Antiviral coating and preparation method thereof

An anti-virus and paint technology, applied in the field of paint, can solve the problems of difficulty in having anti-virus effect, poor anti-virus effect, and difficulty in adapting to various application places, so as to reduce the probability of being oxidized, the method is simple, and the anti-virus effect is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

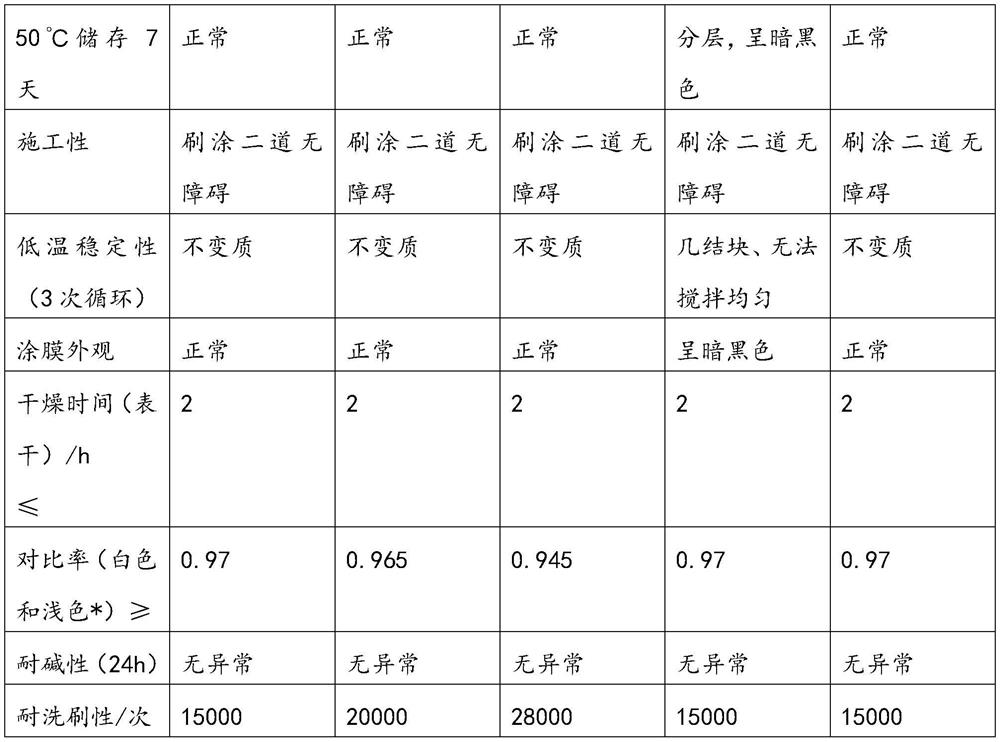

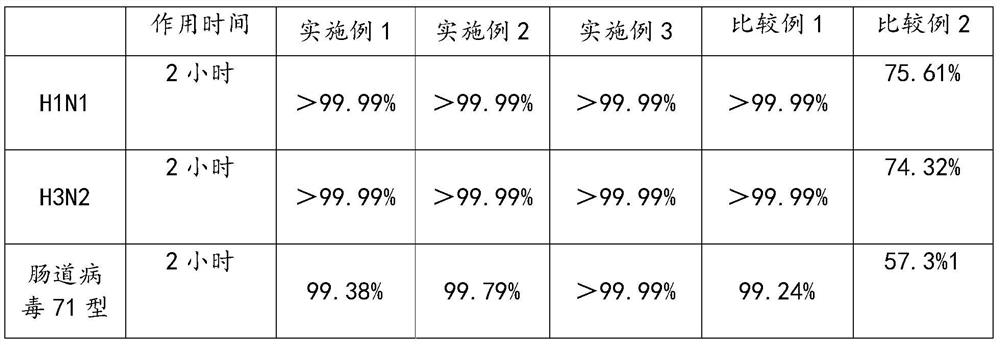

Embodiment 1

[0037] A kind of antiviral paint, proportioning according to parts by weight:

[0038] 18.9 parts of deionized water, 0.5 parts of cuprous oxide, 25 parts of EVA / acid-acrylic aqueous emulsion, 1 part of wetting agent, 1.2 parts of dispersing agent, 0.5 parts of defoaming agent, 0.5 parts of film-forming aid, 0.4 parts of thickener , 25 parts of pigment, 25 parts of filler and 2 parts of diatomaceous earth.

[0039] The preparation method of above-mentioned antiviral coating is as follows:

[0040] S1: Add 5 parts of deionized water into the reaction tank A, stir at a speed of 100 rpm, slowly add cuprous oxide, continue stirring for 5 minutes, use 0.05mol / L HCl, adjust the pH value to 5; set aside for later use;

[0041] S2: Add the remaining 13.9 parts of deionized water, thickener, wetting agent, dispersant and defoamer to reaction tank B, and stir at a speed of 500 rpm for 10 minutes;

[0042] S3: Put the pigment, filler and diatomaceous earth into the reaction tank B in t...

Embodiment 2

[0046] A kind of antiviral paint, proportioning according to parts by weight:

[0047] 21.2 parts of deionized water, 1 part of cuprous oxide, 30 parts of EVA / acid-acrylic aqueous emulsion, 0.6 parts of wetting agent, 0.8 parts of dispersing agent, 0.8 parts of defoaming agent, 1 part of film-forming aid, and 0.6 parts of thickener , 21 parts of pigment, 20 parts of filler and 3 parts of diatomaceous earth.

[0048] The preparation method of above-mentioned antiviral coating is as follows:

[0049] S1: Add 5 parts of deionized water into the reaction tank A, stir at a speed of 100 rpm, slowly add cuprous oxide, continue stirring for 5 minutes, use 0.05mol / L HCl, adjust the pH value to 6; set aside for later use;

[0050] S2: Add the remaining 16.2 parts of deionized water, thickener, wetting agent, dispersant and defoamer to reaction tank B, and stir at a speed of 500 rpm for 10 minutes;

[0051] S3: Put the pigment, filler and diatomaceous earth into the reaction tank B in ...

Embodiment 3

[0055] A kind of antiviral paint, proportioning according to parts by weight:

[0056] 22.4 parts of deionized water, 1.5 parts of cuprous oxide, 35 parts of EVA / acrylic acid aqueous emulsion, 0.3 parts of wetting agent, 0.5 parts of dispersing agent, 1 part of defoamer, 1.5 parts of film-forming aid, 0.8 parts of thickener , 17 parts of pigment, 15 parts of filler and 5 parts of diatomaceous earth.

[0057] The preparation method of above-mentioned antiviral coating is as follows:

[0058] S1: Add 5 parts of deionized water into the reaction tank A, stir at a speed of 100 rpm, slowly add cuprous oxide, continue stirring for 5 minutes, use 0.05mol / L HCl, adjust the pH value to 5; set aside for later use;

[0059] S2: Add the remaining 17.4 parts of deionized water, thickener, wetting agent, dispersant and defoamer to reaction tank B, and stir at a speed of 500 rpm for 10 minutes;

[0060] S3: Put the pigment, filler and diatomaceous earth into the reaction tank B in turn, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com