Industrial boiler pressure gauge structure

A technology for industrial boilers and pressure gauges, applied in the field of instruments, can solve the problems of simple structure, weak stability and poor protection performance of pressure gauges, and achieve the effects of accurate measurement results, guaranteed stability and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

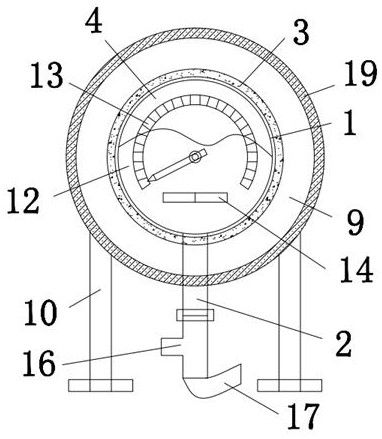

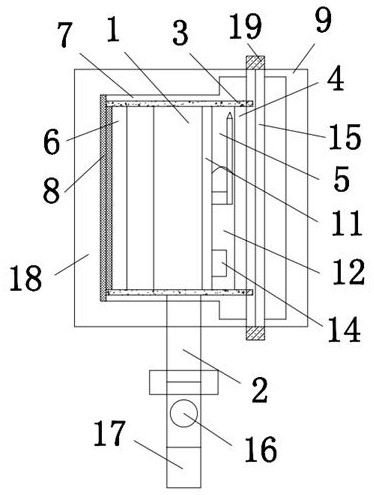

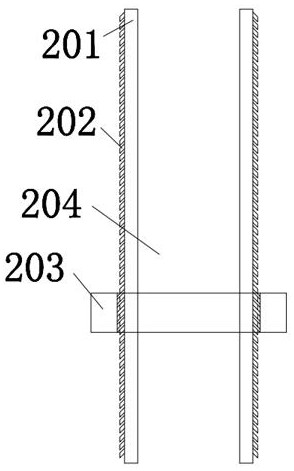

[0037] see Figure 1-2 , an industrial boiler pressure gauge structure, including a pressure gauge body 1 and a housing 18, the bottom of the pressure gauge body 1 is fixedly connected with a communication mechanism 2, the peripheral side of the pressure gauge body 1 is fixedly connected with a fixed cylinder 3, and the fixed cylinder 3 The inner front end is fixedly connected with the first toughened glass 4, and a cavity 5 is formed between the first toughened glass 4 and the pressure gauge body 1, the inner rear end of the fixed cylinder 3 is fixedly connected with the rear cover 6, and the rear inner wall of the housing 18 is opened There is a groove 7 corresponding to the fixed cylinder 3, a magnet 8 is fixedly connected to the front of the rear cover 6 and the rear inner wall of the groove 7, and two sets of magnets 8 are magnetically connected, and the front of the housing 18 is bonded and connected with a sealing mechanism 9. The outer side of the connection between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com