Cadmium sulfide nanorod and method for friction catalytic degradation of organic pollutants

A technology of cadmium sulfide nanorods and organic pollutants, applied in the direction of cadmium sulfide, water pollutants, chemical instruments and methods, etc., can solve the problems of surrounding environmental hazards, reduce degradation costs, be suitable for popularization and application, and avoid equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

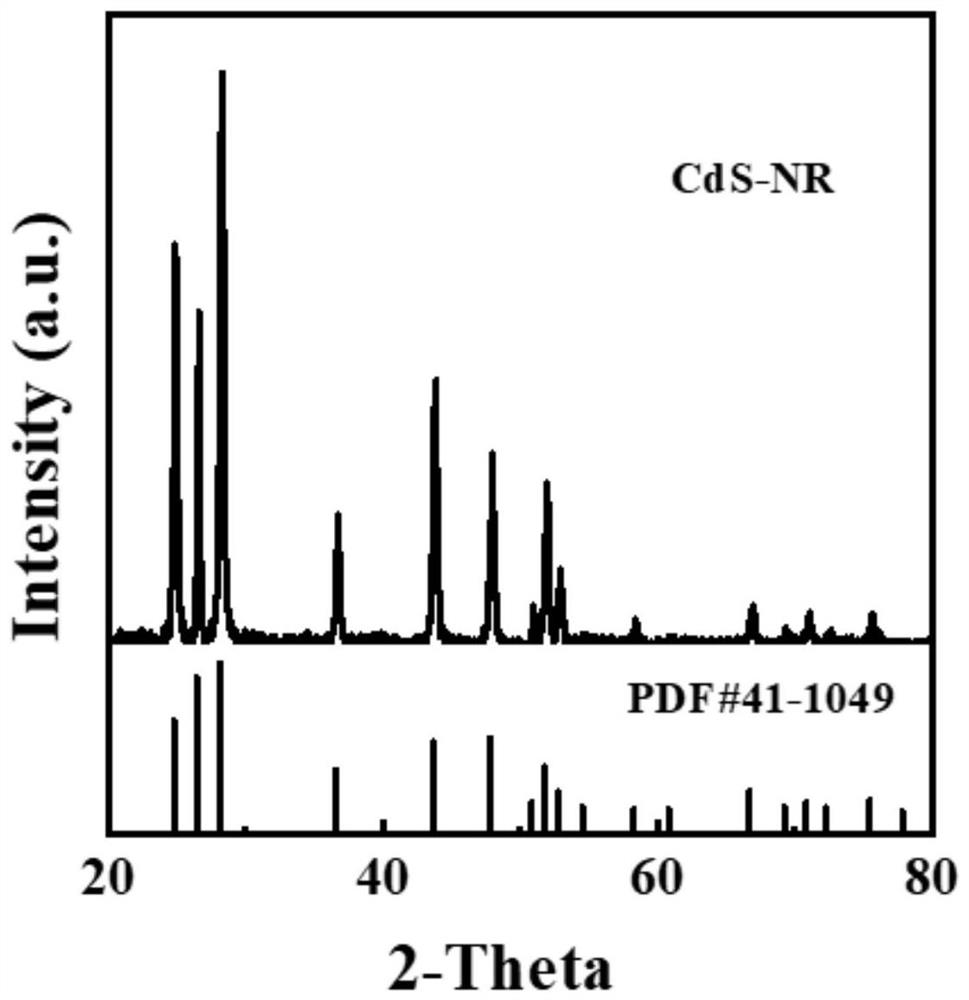

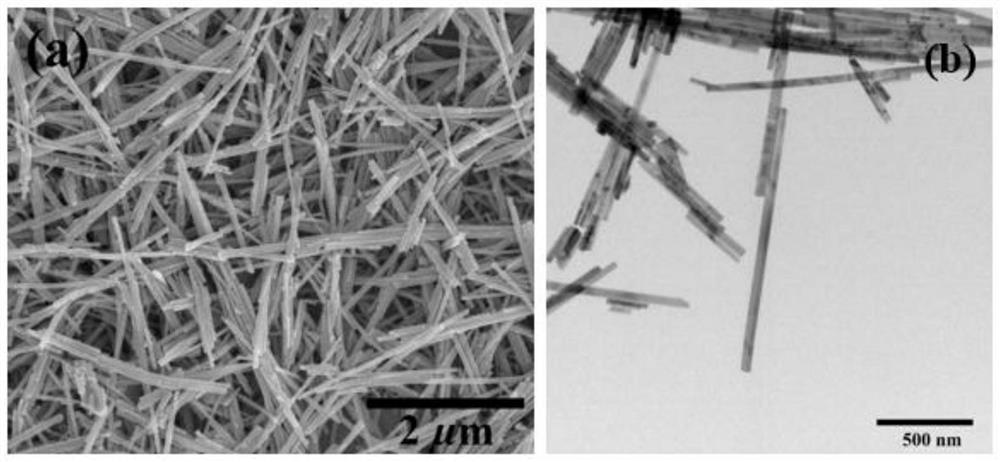

[0028] The preparation method of the cadmium sulfide nanorod includes the following steps:

[0029] In the first step, disperse chromium nitrate tetrahydrate and thiourea in a 0.86mol / L ethylenediamine solution, stir evenly and transfer to the reactor, and keep the reaction at 135~178℃ for 15-75h, and the resulting product is washed , The hybrid precursor is obtained after drying;

[0030] In the second step, the hybrid precursor is dispersed in deionized water, ultrasonically dispersed, and then stirred and refluxed at 80°C for 12 hours to remove all the organic matter in the hybrid precursor. The resulting product is washed with deionized water and absolute ethanol successively After drying, cadmium sulfide nanorods can be obtained.

[0031] More preferably, in the first step, chromium nitrate tetrahydrate and thiourea are dispersed in the ethylenediamine solution at a molar ratio of 1:3, and stirred at room temperature for 30 minutes to make them evenly mixed; the reaction kettle...

Embodiment 1

[0036] (1) Synthesis of CdS nanorod precursor

