A lithium battery positive electrode material and preparation method thereof, and all-solid lithium battery

A technology of positive electrode material and positive electrode active material, which is applied in the field of lithium battery materials, can solve the problem of high temperature reaction between solid electrolyte and positive electrode active material, and achieves the effect of simple and easy preparation method, ensuring stability and avoiding high temperature reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In a second aspect, the present invention provides a method for preparing the above-mentioned positive electrode material for a lithium battery, comprising the following steps:

[0043] 1) Preparation of sol: Al(NO 3 ) 3 Aqueous solution, adding one or more of basic compounds such as ammonia water, sodium hydroxide, potassium hydroxide and other basic compounds to adjust the pH to 7.5-10.8 to obtain hydrated alumina sol;

[0044] 2) Preparation of positive electrode material precursor: The molar ratio of lithium source, positive electrode active material and sol obtained in step (1) is 1-x: 5+y / 3 (0≤x≤0.1, 0≤y≤x ) to mix, heat to 60-80°C, and add positive electrode active material after it is uniformly dispersed, wherein, the molar ratio of lithium source to positive electrode active material is (0.0003-0.1):1, and stir at 60-80°C for 1 -24h, and dry at 80-150°C for use to obtain the precursor of the positive electrode material;

[0045] 3) Preparation of positive el...

