Modified polyether, composite crude oil demulsifier, and preparation method and application of composite crude oil demulsifier

A crude oil demulsifier and polyether technology, applied in the field of composite crude oil demulsifier and modified polyether, can solve the problems of lower dehydration temperature, high thermal energy consumption, and increased viscosity of emulsified crude oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

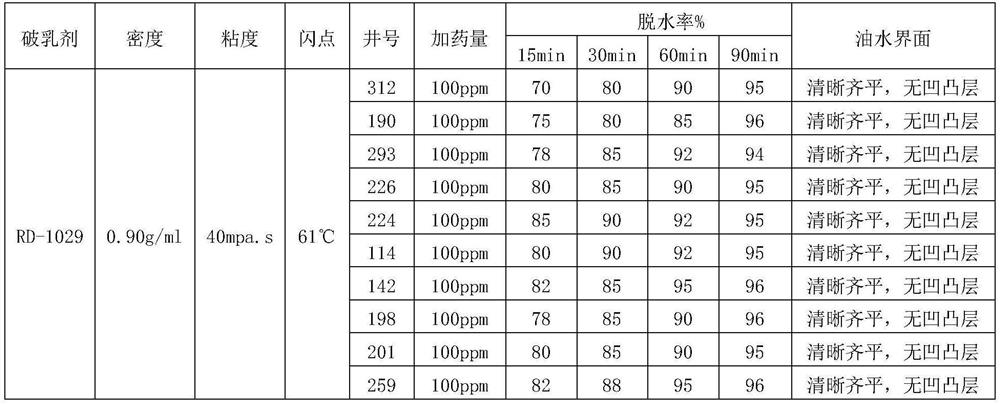

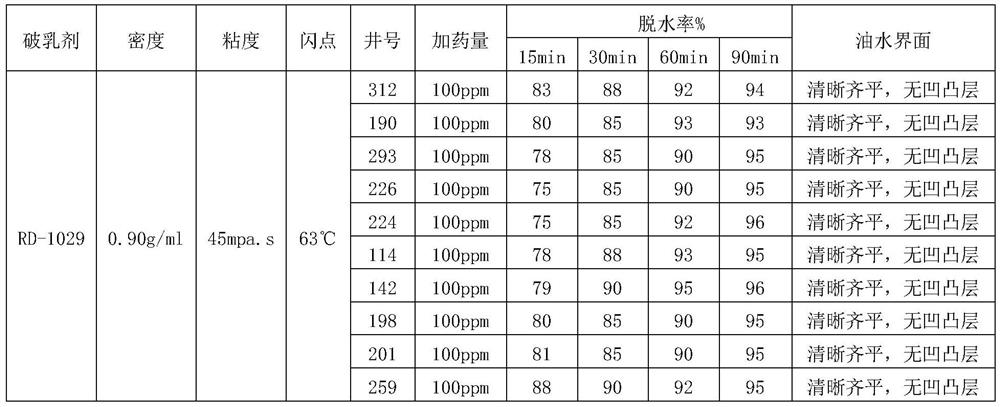

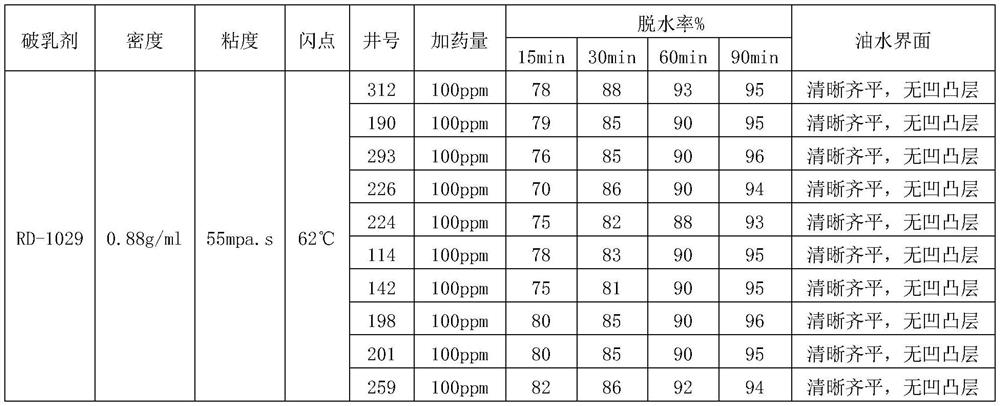

Examples

preparation example Construction

[0043] The invention provides a kind of preparation method of modified polyether, comprises the following steps:

[0044] a Preheat the phenolic compound and vinylamine compound under normal pressure at 50-70°C for 30-50min; 2 Or raise the temperature to 110-130°C within 30min-60min under an inert atmosphere, then add formaldehyde solution dropwise, raise the pressure to 0.2-0.6MPa, and react at a constant temperature of 110-130°C for 2-5 hours to obtain the first intermediate product;

[0045] b Add alkali to the first intermediate product, add an aqueous solution of epoxy alkyl compound dropwise at 0.2-0.6MPa, 110-130°C, react at constant temperature and pressure for 5-7 hours, then cool to 70-90°C to obtain the first two intermediate products;

[0046] c. The second intermediate product is decompressed to normal pressure, cooled to room temperature, and after neutralization and purification, the modified polyether is obtained;

[0047] The cloud point of the modified poly...

Embodiment 1

[0074] Weigh p-cresol and diethylenetriamine respectively according to the mass ratio of 4:1, add up to 100g, pour them into a sealed 1L 304 stainless steel reaction tank, preheat at 60°C for 30min under normal pressure; use N2 or inert The gas replaces the air in the tank, and the replacement time is 30 minutes; then the stirring is started, the stirring rate is kept at 200 rpm / min, and the temperature is raised to 130° C. within 30 minutes. Then slowly drop 5g of formaldehyde solution with a concentration of 30wt%, and control the rate of dropping to 30 drops / min, the pressure in the tank rose to 0.4MPa, the reaction temperature was 130°C, and the reaction was performed at a constant temperature for 2 hours. Add the solid sodium hydroxide of 1.65g then, tank internal pressure remains on 0.4MPa, and temperature is constant at 130 ℃, dripping 10g concentration is the ethylene oxide aqueous solution of 99wt% and 10g concentration is the propylene oxide aqueous solution of 99wt%,...

Embodiment 2

[0097] Weigh phenol and diethylenetriamine respectively according to the mass ratio of 4:1, the total of the two is 50g, pour it into a sealed 1L 304 stainless steel reaction tank, preheat at 50°C for 30min under normal pressure; use N2 or inert gas to replace the tank Inner air, the replacement time is 30min; then start stirring, the stirring rate is kept at 200rpm / min, and the temperature is raised to 125°C within 30min. Then slowly drip 5g of formaldehyde solution with a concentration of 30wt%, control the rate of addition at 30 drops / min, the pressure in the tank rises to 0.4MPa, the reaction temperature is 125°C, and the reaction is performed at a constant temperature for 4 hours. Add the solid sodium hydroxide of 2g then, tank inner pressure remains on 0.4MPa, and temperature is constant at 125 ℃, drips 20g concentration and is the aqueous solution of ethylene oxide of 99wt%, the rate of addition of aqueous solution of control ethylene oxide is 20 drop / min, after 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com