in which magnesium oxide, calcium hydrogen phosphate and sodium dihydrogen phosphate are uniformly mixed in a molar ratio of 5:6:2.

[0094] (4) Mix 0.08g of drug-loaded hydroxyapatite particles with 0.32g of magnesium phosphate bone cement powder evenly, take 180mg of desolidified liquid and mix it with the powder, and place it in the mold at 37 ℃, 100% humidity environment to cure 72h.

Embodiment 2

[0095] Embodiment 2: the preparation method of bone cement bone repair material, comprises the following steps:

[0096] (1) Disperse hydroxyapatite particles into 200 μmol / L lipoic acid solution, stir for 2 hours, and then centrifuge and dry to obtain the desired drug-loaded hydroxyapatite particles;

[0097] (2) Dissolve sodium phytate in water at a concentration of 5w%.

[0098] (3) The bone cement powder is magnesium oxide, calcium hydrogen phosphate, sodium dihydrogen phosphate and hydroxyapatite, in which magnesium oxide, calcium hydrogen phosphate and sodium dihydrogen phosphate are uniformly mixed in a molar ratio of 2:2:1 。

[0099] (4) Mix 0.08g of drug-loaded hydroxyapatite particles with 0.32g of magnesium phosphate bone cement powder evenly, take 150mg of desolidified liquid and mix it with the powder, put it into the mold and solidify (the solidification time is 6-10min) and place it in 37 ℃, 100% humidity environment to cure 72h.

Embodiment 3

[0100] Embodiment 3: the preparation method of bone cement composite bone repair material, it comprises the following steps:

[0101] (1) The bone cement powder is magnesium oxide, calcium hydrogen phosphate, sodium dihydrogen phosphate and hydroxyapatite, in which magnesium oxide, calcium hydrogen phosphate and sodium dihydrogen phosphate are uniformly mixed in a molar ratio of 5:6:2.

[0102] (2) Dissolve sodium phytate in water at a concentration of 5w%.

[0103] (3) Add 0.02g lipoic acid powder and 0.06g hydroxyapatite to the bone cement powder and mix evenly.

[0104] (4) Mix the drug-loaded bone cement powder evenly, take 180mg of solidification liquid and mix it with the powder, put it into the mold to solidify (solidification time is 6-10min), and then place it in an environment of 37°C and 100% humidity for 72h to solidify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com