Embodiment 1

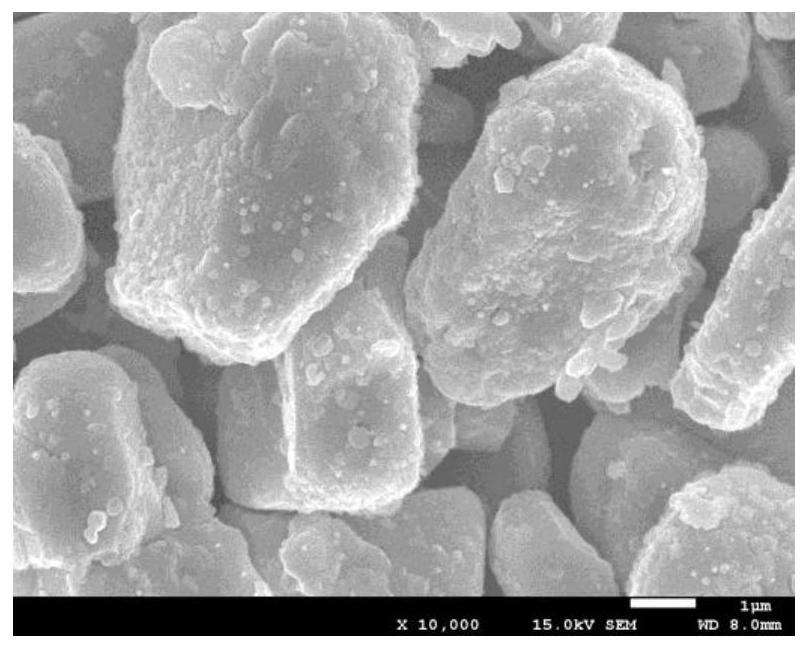

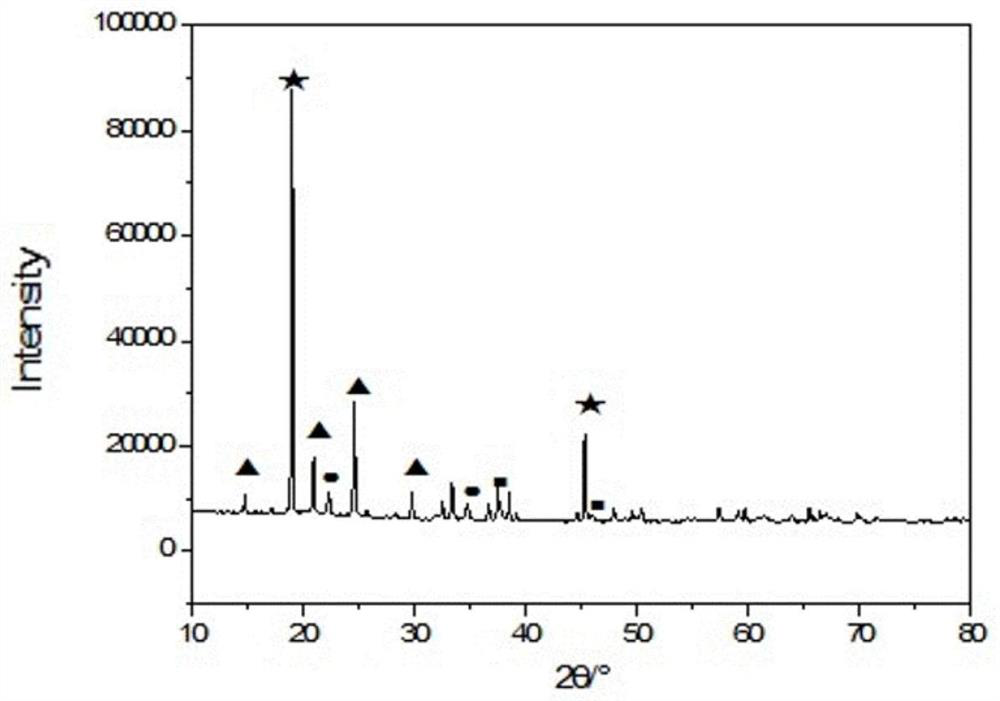

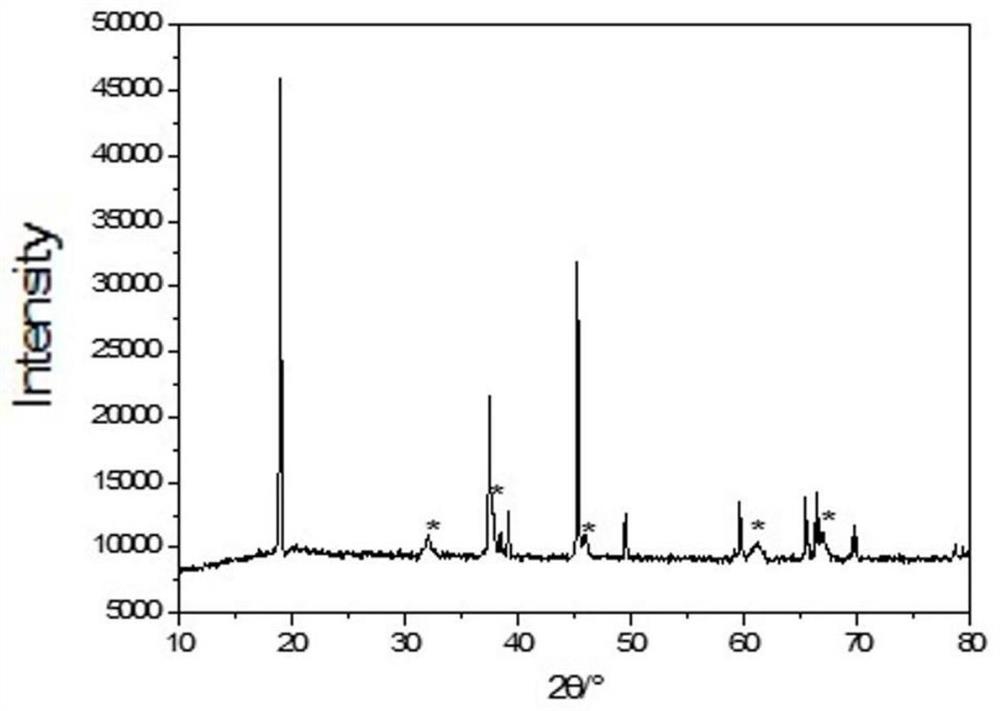

[0064] The active material is LiCoO 2 , coated in LiCoO 2 The material on the particle surface is LiAlO 2 and LiAl 5 o 8 , where LiCoO 2 with LiAlO 2 and LiAl 5 o 8 The mass ratio is 100:8:3;

[0065] The specific synthesis method is:

[0066] 1) Preparation of sol: use 100mL H 2 O dissolves 32.51g Al(NO 3 ) 3 , Place the solution in a three-necked flask, slowly add ammonia water drop by drop while stirring, the end point of the addition is pH=8. After the dropwise addition, the solution gradually became a milky white suspension, and the colloid obtained after the suspension was filtered and washed was hydrated alumina sol (30wt% Al 3+ );

[0067] 2) Preparation of cathode material precursor: take 10g LiCoO 2 , 1.590 g of the hydrated alumina sol prepared above, 0.317 g of lithium hydroxide and 50 mL of ethanol were put into a three-necked flask, placed in a water bath at 80°C for condensing and reflux for 5 hours, filtered and washed the precipitate, and dried f...

Embodiment 2

[0072] The active material is LiNi 0.8 co 0.1 mn 0.1 o 2 , coated in LiNi 0.8 co 0.1 mn 0.1 o 2 The material on the particle surface is LiAlO 2 and Li 0.517 al 5.161 o 8 , where LiCoO 2 with LiAlO 2 and Li 0.517 al 5.161 o 8 The mass ratio is 100:8:3;

[0073] The specific synthesis method is:

[0074] 1) Sol preparation: use 100mL H 2 O dissolves 32.51g Al(NO 3 ) 3 , Place the solution in a three-necked flask, slowly add ammonia water drop by drop while stirring, the end point of the addition is pH=8. After the dropwise addition, the solution gradually became a milky white suspension. The colloid obtained after suction filtration and washing of the suspension is the hydrated alumina sol (30wt% Al 3+ );

[0075] 2) Preparation of cathode material precursor: take 10g LiNi 0.8 co 0.1 mn 0.1 o 2 1.605 g of the hydrated alumina sol prepared above, 0.304 g of lithium hydroxide and 50 mL of ethanol were put into a three-necked flask, and placed in a water b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com