Adjustable foot and washing machine

A washing machine and bottom adjustment technology, which is applied in the field of washing machines, can solve the problems of small number of screw holes, low precision of tapping machine, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

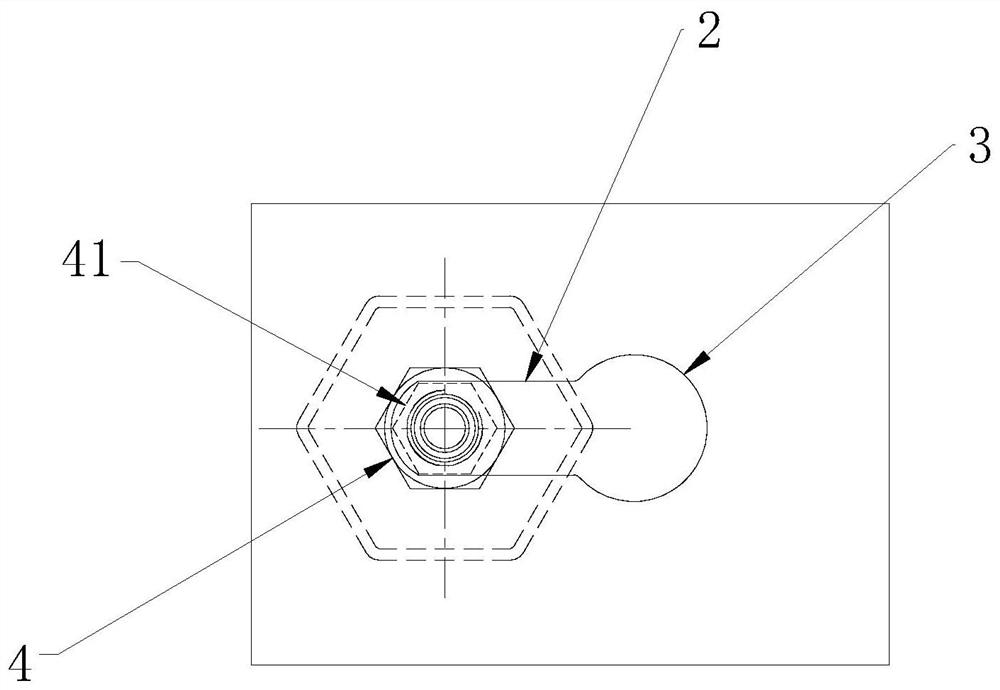

[0041] like image 3 and Figure 4 As shown, this embodiment provides an adjustable foot, including: a support base 7; a bolt 8, one end of which is fixedly connected to the support base 7; an adjusting nut 4, which is threadedly connected to the bolt 8, the adjustment nut 4 is used to adjust the support height of the adjustable foot; the lock nut 5, the lock nut 5 is located on the bolt 8 between the adjustment nut 4 and the support seat 7, through locking The frictional force between the nut 5 and the bolt 8 is used to realize the self-locking of the bolt 8 and ensure the height adjustability of the foot bolt 8 . In the present invention, both the foot bolt 8 and the adjustment nut 4 are standard parts, which have good matching accuracy, can increase the assembly efficiency of the adjustable foot, and reduce the difficulty of assembly. The adjustment nut 4 provided in this embodiment is provided with a The positioning structure for the assembly of the washing machine is di...

Embodiment 2

[0044] This embodiment provides a washing machine. The bottom plate of the washing machine is provided with the adjustable foot according to the present invention, which is used for adjusting the height of the washing machine.

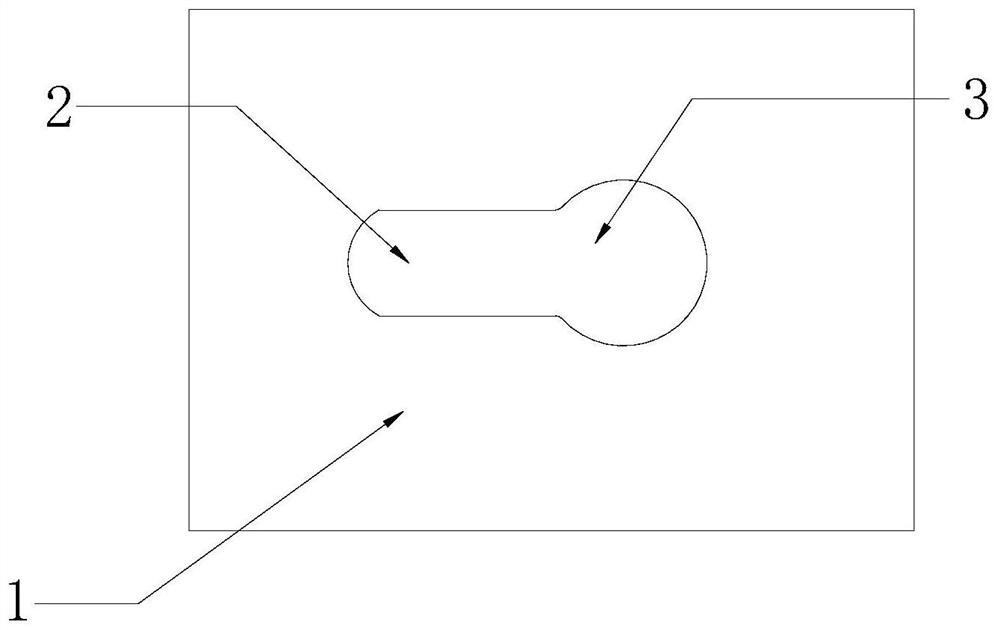

[0045] like Figure 1 to Figure 4 As shown, in this embodiment, the washing machine includes a washing machine bottom plate 1, and a locking hole 2 is opened on the washing machine bottom plate 1 through a stamping process, and the adjusting nut 4 is snapped into the locking hole 2 to realize an adjustable bottom. Assembling of the feet and the washing machine, the assembly of the feet and the washing machine in the prior art is mostly to provide threaded holes on the bottom plate of the washing machine through a tapping machine, and realize the assembly of the washing machine and the feet through the bolts and threaded holes. The bit hole 2 replaces the threaded hole, and realizes the assembly of the foot and the washing machine by means of clamping, ...

Embodiment 3

[0050] In this embodiment, on the basis of the second embodiment, a relief hole communicating with the locking hole is opened on the bottom plate of the washing machine 1, and the adjusting nut can enter into the locking hole through the relief hole.

[0051] Specifically, such as Figure 5 and Figure 6 As shown, a relief hole 3 communicating with the clamping hole 2 is provided on the bottom plate of the washing machine through a stamping process. The relief hole 3 is a circular hole in the cross section of the external adjustment nut 4. The circular hole The aperture is greater than the distance of the longest diagonal line of the adjusting nut 4, so as to ensure that the adjusting nut 4 can freely pass through the relief hole 3, and can be moved and embedded in the locking hole 2 through the relief hole 3. Through the relief hole 3 provided, the adjusting nut 4 can enter the locking hole 2 from the relief hole 3, and does not need to enter the locking hole 2 from the gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com