Antibacterial halogen-free flame retardant reinforced PE/PET composite staple fiber and preparation method thereof

A short fiber and flame retardant technology, which is applied in the field of antibacterial, halogen-free and flame retardant reinforced PE/PET composite short fiber and its preparation, can solve the problems of poor compatibility of composite fibers, no bactericidal function of composite fibers, and composite fiber resistance. Poor combustion performance and other problems, to achieve the effect of solving interface wettability and compatibility problems, excellent physical properties, and high flame retardant level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

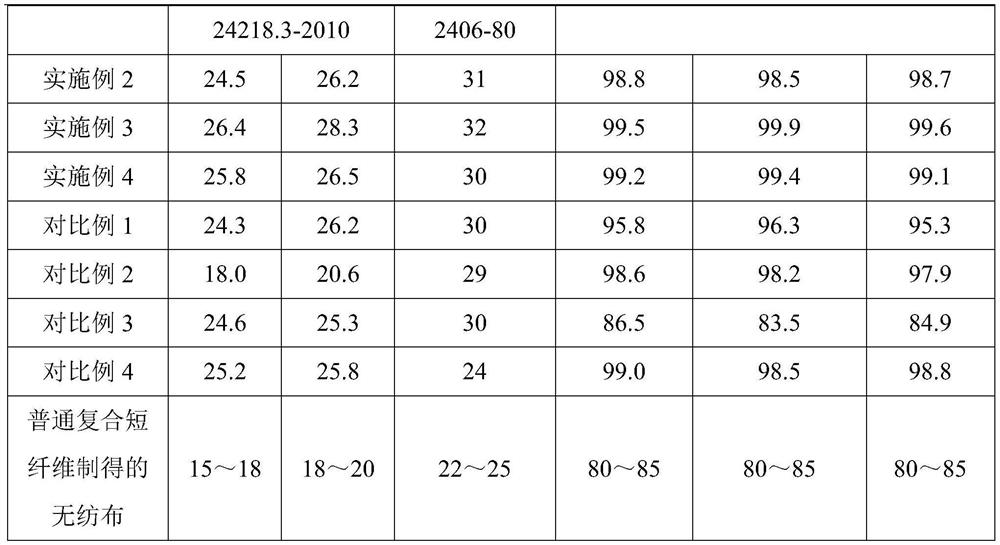

Examples

Embodiment 1

[0038] An antibacterial, halogen-free, flame-retardant reinforced grade PE / PET composite short fiber, which is composed of the following raw materials in parts by weight: 30-50 parts of PE, 35-50 parts of PET, 8-15 parts of graphene, and 10-18 parts of modified carbon nanofibers 8-15 parts of compound antibacterial agent, 6-10 parts of halogen-free flame retardant, 5-10 parts of toughening agent, 3-8 parts of compatibilizer, 2-5 parts of antioxidant and 0.1-10 parts of other additives 2.5 servings.

[0039] In this embodiment, the intrinsic viscosity of the PE is 0.7-1.1 dl / g, and the intrinsic viscosity of the PET is 0.5-1.2 dl / g.

[0040] In this embodiment, the composite antibacterial agent is a compound composed of an inorganic antibacterial material and an organic antibacterial material in a mass ratio (2 to 3): 1; wherein, the inorganic antibacterial material is a mixture of nano silver and nano titanium dioxide. Compound, the particle size of nano-silver is 5-15nm, the...

Embodiment 2

[0056] An antibacterial, halogen-free, flame-retardant reinforced grade PE / PET composite short fiber, which consists of the following raw materials in parts by weight: 30 parts of PE, 40 parts of PET, 8 parts of graphene, 10 parts of modified nano-carbon fiber, 15 parts of composite antibacterial agent, 8 parts of halogen-free flame retardant, 8 parts of toughening agent, 5 parts of compatibilizer, 3 parts of antioxidant and 0.3 parts of other additives.

[0057] In this embodiment, the intrinsic viscosity of the PE is 0.7dl / g, and the intrinsic viscosity of the PET is 0.5dl / g.

[0058] In this embodiment, the composite antibacterial agent is a compound composed of an inorganic antibacterial material and an organic antibacterial material at a mass ratio of 2:1; wherein the inorganic antibacterial material is a compound of nano-silver and nano-titanium dioxide, The particle size of the nano-silver is 8nm, and the particle size of the nano-titanium dioxide is 15nm; the organic a...

Embodiment 3

[0074] An antibacterial, halogen-free, flame-retardant reinforced grade PE / PET composite short fiber, consisting of the following raw materials in parts by weight: 40 parts of PE, 38 parts of PET, 10 parts of graphene, 12 parts of modified nano-carbon fiber, 10 parts of composite antibacterial agent, 8 parts of halogen-free flame retardant, 6 parts of toughening agent, 5 parts of compatibilizer, 2 parts of antioxidant and 1.5 parts of other additives.

[0075] In this embodiment, the intrinsic viscosity of the PE is 1.0dl / g, and the intrinsic viscosity of the PET is 0.8dl / g.

[0076] In this embodiment, the composite antibacterial agent is a compound composed of an inorganic antibacterial material and an organic antibacterial material at a mass ratio of 2.5:1; wherein the inorganic antibacterial material is a compound of nano-silver and nano-titanium dioxide, The particle size of the nano-silver is 10nm, and the particle size of the nano-titanium dioxide is 25nm; the organic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com