[0037] Weigh 6.46mmol of chromium nitrate tetrahydrate and 19.38mmol of thiourea and disperse them in a 0.86mol / L ethylenediamine solution, stir for 30min at room temperature to make it evenly mixed; then transfer to the reactor, cover and seal, and put The stainless steel sleeve is tightly locked, the temperature is raised to 160 DEG C, and the temperature is kept for 60 hours. The obtained yellow powder is washed with deionized water and absolute ethanol and dried to obtain a hybrid precursor.

[0038] (2) Synthesis of CdS nanorods

[0039] Take 40 mg of the obtained hybrid precursor and disperse it in 150 ml of deionized water for ultrasonic dispersion, then stir and reflux at 80°C for 12 hours to remove all the organic matter in the hybrid precursor. The resulting product is washed with deionized water and absolute ethanol for 3 times. , Transferred to a 60°C vacuum drying oven and dried for 12 hours, and the obtained cadmium sulfi...

Embodiment 2

[0058] (1) Synthesis of CdS nanorod precursor

[0059] Weigh 5.81mmol of chromium nitrate tetrahydrate and 17.43mmol of thiourea and disperse them in a 0.86mol / L ethylenediamine solution, stir for 30min at room temperature to make them evenly mixed; then transfer to the reactor, cover and seal, and put The stainless steel sleeve is tightly locked, the temperature is raised to 135° C., and the temperature is kept for 15 hours. The obtained yellow powder is washed with deionized water and absolute ethanol and dried to obtain a hybrid precursor.

[0060] (2) Synthesis of CdS nanorods

[0061] Take 40 mg of the obtained hybrid precursor and disperse it in 150 ml of deionized water for ultrasonic dispersion, then stir and reflux for 12 hours at 80°C to remove all the organic matter in the hybrid precursor. The resulting product is washed with deionized water and absolute ethanol for 4 times. , Transferred to a vacuum drying oven at 60° C. and dried for 10 hours, and the obtained cadmium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com