Method for improving dye-uptake of direct dyes on cotton fabrics

A direct technology for cotton fabrics, which is applied in the field of improving the dyeing rate of direct dyes on cotton fabrics, can solve the problems of external water environment pollution, strong toxicity, health threats to operators, etc., and achieves improved K/S value, low cost, and reduced Effects of Environmental Pollution and Harm on Human Body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

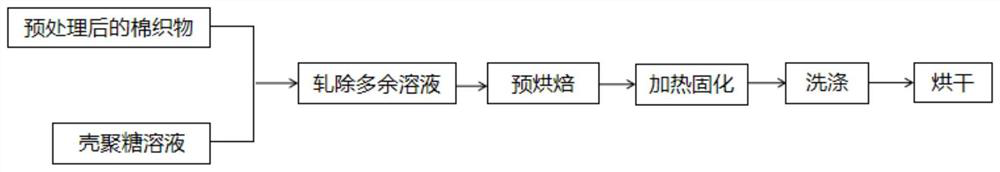

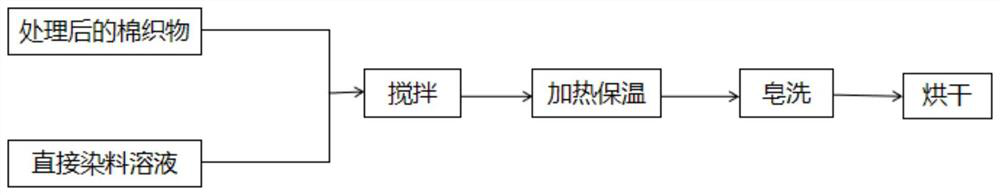

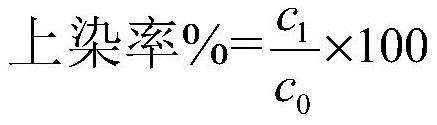

Method used

Image

Examples

Embodiment 1

[0053] (1) The cotton fabric after bleaching and scouring is completely submerged in a citric acid solution with a solvent of 40g / L and a chitosan solution with a concentration of 12g / L, and then the excess solution is removed to control the amount of liquid carried on the cotton fabric 100% by weight, pre-baking at a temperature of 70°C for 2 minutes, and then heating and curing at a temperature of 180°C for 60s;

[0054] (2) Washing the solidified cotton fabric in step (1) in a sodium citrate solution with a concentration of 35g / L, followed by drying;

[0055] (3) After placing the treated cotton fabric obtained in step (2) in a dye solution of sodium copper chlorophyllin (sodium copper chlorophyllin consumption is 1% o.w.f., and the pH value of the solution is 6.4) and stirred for 15 min, the mixture was stirred at a temperature of 5° C. / min. The heating rate is raised from room temperature to 95°C, and the temperature is kept at a constant temperature for 1 hour, and the t...

Embodiment 2

[0058] Implement according to the method described in Example 1, the difference is that in step (1), the concentration of the chitosan solution is 11g / L, to obtain dyed cotton fabric sample A2.

Embodiment 3

[0060] Carried out according to the method described in Example 1, the difference is that in step (1), the liquid carrying amount of the cotton fabric was controlled to be 105% by weight to obtain dyed cotton fabric sample A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com