A multi-comb warp knitting machine steel pattern comb electronic traverse device

A technology of traversing device and warp knitting machine, which is applied in warp knitting, textiles, papermaking, knitting, etc. It can solve the problems of increasing equipment cost and operating cost, which is not conducive to the production speed of warp knitting machine, and is not conducive to saving energy. Achieve the effect of saving storage and maintenance, wide range of pattern lateral movement, and reducing the possibility of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

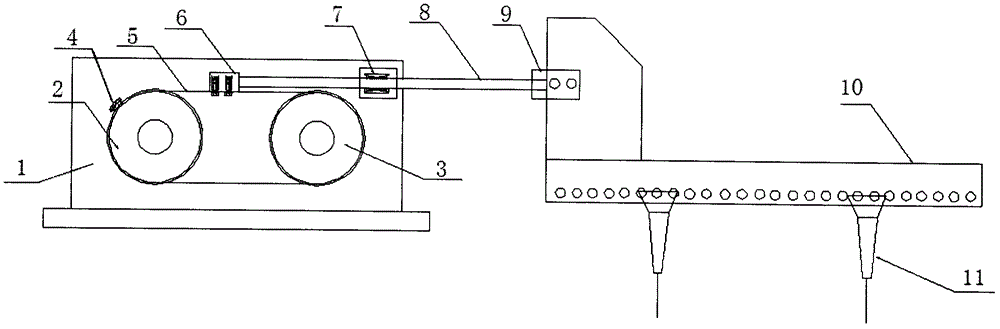

[0012] In the figure, 1 is the base of the traverse mechanism, 2 is the driving wheel, 3 is the steel wheel, 4 is the fixer, 5 is the aramid push-pull belt, 6 is the coupling, 7 is the guiding linear bearing, 8 is the ejector rod, and 9 is the comb Comb connecting pin, 10 is a steel sheet floral comb, and 11 is a guide needle.

[0013] As shown in the figure: the steel patterned comb electronic traverse device of the present invention is used as a steel patterned comb of a multi-bar warp knitting machine, and multiple groups of steel patterned comb electronic traverse devices can be installed on the multi-bar warp knitting machine. A traverse mechanism base 1 is installed on the upper frame of the multi-bar warp knitting machine. The servo motor for traversing transmission is installed on the base 1 of the traversing mechanism, and the driving wheel 2 can be directly installed on the output shaft of the traversing servo motor, or can be connected with it through a reducer. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com