Liquid nitrogen cooling and fireproof device for coal mine

A fire prevention device, liquid nitrogen technology, applied in mining equipment, fire prevention, safety devices, etc., can solve the problems of lack of fire prevention ability, unreliable detection of internal temperature of coal powder and other accumulations, rough temperature detection, etc., to achieve practicality Strong, reduce temperature, save liquid nitrogen effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

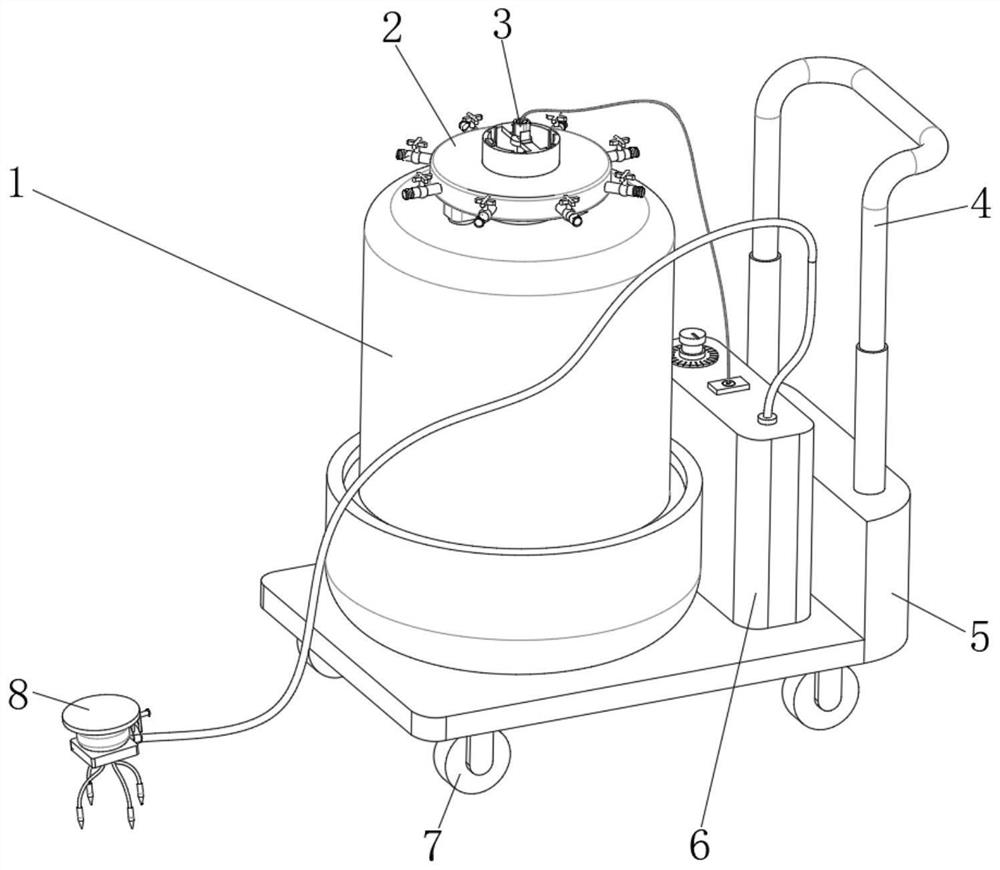

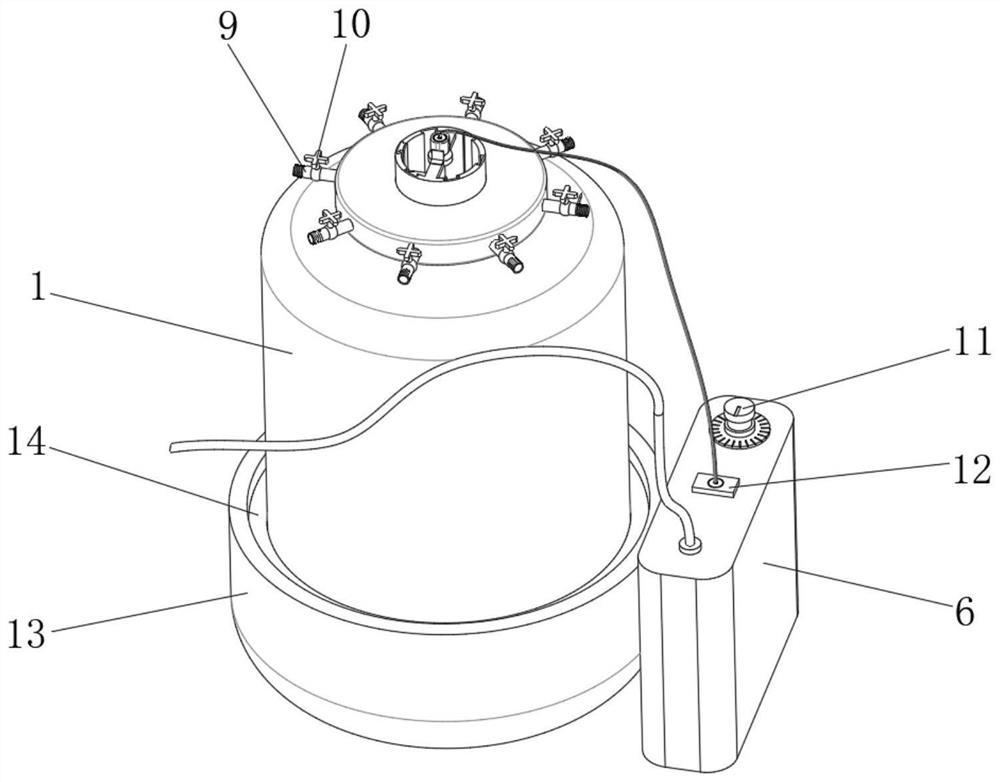

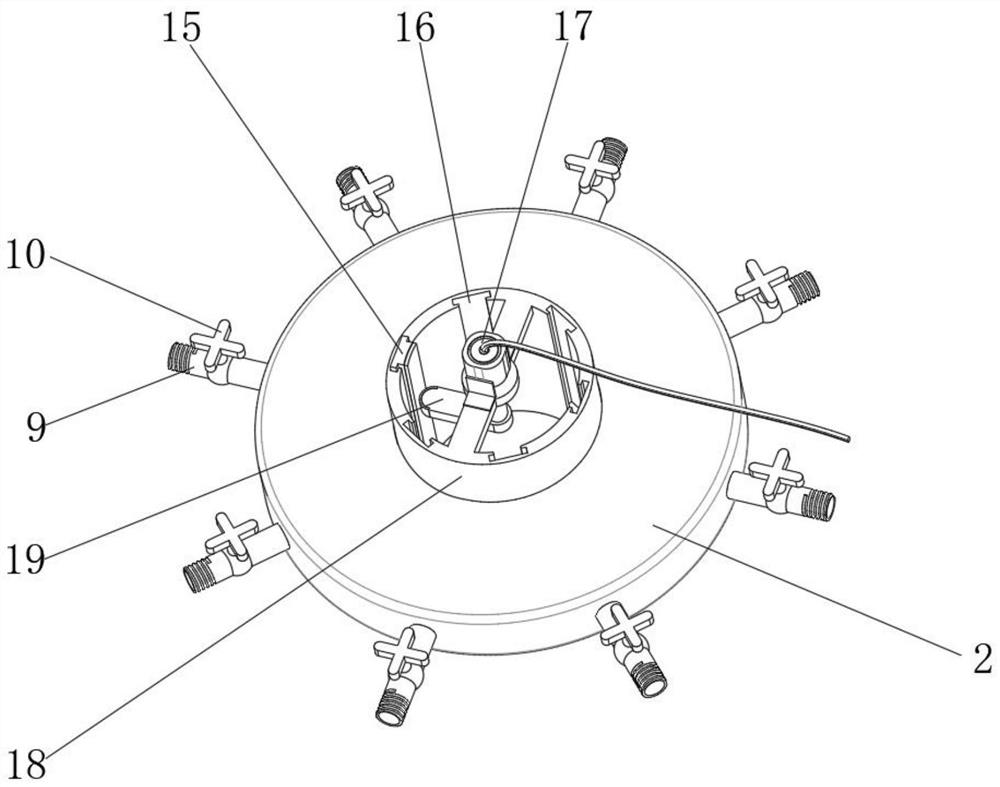

[0035] A kind of liquid nitrogen cooling fire prevention device for coal mine, such as Figure 1-6As shown, it includes a liquid nitrogen device 1 and a monitoring mechanism 8. A control chamber 6 is provided on one side of the liquid nitrogen device 1. An electric control valve 20 is provided at the output end of the liquid nitrogen device 1. The electric control valve 20 is electrically connected to the control chamber 6. Sexual connection, the monitoring mechanism 8 includes a heat transfer plug 26, a mounting frame 21 and an expansion air bag 22, the inner wall of the mounting frame 21 is fixed with a heat conduction column 28 by screws, the expansion air bag 22 is set on the outer wall of the heat conduction column 28, and the heat conduction column 28 The outer wall matches the size of the expansion airbag 22, and the heat transfer plugs 26 are respectively connected to the outer wall at the bottom of the heat conduction column 28 through the heat conduction wire 27. One...

Embodiment 2

[0046] A kind of liquid nitrogen cooling fire prevention device for coal mine, such as Figure 1-6 As shown, in order to save liquid nitrogen; this embodiment makes the following improvement on the basis of embodiment 1: the two conductive sheets 24 are connected in series with the metal insert 15 and the conductive head 19 instead.

[0047] When this embodiment is in use, by arranging structures such as the metal insert 15 and the conductive head 19, since the two conductive sheets 24 are connected in series with the metal insert 15 and the conductive head 19, when the temperature exceeds the standard, the rotation of the motor 17 can be controlled. , to achieve the effect of periodically conducting the circuit of the electric control valve 20, so that the liquid nitrogen device 1 intermittently ejects nitrogen through the electric control valve 20. Since various temperature monitoring mechanisms generally have a delay, this method is compared with a continuous Nitrogen is sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com