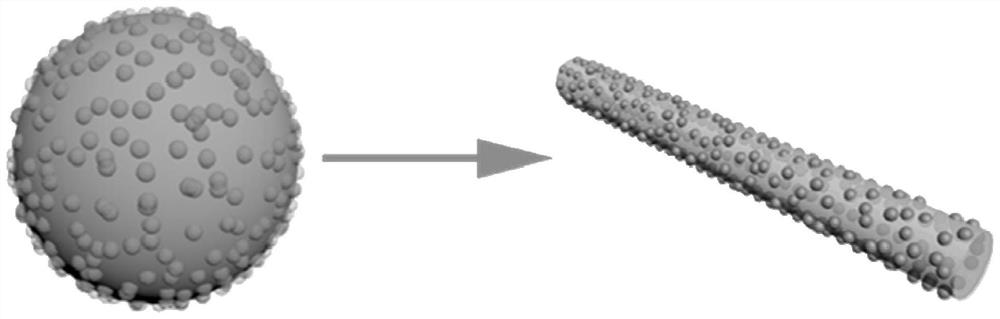

Preparation method of strawberry-shaped organic/inorganic crosslinked microsphere orientation filling enhanced chemical fibers

An inorganic cross-linking and organic technology, applied in the field of reinforced chemical fibers, can solve the problems of material defects, poor compatibility, weak interfacial force and other problems, and achieve the effects of less mechanical defects, uniform dispersion and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0078] (1) Take 100 mL of glacial acetic acid solution with a pH value of about 4 in a four-necked flask, add 0.4 mL of MPS, and pre-hydrolyze for 5 min in an ice-water bath at a stirring speed of 150 rpm.

[0079] (2) Add ammonia water to the pre-hydrolyzed solution in step (1) to adjust the pH value of the mixed solution to about 7.

[0080] (3) Take St and BA according to the proportions shown in Examples 1-3 in Table 1 and mix evenly, weigh 0.05g AIBN and dissolve it in the monomers taken. After the monomer is added to the mixture in (2), adjust the stirring speed to 200rpm, and maintain the emulsification under the condition of ice-water bath (100w) for 60min.

[0081] (4) Get 20mL of SiO with a content of 1wt% and a particle size of 30nm 2 Mix the dispersion liquid with 0.6mL triethylamine evenly, and pass through the syringe pump (100mL·h -1 Speed) add step (3) gained emulsion. Sonicate for 30 min in an ice-water bath.

[0082] (5) Nitrogen was passed through the em...

Embodiment 4、5

[0086] (1) Take 0.8-1.2mL MPS in a glacial acetic acid solution with a pH of about 4, and pre-hydrolyze it in an ice-water bath at a stirring speed of 150rpm for 5min.

[0087] (2) Add ammoniacal liquor to the prehydrolyzate obtained in (1) to adjust to neutrality.

[0088] (3) Mix 4gSt, 1gBA and 0.05gAIBN evenly, add to the neutral solution obtained in (2), and emulsify with ultrasound (100w) for 60min in an ice-water bath.

[0089] (4) Through the syringe pump (100mL·h -1 speed) in step (3) in the gained emulsion, adding 20mL content is 1wt%, particle diameter is the SiO of 30nm 2 Dispersion liquid and 0.6mL triethylamine, continue to sonicate for 30min.

[0090] (5) The stable emulsion obtained in (4) was passed through nitrogen to remove oxygen, and then added to initiate free radical polymerization. The polymerization condition was to react at 70° C. for 8 hours. The product was centrifuged and washed with ethanol (centrifugal speed 12000 rpm, centrifugation time 10 mi...

Embodiment 6、7

[0094] (1) Take 0.8mL MPS and pre-hydrolyze it in glacial acetic acid solution for 6-7min. Add ammonia water after pre-hydrolysis to adjust to neutrality.

[0095] (2) Mix 4g St, 1g BA and 0.05g AIBN evenly, add to the neutral solution obtained in (1), and emulsify with ultrasound (100w) for 60min in an ice-water bath.

[0096] (3) Through a syringe pump (100mL·h -1 Speed) Add 20mL of SiO with a content of 1wt% and a particle size of 30nm in the emulsion obtained in step (2). 2 Dispersion liquid and 0.6mL triethylamine, continue to sonicate for 30min.

[0097] (4) The stable emulsion obtained in (3) was passed through nitrogen to exhaust oxygen, and then added to initiate free radical polymerization, and the polymerization condition was to react at 70° C. for 8 hours. The product was centrifuged and washed with ethanol (centrifugal speed 12000 rpm, centrifugation time 10 min) for 3 times and then dried to obtain a white powder.

[0098] (5) After mixing the dried composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com