A kind of composite microcapsule, preparation method and application thereof

A composite microcapsule and reaction technology, which is applied in the field of self-repairing micro-cracks of shotcrete materials in coal mines, can solve problems such as affecting the strength and durability of concrete materials, destroying the structural integrity of matrix materials, and being difficult to repair internally, and achieves effective control of polycondensation. The effect of response speed, self-healing, and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

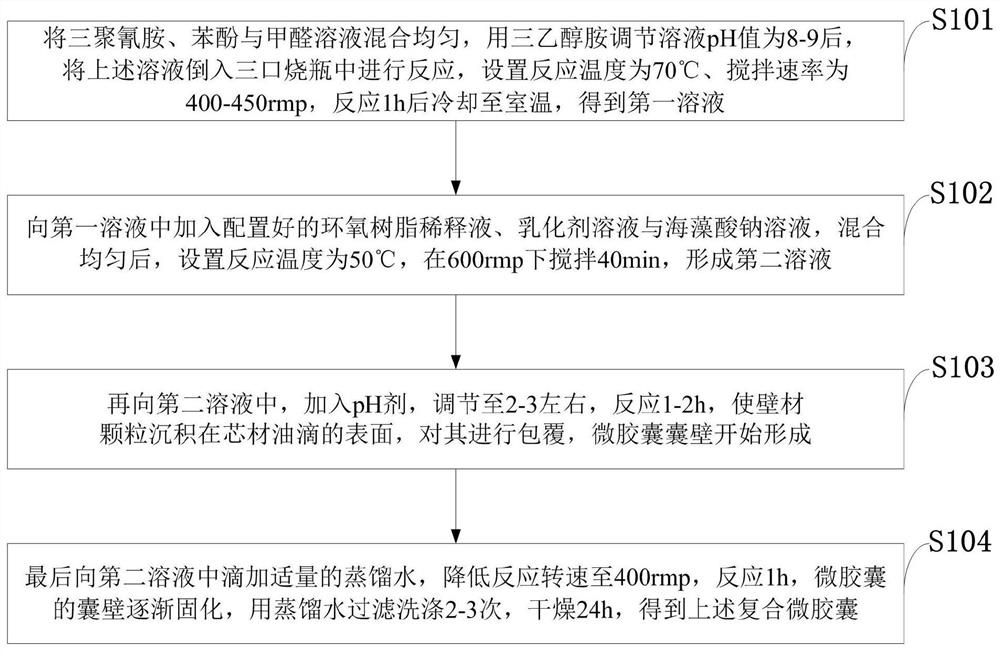

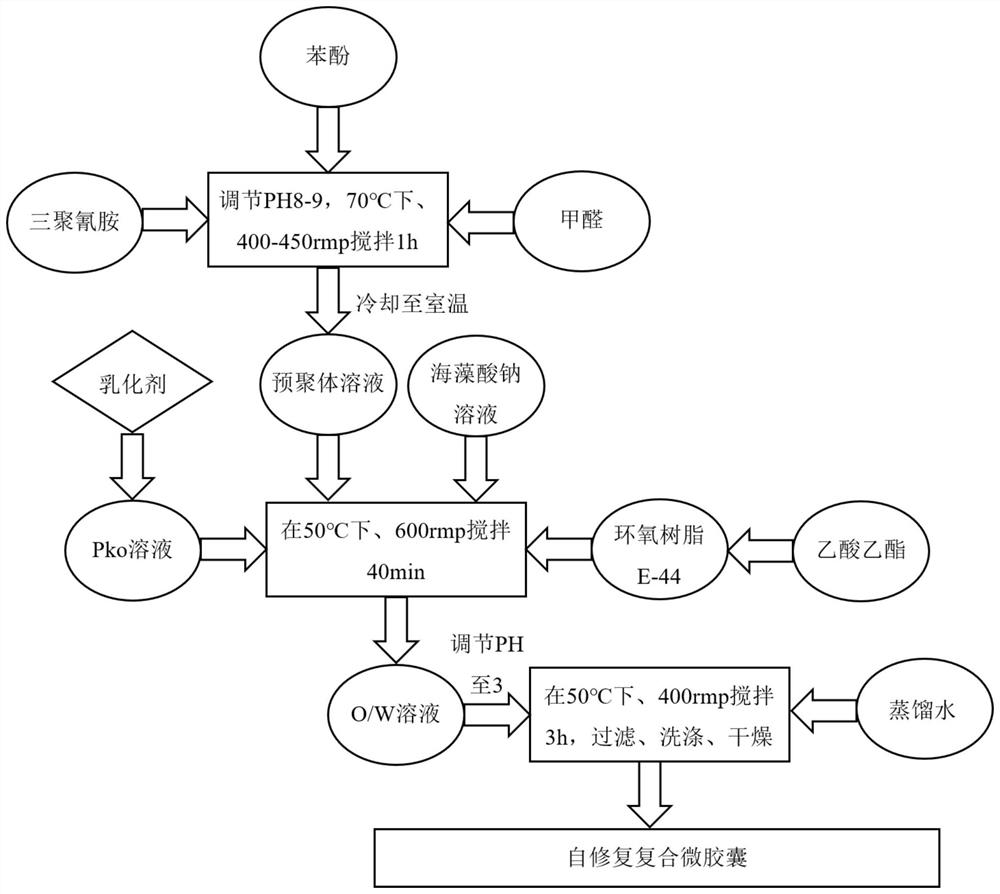

[0037] Such as figure 1Shown, the preparation method of composite microcapsule provided by the invention may further comprise the steps:

[0038] S101: Mix melamine, phenol and formaldehyde solution evenly, adjust the pH value of the solution to 8-9 with triethanolamine, pour the above solution into a three-necked flask for reaction, set the reaction temperature to 70°C, and the stirring rate to 400-450rmp, After reacting for 1 h, cool to room temperature to obtain the first solution;

[0039] S102: Add the prepared epoxy resin diluent, emulsifier solution and sodium alginate solution to the first solution, mix evenly, set the reaction temperature to 50°C, and stir at 600rmp for 40min to form the second solution;

[0040] S103: Add a pH agent to the second solution, adjust it to about 2-3, and react for 1-2 hours, so that the wall material particles are deposited on the surface of the core material oil droplet and coated, and the microcapsule wall begins to form ;

[0041] ...

Embodiment 1

