A connection method of steel material and carbon fiber braid

A technology of carbon fiber weaving and connecting method, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of damage to composite material structure, low production efficiency, and waste of materials, so as to avoid the damage of epoxy resin and minimize the Effects of weight reduction and process difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Embodiment 1: In this embodiment, a method for connecting a steel material and a carbon fiber braid is specifically carried out in the following steps:

[0027] 1. Use carbon fiber weaving device to weave carbon fiber to obtain carbon fiber cloth;

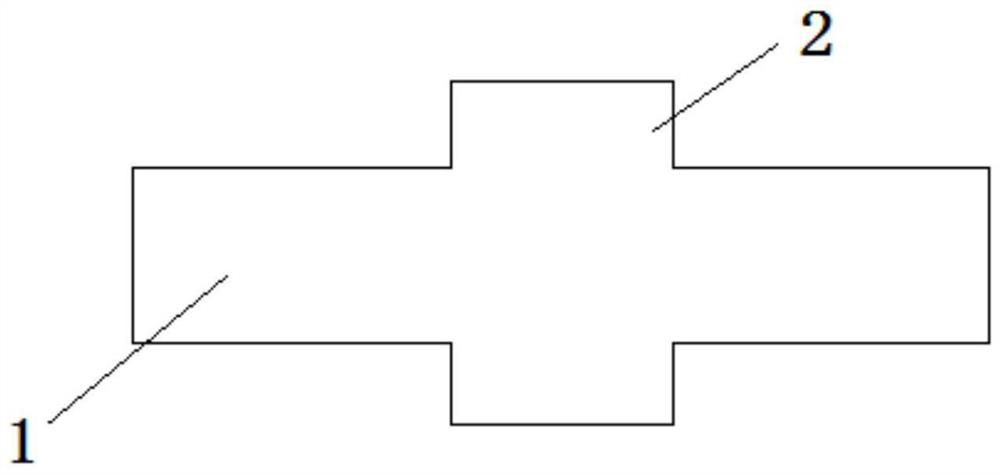

[0028] 2. Process the steel into a connecting body; the connecting body is composed of a main body and a connecting protrusion, and the connecting protrusions are respectively located on the upper surface and the lower surface of the main body;

[0029] 3. Cut out holes in the carbon fiber cloth obtained in step 1;

