Hot melt adhesive for difficult-to-stick base material and preparation method thereof

A technology for hot melt adhesives and substrates, applied in the directions of adhesives, adhesive types, conjugated diene adhesives, etc., which can solve the problems of increasing the complexity of production and failing to meet the requirements of product design and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

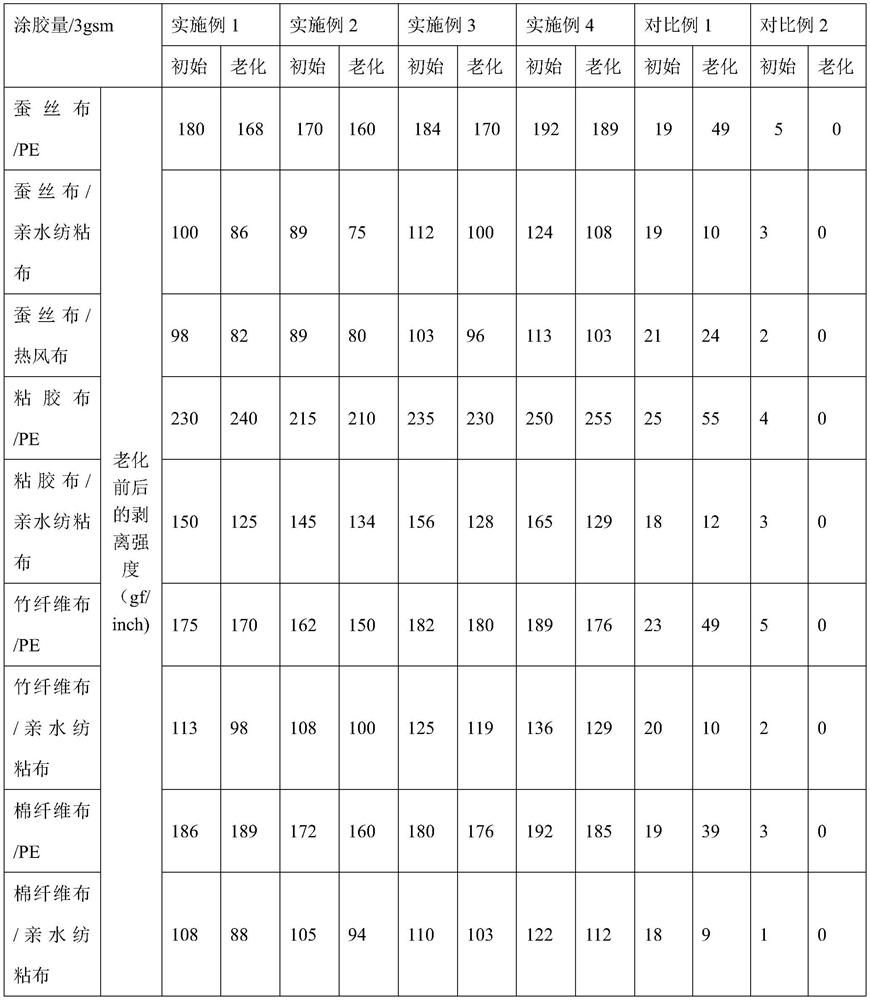

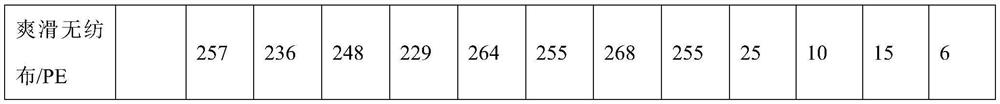

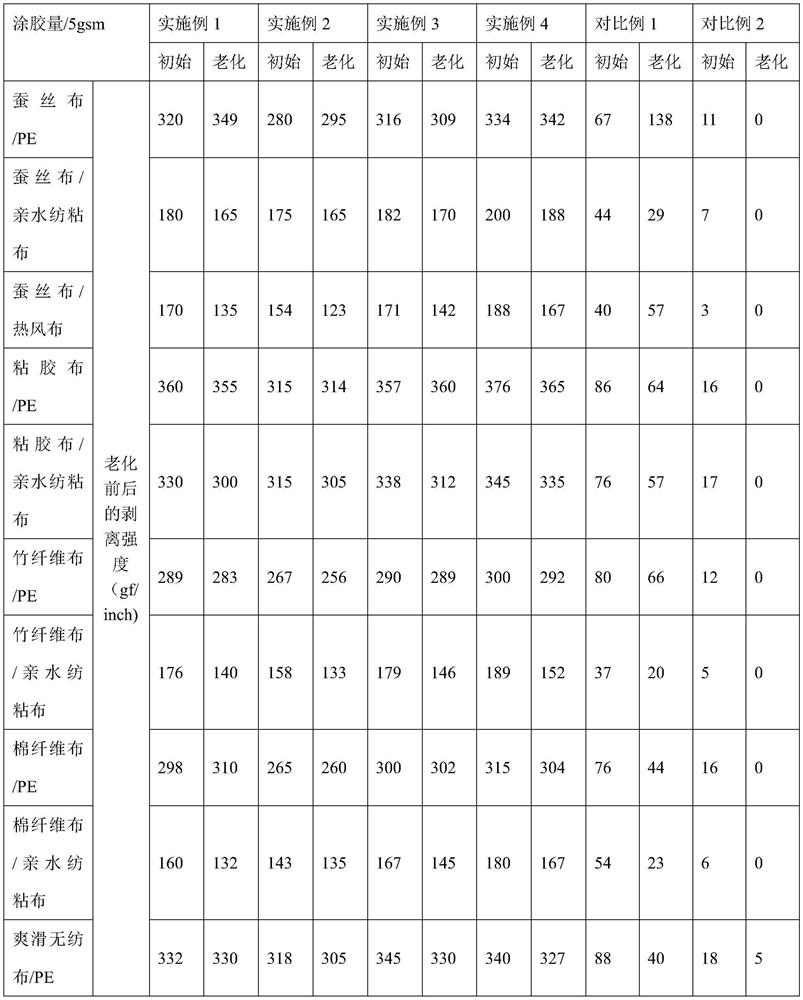

Examples

preparation example Construction

[0039] The second object of the present invention is achieved by the following technical solutions: a method for preparing hot melt adhesive for difficult-to-bond substrates, comprising the following steps:

[0040] (1) Add part of the naphthenic oil of formula quantity and the antioxidant of formula quantity in kneader, and heat up;

[0041] (2) Add the formula amount of styrene-based elastomer and stir. After the mixed system is melted, add the formula amount of styrene-butadiene rubber, continue to stir and melt; after the mixed system is melted, add the formula amount of polyolefin elastomer After stirring and mixing evenly, add the amount of tackifying resin in the formula, and stir evenly for 20 minutes;

