Precast reinforced concrete with enhanced plasticity

A reinforced concrete and reinforced plastic technology, applied in building components, building materials, earthquake-proof and other directions, can solve problems such as cracks, poor crack resistance, rust and corrosion of steel bars, and achieve the effect of improving skew and reducing internal expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

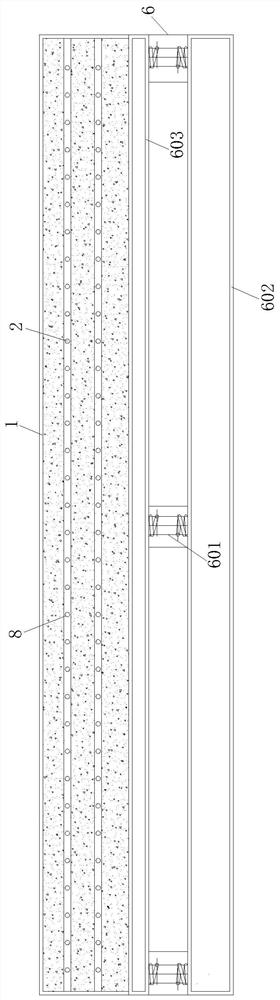

[0033]As an embodiment of the present invention, the shockproof mechanism 6 includes a shockproof plate 602, and a spring 601 is arranged on the top of the shockproof plate 602, and a spring plate 603 is connected above the spring 601; 601 and anti-vibration plate 602 form an elastic telescopic structure, and the spring plate 603 is flexibly connected to the prefabricated plate 1; As a result, the prefabricated panel 1 cracks on the road, and the spring 601 can play a role in damping the shock. In the past, when workers placed the prefabricated panel 1 directly on the transport vehicle, they had to be handled with care to avoid collisions that would cause the prefabricated panel 1 to crack.

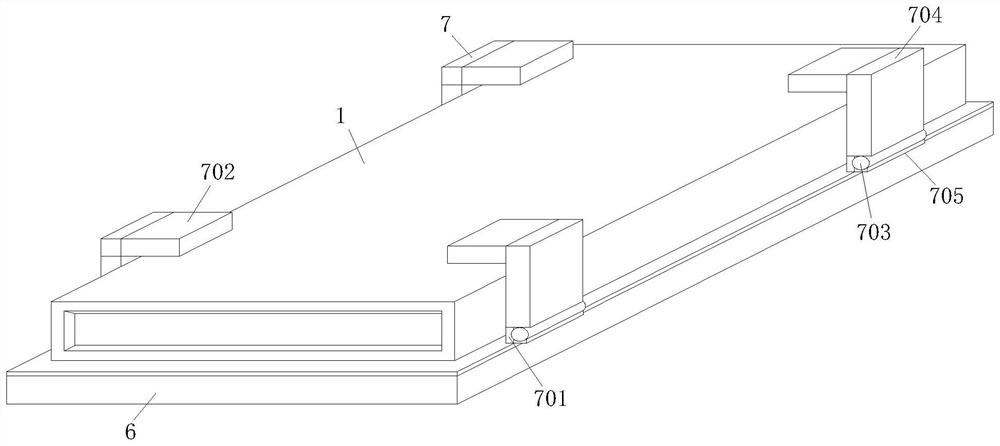

[0034] As an embodiment of the present invention, the fixing mechanism 7 includes a second groove 701, and one end of the second groove 701 is connected with a sliding groove 705, and the top end of the sliding groove 705 is embedded with a rotating shaft 703, and One side of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com