[0049] The preparation method of the composite microcapsules provided by the present invention weighs 6g of melamine, 16g of phenol and 26.4g of formaldehyde solution in a beaker and mixes them uniformly. After stirring for 1 h, it was cooled to room temperature to obtain a prepolymer solution. Weigh 40g of epoxy resin and 6g of ethyl acetate in a beaker and stir evenly, then add to the prepolymer solution, then add 1g of emulsifier solution and 6g of sodium alginate solution to the solution, at 50°C, at 600rmp Stir for 40 min to form an O / W solution. Adjust the pH of the O / W solution to about 2-3 with dilute sulfuric acid, react for 1-2 hours, and the microcapsule wall begins to form. Add an appropriate amount of distilled water dropwise, keep the reaction temperature constant, reduce the reaction speed to 400rmp, react for 1h, and the capsule walls of the microcapsules are gradually solidified. Filter and wash with distilled water for 2-3 times, and dry in a vacuum oven at...

Embodiment 2

[0051] The preparation method of the composite microcapsules provided by the present invention weighs 6g of melamine, 16g of phenol and 26.4g of formaldehyde solution in a beaker and mixes them uniformly. After stirring for 1 h, it was cooled to room temperature to obtain a prepolymer solution. Weigh 40g of epoxy resin and 7g of ethyl acetate in a beaker and stir evenly, then add to the prepolymer solution, then add 1g of emulsifier solution and 6g of sodium alginate solution to the solution, at 50°C, at 600rmp Stir for 40 min to form an O / W solution. Adjust the pH of the O / W solution to about 2-3 with dilute sulfuric acid, react for 1-2 hours, and the microcapsule wall begins to form. Add an appropriate amount of distilled water dropwise, keep the reaction temperature constant, reduce the reaction speed to 400rmp, react for 1h, and the capsule walls of the microcapsules are gradually solidified. Filter and wash with distilled water for 2-3 times, and dry in a vacuum oven at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com