[0042] (3) Put in the remaining naphthenic oil and ultraviolet absorber, stir evenly for 20 minutes, vacuumize to remove air bubbles, discharge the material, cool to room temperature, and obtain a hot-melt adhesive for difficult-to-stick substrates.

[0043] As a furt...

Embodiment 1

[0049] The raw materials of hot-melt adhesive for difficult-to-bond substrates are composed according to the following parts by weight: naphthenic oil 47135 15 parts, SIS 110513 parts, SIS 4186 5 parts, solution polystyrene butadiene rubber 1205 7 parts, polyolefin elastomer GA-1000R 5 parts 40 parts of semi-hydrogenated petroleum resin C-100R, 10 parts of semi-hydrogenated rosin resin H120, 2 parts of modified terpene resin T160, 0.6 parts of antioxidant 1010 and 0.6 parts of antioxidant 168, 0.8 parts of antioxidant 4120, UV Absorber UV-326H 1 part.

Embodiment 2

[0051] The raw materials of the hot melt adhesive for difficult-to-bond substrates are composed of the following parts by weight: 30 parts of naphthenic oil 47135, SIS 110530 parts, 10 parts of solution polystyrene butadiene rubber 2605, 10 parts of polyolefin elastomer GA-1000R, semi-hydrogenated petroleum 16.7 parts of resin C-100R, 2 parts of modified terpene resin, 0.1 parts of antioxidant 1010 and 168, 0.1 part of antioxidant FT-1126, 1 part of ultraviolet absorber UV-326H.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com