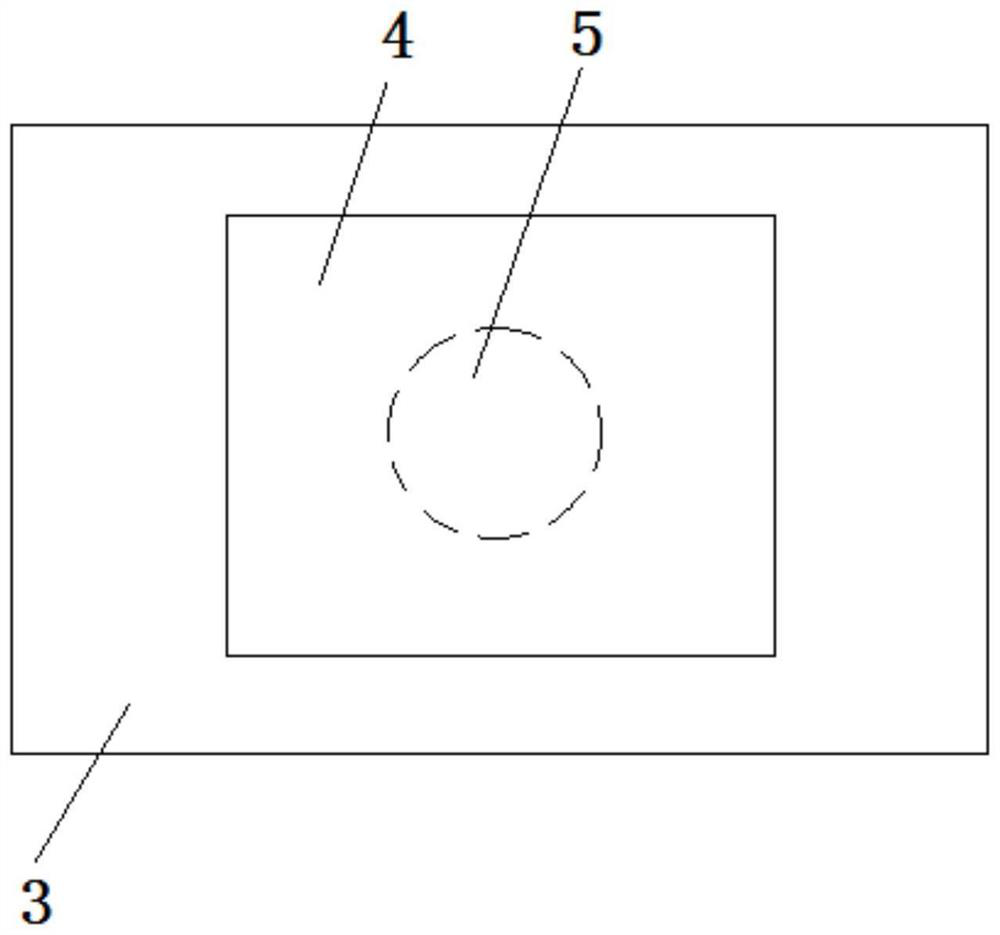

[0030] 4. Pretreat the connected body obtained in step 2, and then wrap the connected body with glass fiber cloth to expose the raised end face of the connection, and then pave it with the carbon fiber cloth cut in step 3 on the wet molding mold. Obtain the carbon fiber cloth paving body embedded with the connector, then close the mold, inject preheated epoxy resin, perform molding by wet molding process, open ...

specific Embodiment approach 2

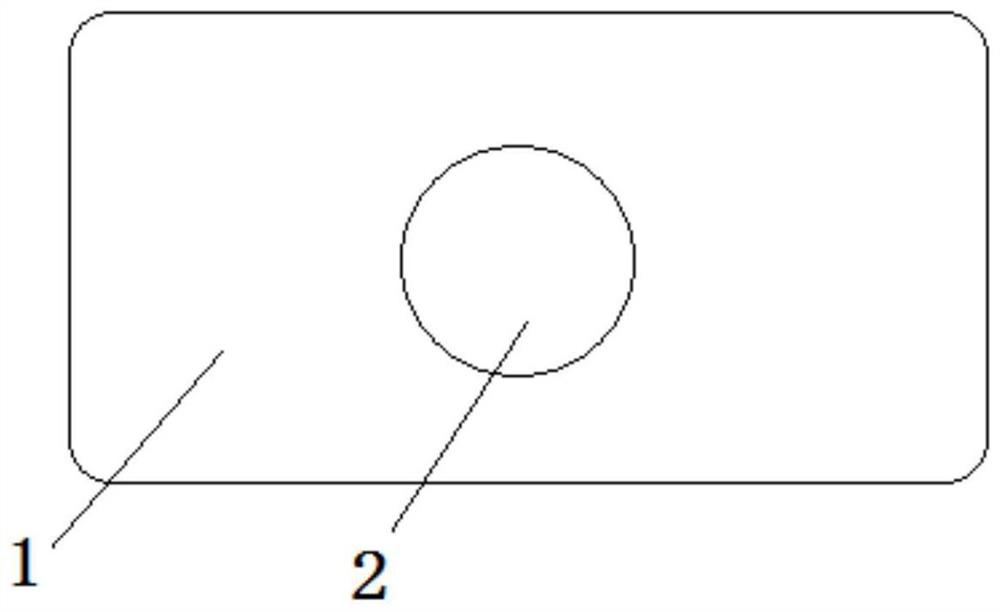

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the main body of the connecting body in step 2 is a rectangular structure with rounded corners, and the connecting protrusion is a cylinder with a height of 1.5-3 mm. The diameter of the bottom surface is 10-15 mm. Others are the same as in the first embodiment.

[0033] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 or 2 is that the density of the carbon fiber cloth after cutting in step 3 is 0.2-0.8 g / cm 3 . Others are the same as in the first or second embodiment.

specific Embodiment approach 4

[0034] Embodiment 4: The difference between this embodiment and one of Embodiments 1 to 3 is that the hole cut out in step 3 matches the connecting body. Others are the same as those in the first to third specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com