Zero-emission process method for treating and recycling comprehensive wastewater in iron and steel industry

A technology that integrates wastewater and iron and steel industries. It is used in metallurgical wastewater treatment, water/sewage treatment, and aerobic process treatment. It can solve problems such as unstable operation, shortened membrane cleaning cycles, and substandard water quality indicators. Reuse rate, significant environmental and economic benefits, and the effect of saving enterprise investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

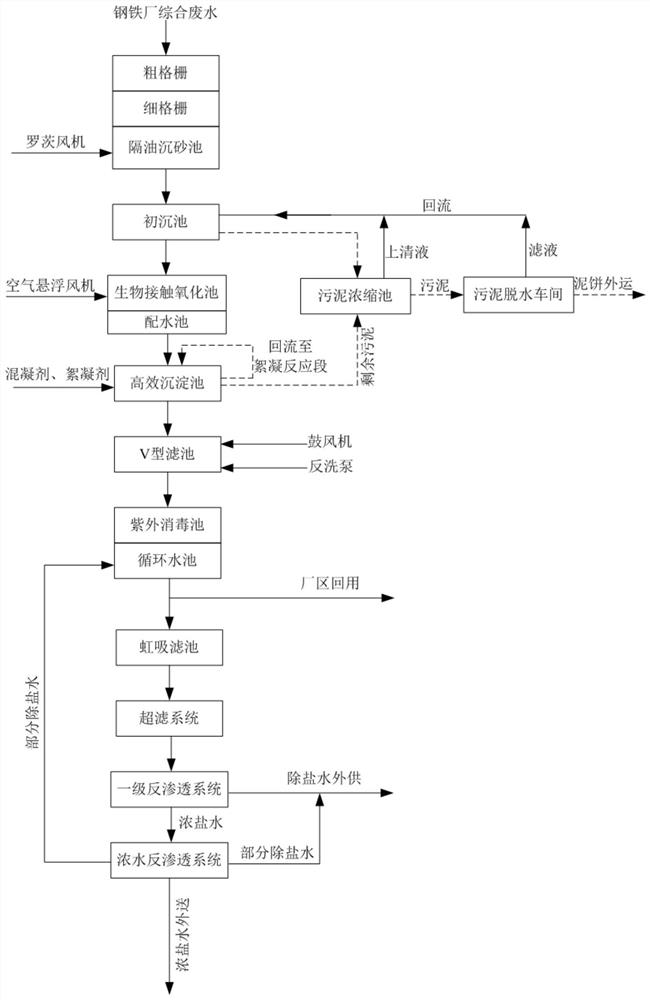

[0018] Such as figure 1 Shown, the present invention a kind of processing method of iron and steel industry comprehensive waste water treatment reuse zero discharge, it is characterized in that carry out by the following steps:

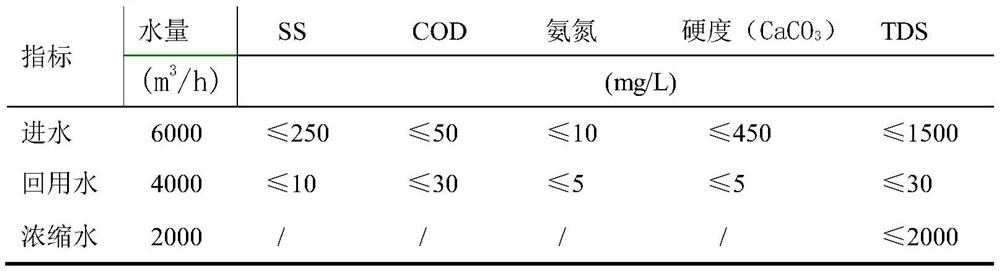

[0019] The comprehensive wastewater from the iron and steel plant intercepts floating objects and impurities through the coarse screen and the fine screen, and then flows into the oil-separating grit chamber by gravity, removes slick oil and large particles of sand in the oil-separating grit chamber, and then enters the primary sedimentation tank by gravity; the comprehensive wastewater After entering the primary sedimentation tank, the sedimentable and suspended solids are further removed, the water quality is homogenized, and the impact of water quality changes on the subsequent biochemical system is slowed down, and then gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com