Heat magnetic adsorption technology based stainless steel oil-removing collecting device

A stainless steel and oil collection technology, applied in the field of stainless steel processing, can solve the problems of not being able to collect oil stains, reducing the utilization rate of oil stains, etc., and achieving the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

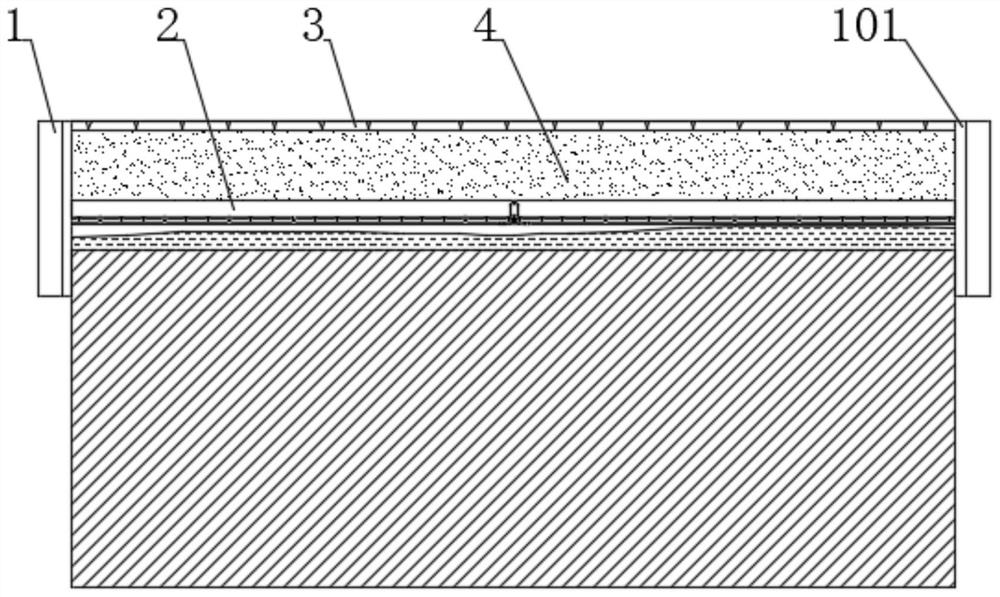

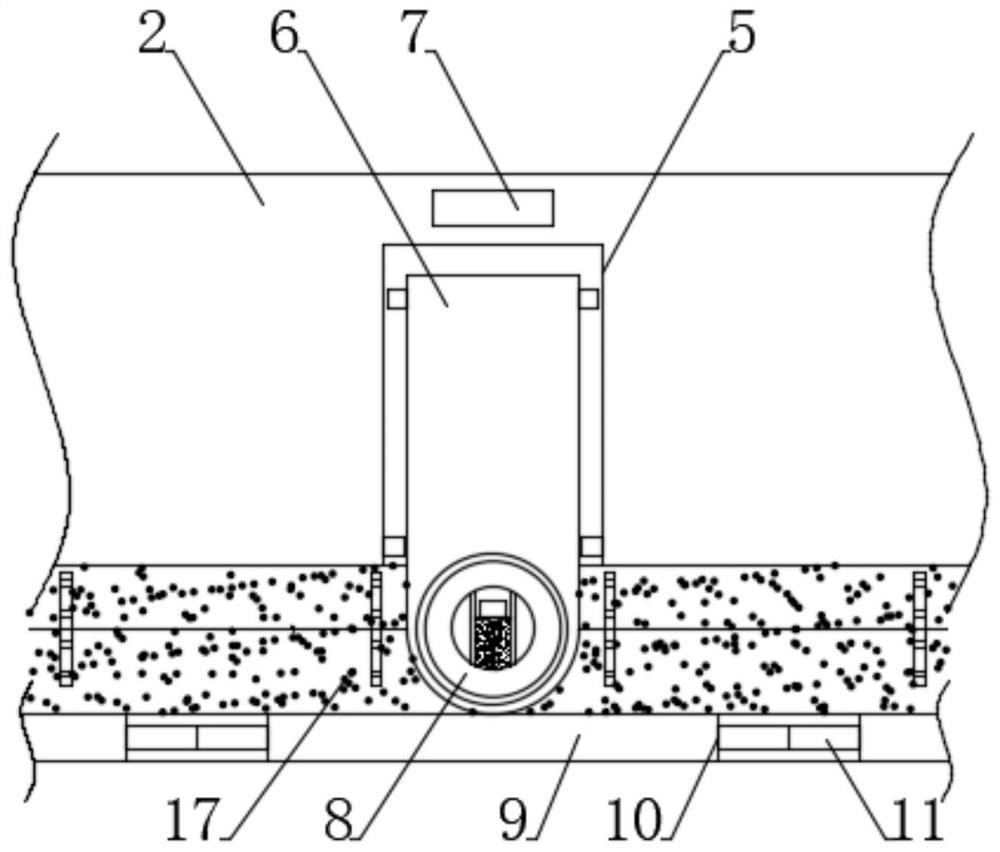

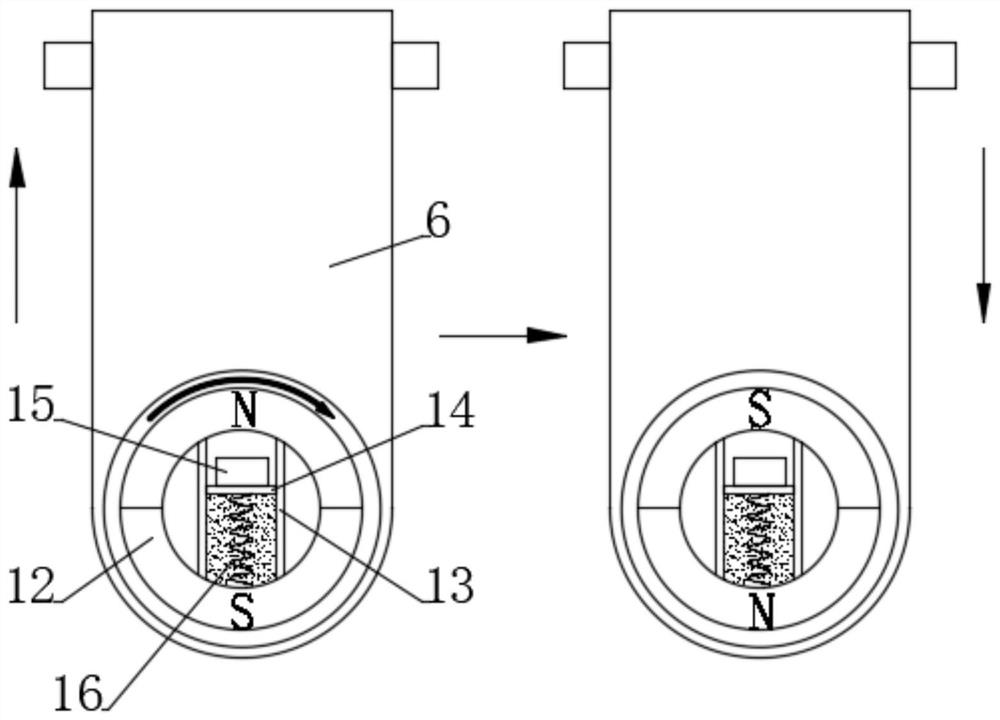

[0042] see Figure 1-3 , a stainless steel oil removal collection device based on thermomagnetic adsorption technology, comprising a collection outsourcing frame 1 sleeved on the outside of the stainless steel plate, the inner wall of the collection outsourcing frame 1 is fixedly connected with a middle partition plate 2 and located on the upper side of the middle partition plate 2 The pre-dissolved film 3 is filled with calcium oxide powder 4 between the middle partition plate 2 and the pre-dissolved film 3. After the oil stain on the surface of the stainless steel plate is absorbed, the calcium hydroxide powder 4 and the calcium hydroxide generated after the reaction can be used. The collection outsourcing frame 1 is turned upside down and covered on the stainless steel plate and slides repeatedly to realize the cleaning of a small amount of oil stain attached to its surface. The bottom of the middle partition plate 2 is dug with a storage groove 5, and a push slide is insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com